Aluminum-magnesium-silicon alloy for control arm of domestic automobile and preparation method thereof

A family car, aluminum-magnesium-silicon technology, which is applied in the field of aluminum-silicon-magnesium alloys, can solve problems such as suboptimal alloy formulations, reduced corrosion resistance, and increased production costs, and achieve the goals of improving various performances, reducing weight, and saving costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

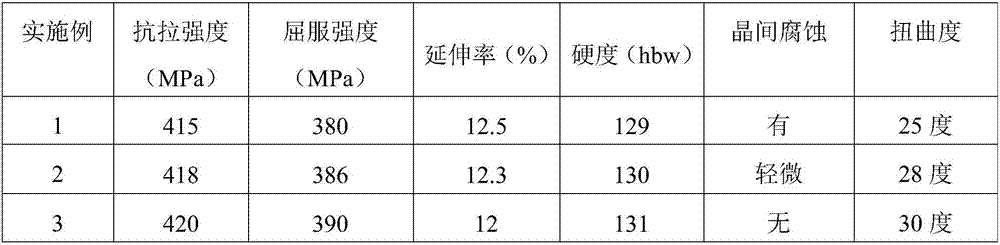

Examples

Embodiment 1

[0024] The applicant provides an aluminum-magnesium-silicon alloy for the control arm of a family car, which is composed of the following raw materials: silicon: 110kg, copper: 4kg, manganese: 70kg, magnesium: 70kg, chromium: 16kg, zirconium: 2kg, aluminum: 9728kg .

[0025] The preparation method of the aluminum-magnesium-silicon alloy is:

[0026] (1) First put the aluminum ingot into the melting furnace for melting, the melting temperature control range is 760°C, and the melting time is 3 hours, open the furnace door and rake the ash into the bottom of the furnace to see if it is completely melted; after all the materials in the furnace are completely melted , turn on the electromagnetic stirring device, and stir for 15 minutes;

[0027] (2) Then add a refining agent, carry out the first refining of the aluminum liquid with nitrogen at a pressure of 0.08-0.12Mpa for 20 minutes, and then carry out slag removal;

[0028] (3) After removing slag, add copper, manganese, chrom...

Embodiment 2

[0034] The applicant provides an aluminum-magnesium-silicon alloy for the control arm of a family car, which is composed of the following raw materials: silicon: 125kg, copper: 8kg, manganese: 85kg, magnesium: 90kg, chromium: 20kg, zirconium: 4kg, aluminum: 9668kg .

[0035] The preparation method of the aluminum-magnesium-silicon alloy is:

[0036] (1) First put the aluminum ingot into the melting furnace for melting, the melting temperature control range is 720°C, and the melting time is 4 hours, open the furnace door and rake the ash into the bottom of the furnace to see if it is completely melted; after all the materials in the furnace are completely melted , turn on the electromagnetic stirring device, and stir for 20 minutes;

[0037] (2) Add refining agent then, carry out first refining 15 minutes to molten aluminum with the nitrogen of pressure 0.08-0.12Mpa, then carry out slag removal;

[0038] (3) After removing slag, add copper, manganese, chromium, zirconium allo...

Embodiment 3

[0044] The applicant provides an aluminum-magnesium-silicon alloy for the control arm of a family car, which is composed of the following raw materials: silicon: 119kg, copper: 6kg, manganese: 80kg, magnesium: 80kg, chromium: 18kg, zirconium: 3kg, aluminum: 9694kg .

[0045] The preparation method of the aluminum-magnesium-silicon alloy is:

[0046] (1) First put the aluminum ingot into the melting furnace for melting, the melting temperature control range is 740°C, and the melting time is 3.5 hours. Open the furnace door and rake the ash into the bottom of the furnace to see if it is completely melted; after all the materials in the furnace are completely melted , turn on the electromagnetic stirring device, and stir for 18 minutes;

[0047] (2) Then add a refining agent, use nitrogen with a pressure of 0.08-0.12Mpa to refine the aluminum liquid for the first time for 15-20 minutes, and then carry out slag removal;

[0048] (3) After removing slag, add copper, manganese, ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com