Environmental-friendly high-temperature resistant impregnated resin and applications thereof

A technology of impregnating resin and high temperature resistance, which is applied in the field of environmental protection and high temperature resistant impregnating resin, which can solve the problems of high brittleness, poor storage stability, and poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

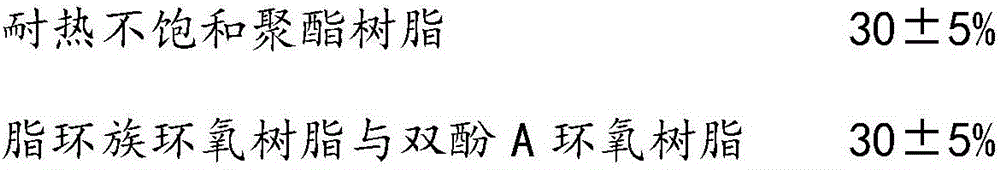

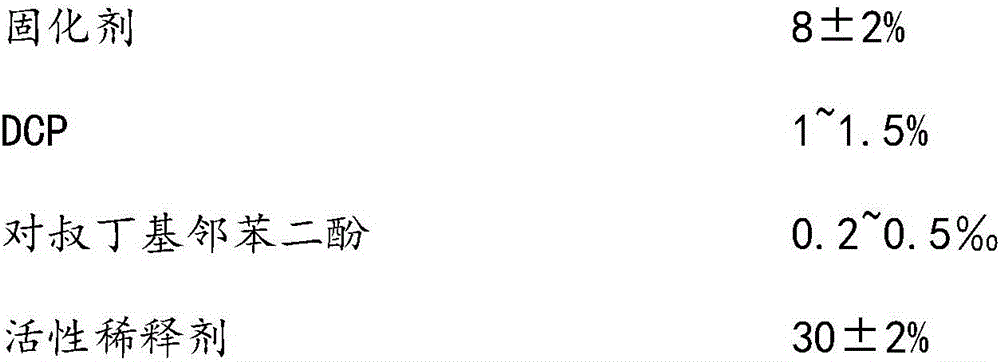

[0045] A kind of environment-friendly high temperature resistant impregnating resin, its composition and weight percentage are as follows:

[0046]

[0047]

[0048] Wherein said bisphenol A epoxy resin is a kind of in E-42, E-44, E-51.

[0049] The reactive diluent is a low-volatility reactive diluent, which is one or more of alkyl glycidyl ether, cresyl glycidyl ether, castor oil polyglycidyl ether, and the low-volatility reactive diluent improves the viscosity of the resin. Saturation vapor pressure and flash point, and help to improve the vacuum degree of VPI impregnation.

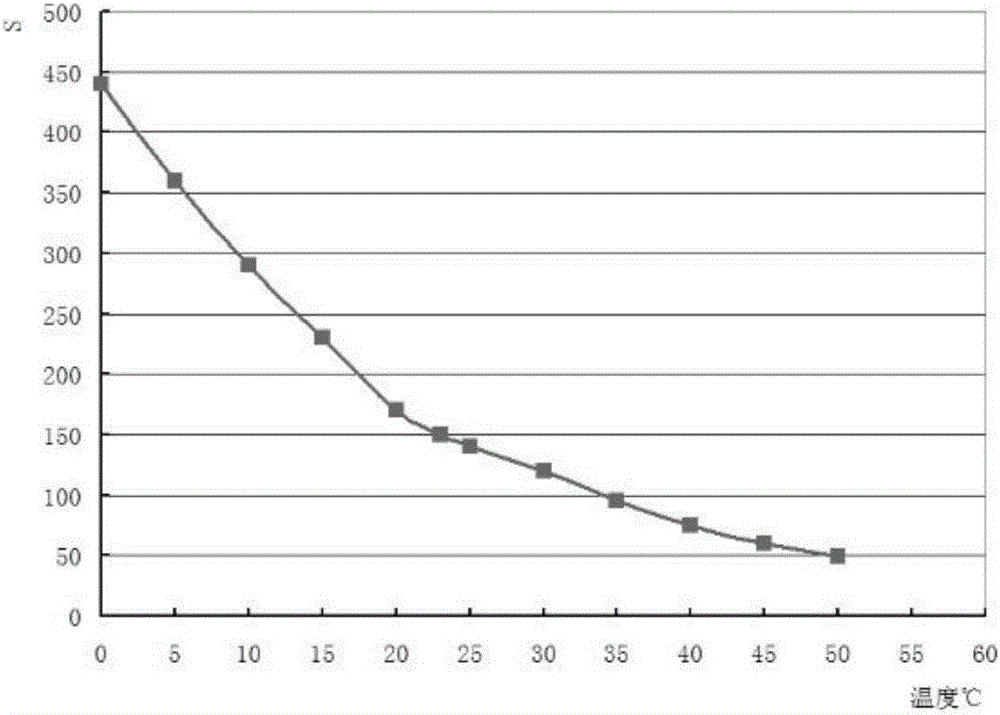

[0050] From figure 1 It can be seen that the viscosity of the environmental-friendly high-temperature resistant impregnating resin of the present invention decreases with the increase of temperature, and the viscosity at room temperature is relatively low.

[0051] The application of an environment-friendly and high-temperature-resistant impregnating resin in the insulation treatment of VPI coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com