Wet-strength hot-melt adhesive for disposable hygienic product and preparation method thereof

A hygienic product and hot-melt adhesive technology, applied in the direction of adhesives, adhesive types, mineral oil hydrocarbon copolymer adhesives, etc., can solve the problem of the decrease of the bonding strength between polar materials and non-polar materials, polar materials and Unbalanced non-polar materials and other issues to achieve stable bonding, improve integrity and integrity, and reduce delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Naphthenic oil (4010 from Karamay), which accounts for 25% of the mass of the hot-melt adhesive, SIS1209, which accounts for 19% of the mass of the hot-melt adhesive, SBS188, which accounts for 5% of the mass of the hot-melt adhesive, and additive resin, which accounts for 5% of the mass of the hot-melt adhesive, Mix 0.7% antioxidant of hot melt adhesive evenly, heat to 140-150°C, continuously stir and evacuate to -0.08mpa, until completely melted, add C5 petroleum resin (Angstrom Kesen 5600), keep the heating temperature at 130-140°C, stir evenly, wait until completely melted, vacuumize until there are no bubbles, and the resulting mixture is a wet-strength adhesive for disposable sanitary products.

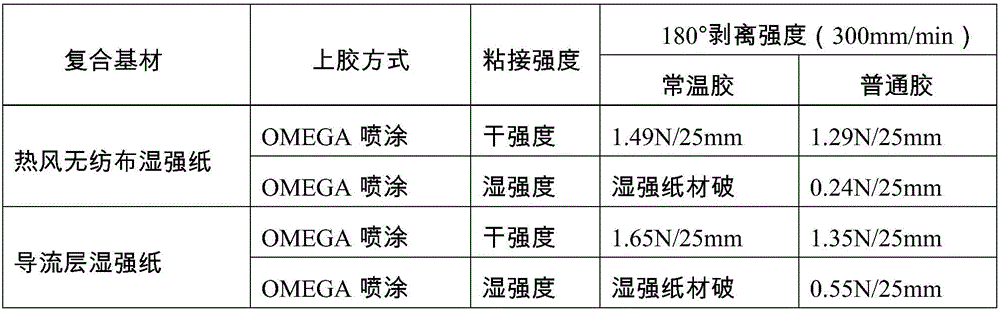

[0034] The hot melt adhesive prepared in this example is suitable for spraying and scraping gluing devices. The specific glue temperature is 150-155°C for the glue tank, 155-160°C for the throat, 160-165°C for the nozzle, and the glue amount is 3g / m 2 , the bonding stre...

Embodiment 2

[0038] Naphthenic oil (4010 from Karamay), which accounts for 30% of the mass of the hot melt adhesive, SBS1301 rubber which accounts for 3% of the mass of the hot melt adhesive, SIS1209 rubber which accounts for 10% of the mass of the hot melt adhesive, and SIS1126 which accounts for 3% of the mass of the hot melt adhesive Mix rubber and 0.3% antioxidant (1010) by mass of hot melt adhesive evenly, heat to 140-150°C, and continuously stir and vacuumize to -0.08mpa. After completely melting, add 15% of hot melt adhesive mass C5 petroleum resin, add rosin resin PER-100L accounting for 33.7% of the mass of the hot melt adhesive, add additive resin accounting for 5% of the mass of the hot melt adhesive, keep the heating temperature at 120-130°C, stir evenly, wait until it is completely melted, and then vacuumize Until there are no air bubbles, the resulting mixture is a wet-strength adhesive for disposable hygiene products.

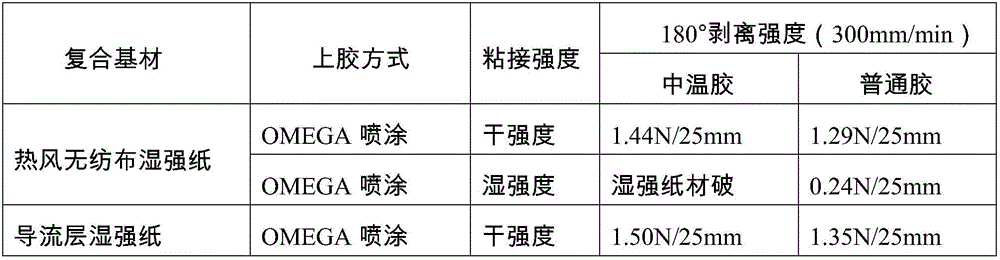

[0039] The hot melt adhesive prepared in this example i...

Embodiment 3

[0044] Naphthenic oil (4010 produced by Karamay), accounting for 30% of the quality of hot melt adhesive, SEBS accounting for 7.5% of the quality of hot melt adhesive, SBS accounting for 7.5% of the quality of hot melt adhesive, and 0.3% of the quality of hot melt adhesive Antioxidant (1010 ) mix evenly, heat to 140-150°C, and continuously stir and evacuate to -0.08mpa. After it is completely melted, add additive resin accounting for 7% of the mass of the hot melt adhesive, and add C5 petroleum accounting for 18% of the mass of the hot melt adhesive Resin, add rosin resin accounting for 29.7% of the mass of the hot melt adhesive, keep the heating temperature at 120-130°C, stir evenly, wait until it is completely melted, and vacuum until there are no bubbles. The resulting mixture is a wet-strength adhesive for disposable hygiene products.

[0045] The hot melt adhesive prepared in this example is suitable for spraying and scraping gluing devices. The specific glue temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com