A method for multi-stage hydrogen peroxide to remove organic matter in alumina production process

A production process, hydrogen peroxide technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of reduced seed crystal decomposition rate, fragility, and impact on seed crystal decomposition, etc., to achieve good removal effect, high solubility, and high utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

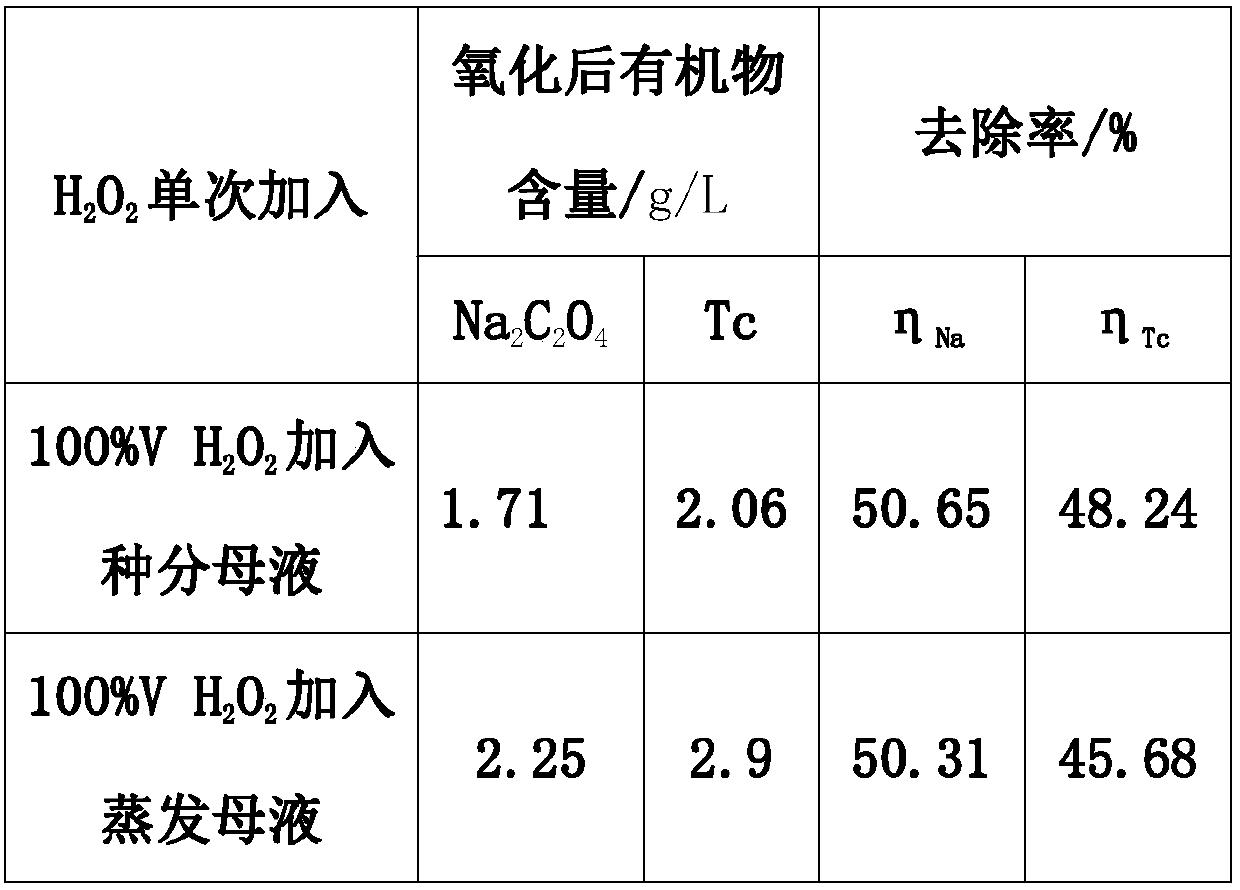

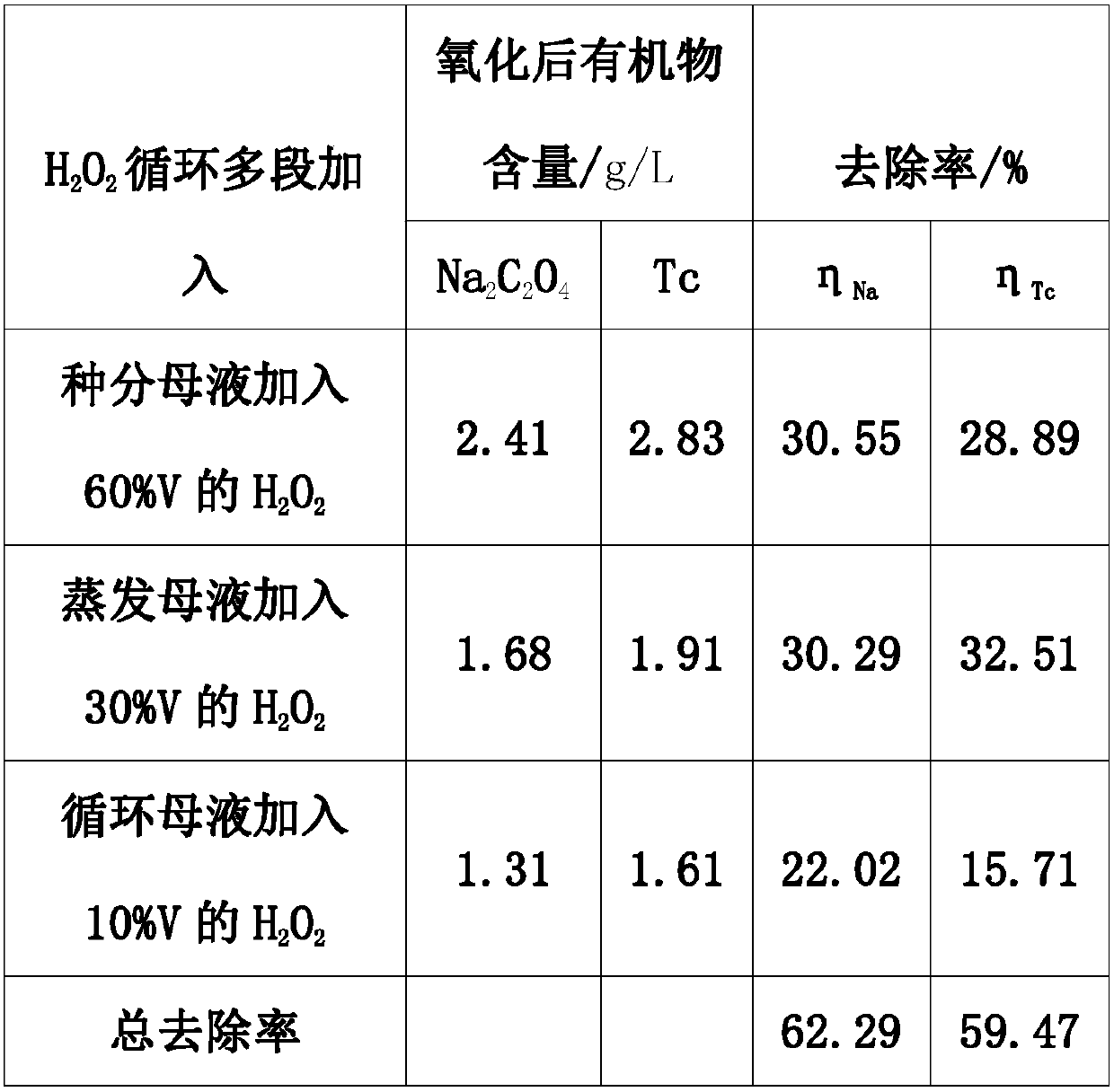

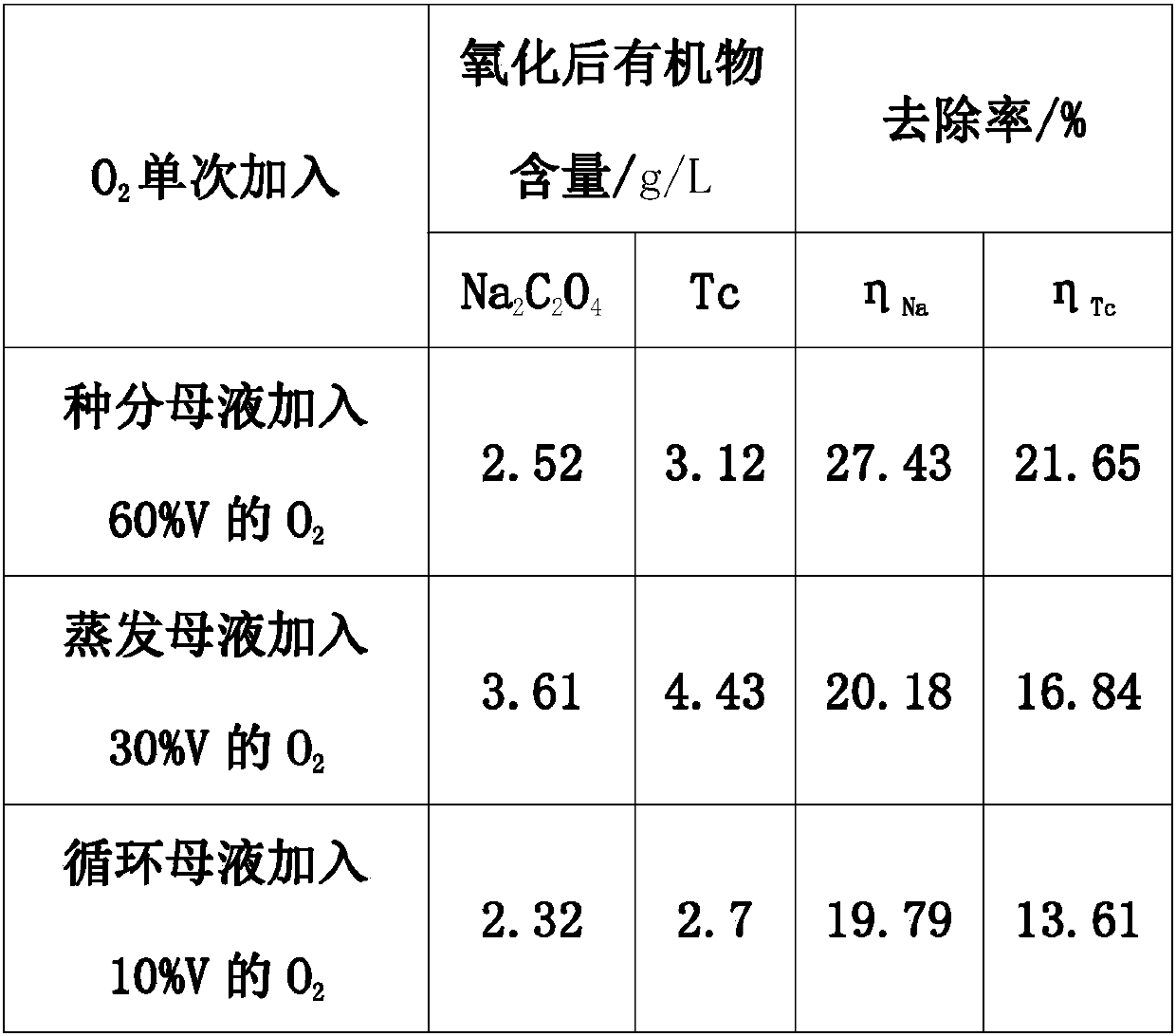

[0050] Embodiment 1: a kind of method that multistage hydrogen peroxide removes the organic matter in alumina production process, steps are as follows:

[0051] (1) Injecting the leaching solution into the bauxite, leaching the alumina in the bauxite to obtain a sodium aluminate solution, decomposing the solution seed crystals and filtering to obtain the seed mother liquor;

[0052] (2) get described kind divide mother liquor, represent the content of organic matter with the total carbon concentration in kind divide mother liquor, by formula Calculate the total volume V of hydrogen peroxide required for the reaction (C in the formula TC is the total