UV-cured soft coating paint composition and preparation method thereof

A composition and coating technology, used in coatings, polyurea/polyurethane coatings, etc., can solve the problems of lack of coating film performance and optimized performance, and achieve the effect of fast curing speed and excellent film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

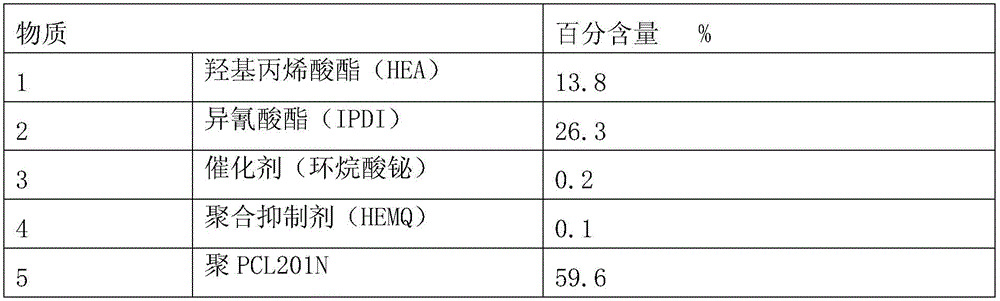

[0032] Embodiment 1 Synthetic oligomer urethane acrylate PAU1

[0033] The synthesis of oligomers was carried out according to the data listed in the table

[0034] Table 1 Oligomer synthesis formula

[0035]

[0036] Pump the above components 1, 3, and 4 into the reactor, add 2 components dropwise, control the temperature at 80-82°C for 4 hours, then add 5 components, react at 82-85°C for 8 hours, and detect NCO <0.2% can be discharged for later use.

[0037] The PAU1 related indicators: viscosity 20000mpa.s / 45°C; NCO: 0.15%.

Embodiment 2

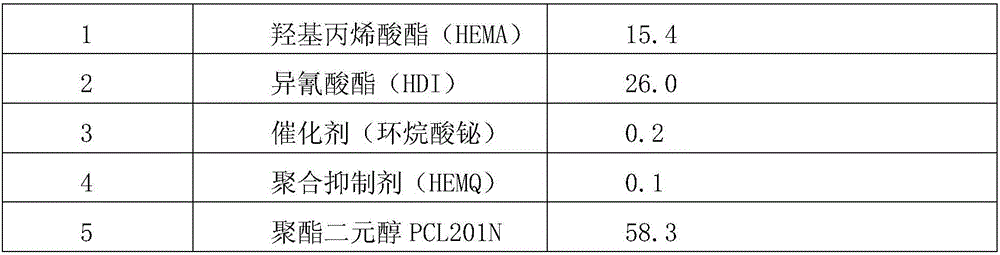

[0038] Embodiment 2 inner coating oligomer urethane acrylate PAU2

[0039] The synthesis of oligomers was carried out according to the data listed in the table

[0040] Table 2 Oligomer Synthetic Formula

[0041]

[0042]

[0043]Pump the above components 1, 3, and 4 into the reactor, add 2 components dropwise, control the temperature at 80-82°C for 4 hours, then add 5 components, react at 82-85°C for 8 hours, and detect NCO <0.2% can be discharged for later use.

[0044] The PAU2 related indicators: viscosity 18500mpa.s / 45°C; NCO: 0.10%.

Embodiment 3

[0045] Embodiment 3 prepares UV-curable soft coat paint

[0046] The coating is prepared according to the formula in Table 3.

[0047]

[0048] The above components are formulated into paint, and the relevant indicators measured are: viscosity 2500mpa.s / 25°C; fineness: <10um;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com