Substrate-active layer composite nano photonics structure alkali metal compound photocathode

A technology of alkali metal compounds and nanophotons, which is applied in the manufacture of light-emitting cathodes, optics, optical components, etc., and can solve problems such as reducing light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

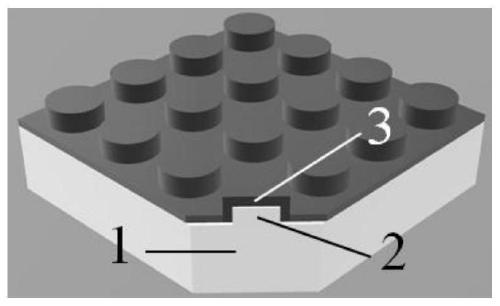

[0054] like figure 1 As shown, a substrate-active layer composite nano-cylindrical array photonics structure alkali metal compound photocathode, including substrate 1, nano-cylindrical array 2 and alkali metal compound active layer 3, the excitation light is active from the alkali metal compound The upper surface of the layer 3 is incident or incident from the lower surface of the substrate 1. When the light is incident from the lower surface of the substrate 1, the substrate 1 is made of a light-transmitting material. The process flow is as follows: firstly, the surface of the substrate 1 is Pretreatment, and then directly etching the upper surface of the substrate 1 to prepare the nano-cylindrical array 2, and finally depositing the alkali metal compound active layer 3 on the upper surface of the nano-cylindrical array 2; the specific preparation steps are as follows:

[0055] Step 1) Prepare the substrate 1

[0056] Prepare a circular SiO with a diameter of 3 inches and a ...

Embodiment 2

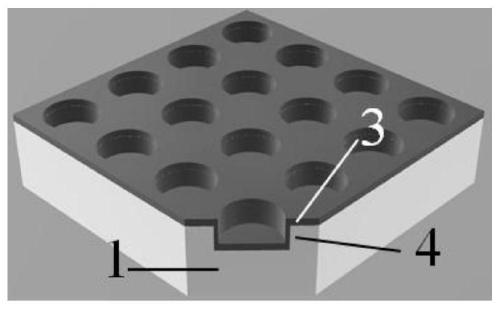

[0069] like figure 2 As shown, a substrate-active layer composite nano-cylindrical hole array photonics structure alkali metal compound photocathode, including a substrate 1, a nano-cylindrical hole array 4 and an alkali metal compound active layer 3, the laser is emitted from the alkali metal compound The upper surface of the source layer 3 is incident or incident from the lower surface of the substrate 1. When the light is incident from the lower surface of the substrate 1, the substrate 1 is made of a light-transmitting material. The process flow is as follows: firstly, the surface of the substrate 1 Perform pretreatment, then directly etch the upper surface of the substrate 1 to prepare the nano-cylindrical hole array 4, and finally deposit and prepare the alkali metal compound active layer 3 on the upper surface of the nano-cylindrical hole array 4; the specific preparation steps are as follows:

[0070] Step 1) Prepare the substrate 1

[0071] Prepare a circular SiO wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com