Method for etching graphene nanopores to reduce secondary electron emission coefficient

A secondary electron emission and graphene nanopore technology, which is applied in the field of etching graphene nanopores to reduce the secondary electron emission coefficient, can solve problems such as poor stability, and achieve chemical oxidation avoidance, simple technical solutions, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

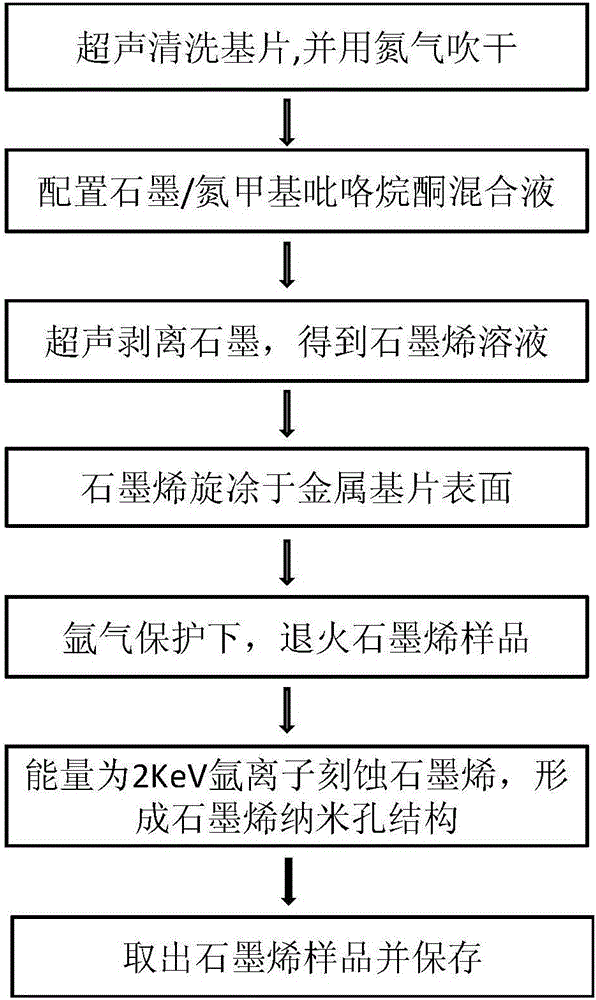

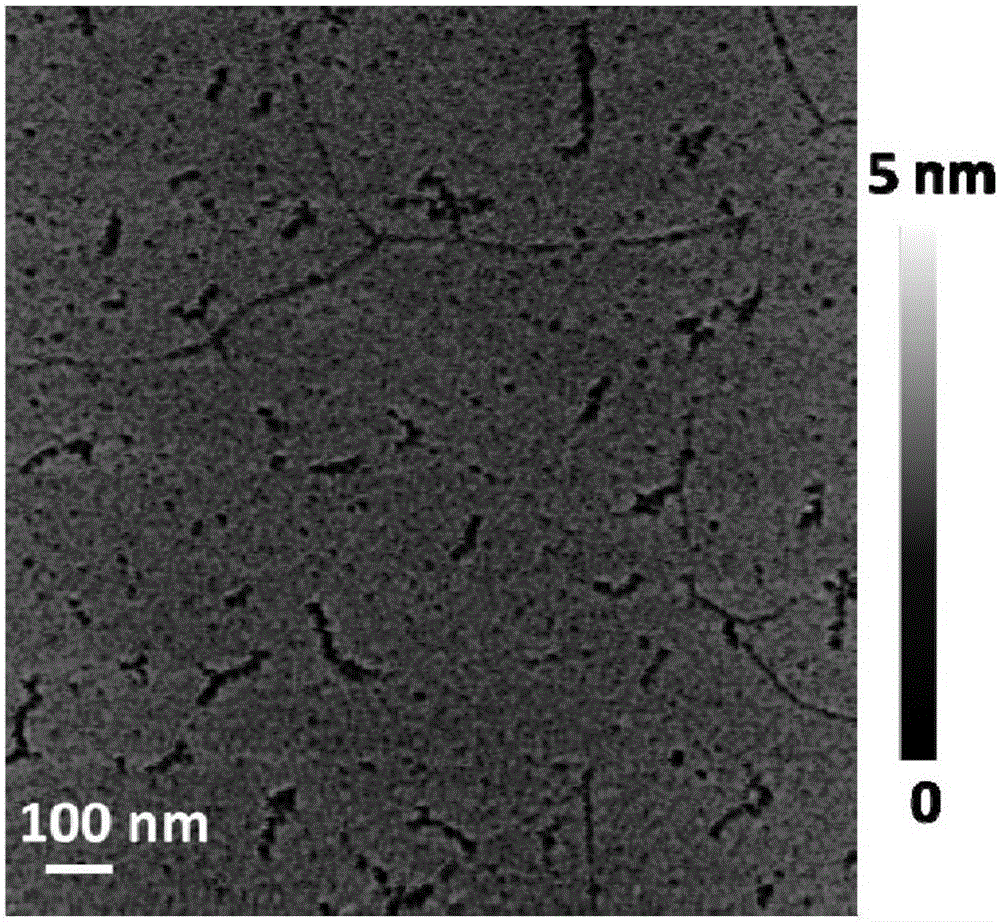

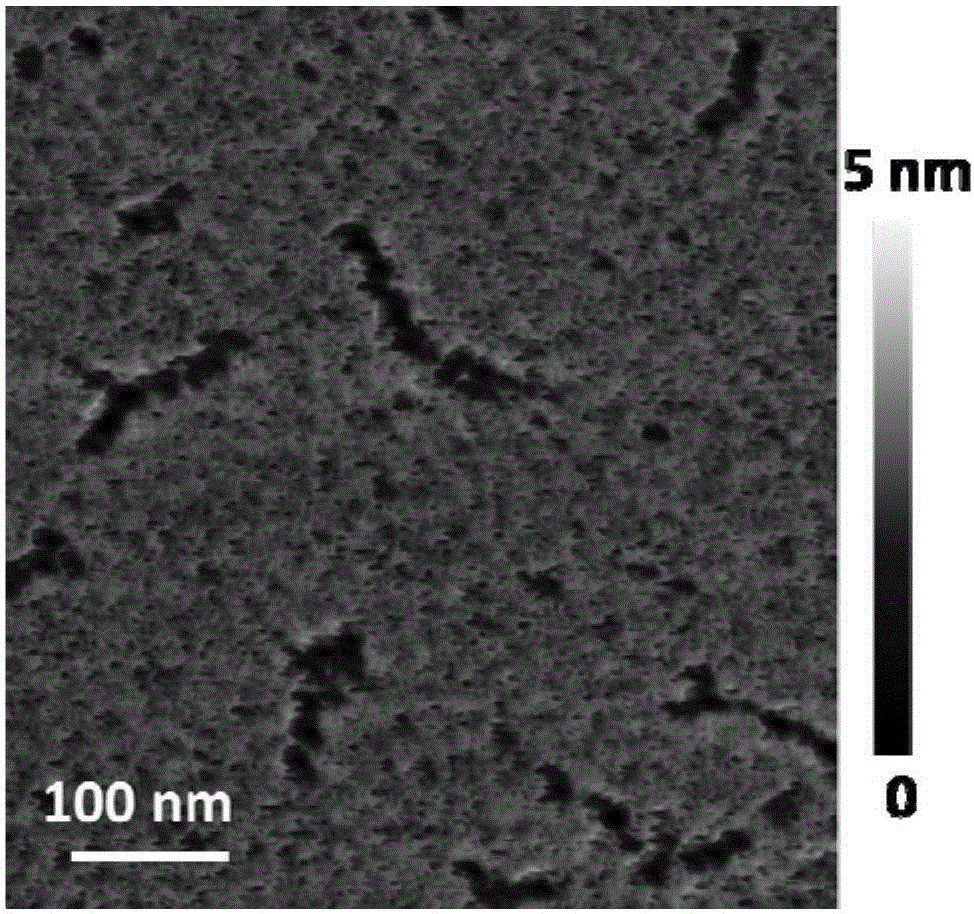

[0026] The specific idea of the present invention is as follows: a method for etching graphene nanopores to reduce the secondary electron emission coefficient, comprising the steps of ultrasonically cleaning the metal substrate with acetone and alcohol for 20-60 minutes, and blowing dry with nitrogen; Ultrasonic method is used to configure the nitrogen methyl pyrrolidone solution with a concentration of 0.1-1mg / ml graphene; apply 0.05-0.3ml graphene solution on the substrate by spin coating to form a graphene film with nanometer thickness on the surface; 300- At 500°C, the substrate was annealed under the protection of nitrogen for 1 hour to remove residual organic matter on the surface; the substrate was placed in an argon ion etching system, and the graphene was etched for 30s-2 minutes with ions with an energy of 1-5KeV. Graphene nanopores are formed; finally, the samples are removed and preserved. The secondary electron emission suppression effect depends on the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com