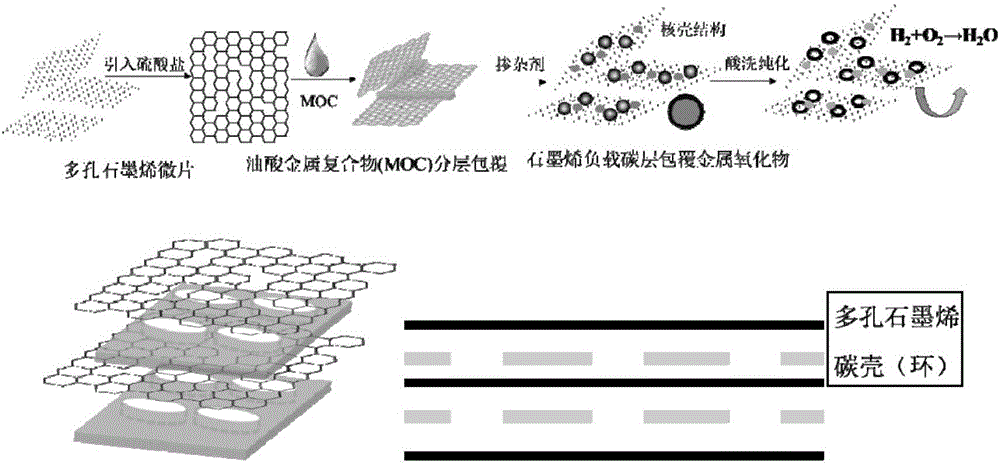

Preparation method of heteroatom doped graphene hierarchical pore carbon material

A graphene, multi-level pore technology, applied in graphene, chemical instruments and methods, nano-carbon, etc., can solve problems such as unfavorable large-scale production, high requirements, cost, high energy consumption, etc., and achieve rich pore size and three-dimensional transmission. The effect of mass channel, large working current, good methanol tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

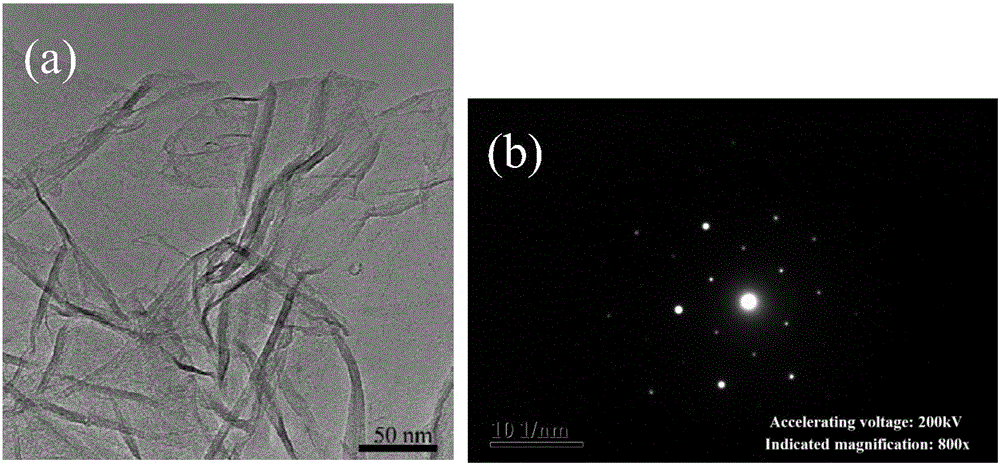

Embodiment 1

[0062] Application No. 201310659172.5, named as a method for preparing graphene from electrochemically swollen graphite, the carbon / oxygen atomic ratio of the graphene sample obtained in Example 2 of the patent is 71%, the graphene unit reaches 200 μm × 200 μm, and 70% of the graphite in the sample The number of ene layers is 2-3 atomic layers. Measure 100ml of graphene aqueous solution with a concentration of 10mg / ml, and prepare a stable graphene dispersion under ultrasonic conditions: 60W, 60min, and keep the temperature at 45°C; measure 1g of "pore-forming agent" ferrous sulfate, add 5ml of water, at room temperature, mechanically stirred for 3h until completely dissolved to a clear and transparent solution. The ferrous sulfate solution was poured into the graphene dispersion liquid, ultrasonically treated, the ultrasonic power was 60W, and the time was 90min, for mixing and dispersing; after that, it was mechanically stirred at room temperature for 12h to form a uniform g...

Embodiment 2

[0067] Adopt application number 201310659172.5, named as a method for preparing graphene by electrochemically swelling graphite. The carbon / oxygen atomic ratio of the graphene sample obtained in Example 4 in the patent is 70%, and the graphene layer number of 80% in the sample is 2-3 atomic layers. . Measure 100ml of graphene aqueous solution with a concentration of 5mg / ml, and prepare a stable graphene dispersion under ultrasonic conditions: 150W, 30min, and keep the temperature at 50°C; measure 1.5g of "pore-forming agent" ferrous sulfate, add 10ml of water, at room temperature, mechanically stirred for 1h until completely dissolved to a clear and transparent solution. The ferrous sulfate solution was poured into the graphene dispersion liquid, ultrasonically treated, the ultrasonic power was 150W, and the time was 60min, for mixing and dispersing; after that, it was mechanically stirred at room temperature for 6h to form a uniform graphene / ferrous sulfate mixture.

[0068]...

Embodiment 3

[0072] Application No. 201310659172.5, named as a method for preparing graphene from electrochemically swollen graphite, the carbon / oxygen atomic ratio of the graphene sample obtained in Example 5 of the patent is 73%, the graphene unit reaches 200 μm × 200 μm, and 70% of the graphite in the sample The number of ene layers is 2-3 atomic layers. Measure 100ml of a graphene aqueous solution with a concentration of 5mg / ml, and prepare a stable graphene dispersion under ultrasonic conditions: 100W, 45min, and keep the temperature at 30°C; measure 1g of "pore-forming agent" magnesium sulfate, and add it to 10ml of water , at room temperature, mechanically stirred for 30min until completely dissolved to a clear transparent solution. The magnesium sulfate solution was poured into the graphene dispersion liquid, ultrasonically treated, the ultrasonic power was 100W, and the time was 90min, for mixing and dispersing; after that, it was mechanically stirred at room temperature for 8h to...

PUM

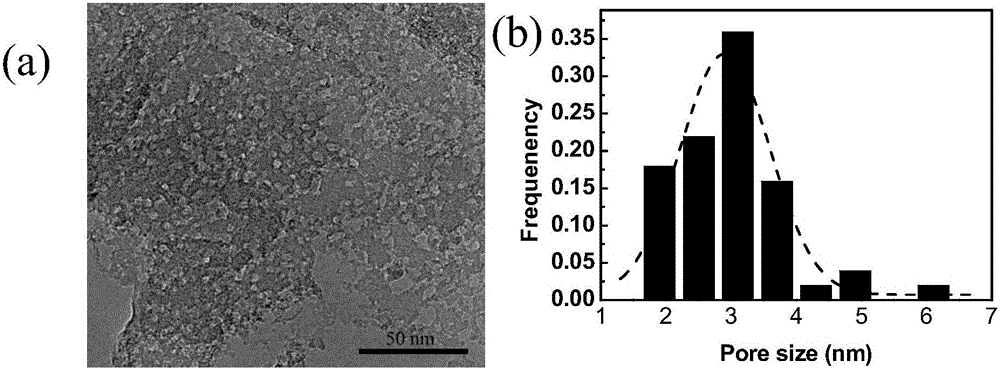

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com