carbon concentration in the mother liquor, V 0 is the total volume of seed liquor, C H2O2 is hydrogen peroxide concentration, b is excess coefficient), wherein the value range of b is 0.5;

[0053] (3) Add 60% hydrogen peroxide of the total volume V in the mother liquor of seed separation, react for 30min, after the reaction, t...

Embodiment 2

[0056] Embodiment 2: a kind of method that multi-stage hydrogen peroxide removes the organic matter in the aluminum oxide production process, the steps are as follows:

[0057] (1) Injecting the leaching solution into the bauxite, leaching the alumina in the bauxite to obtain a sodium aluminate solution, decomposing the solution seed crystals and filtering to obtain the seed mother liquor;

[0058] (2) get described kind divide mother liquor, represent the content of organic matter with the total carbon concentration in kind divide mother liquor, by formula Calculate the total volume V of hydrogen peroxide required for the reaction (C in the formula TC is the total carbon concentration in the mother liquor, V 0 is the total volume of seed liquor, C H2O2 is hydrogen peroxide concentration, b is excess coefficient), wherein the value range of b is 0.1;

[0059] (3) Add 70% hydrogen peroxide of the total volume V to the seed separation mother liquor, react for 60min, and afte...

Embodiment 3

[0062] Embodiment 3: a kind of method that multistage hydrogen peroxide removes the organic matter in alumina production process, steps are as follows:

[0063] (1) Injecting the leaching solution into the bauxite, leaching the alumina in the bauxite to obtain a sodium aluminate solution, decomposing the solution seed crystals and filtering to obtain the seed mother liquor;

[0064] (2) get described kind divide mother liquor, represent the content of organic matter with the total carbon concentration in kind divide mother liquor, by formula Calculate the total volume V of hydrogen peroxide required for the reaction (C in the formula TC is the total carbon concentration in the mother liquor, V 0 is the total volume of seed liquor, C H2O2 is hydrogen peroxide concentration, b is excess coefficient), wherein the value range of b is 1;

[0065] (3) Add 50% hydrogen peroxide of the total volume V to the seed separation mother liquor, react for 1min, and after the reaction, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com