Process method of electrochemically preparing Fe3+ and H2 in pair

A process method and electrochemical technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of difficult regeneration, large energy consumption, system pollution, etc., and achieve high efficiency and energy utilization rate, high energy utilization rate, and current high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

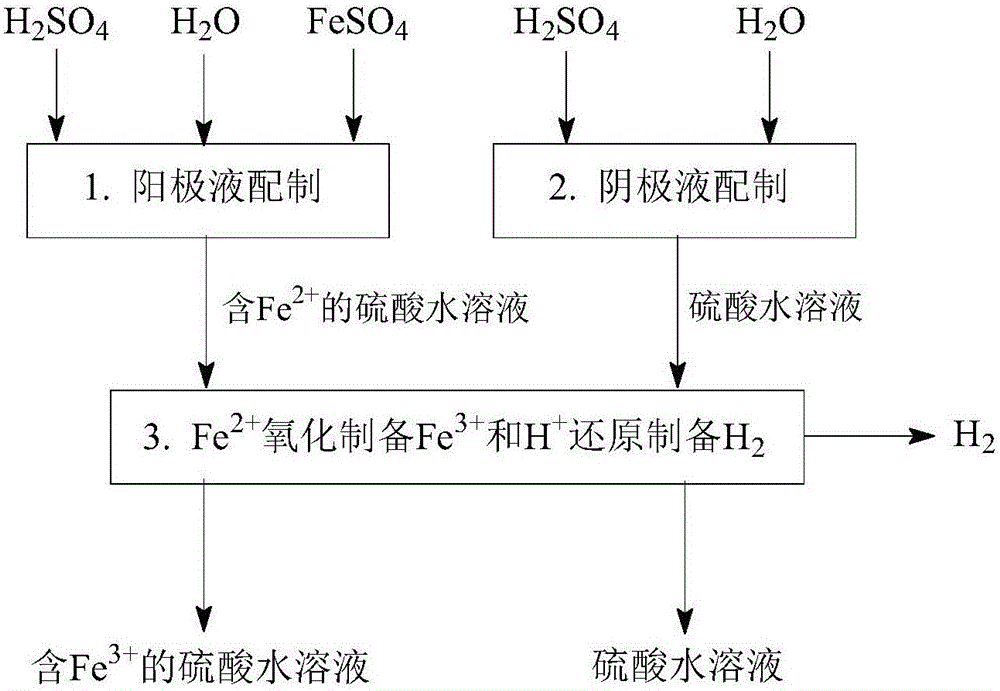

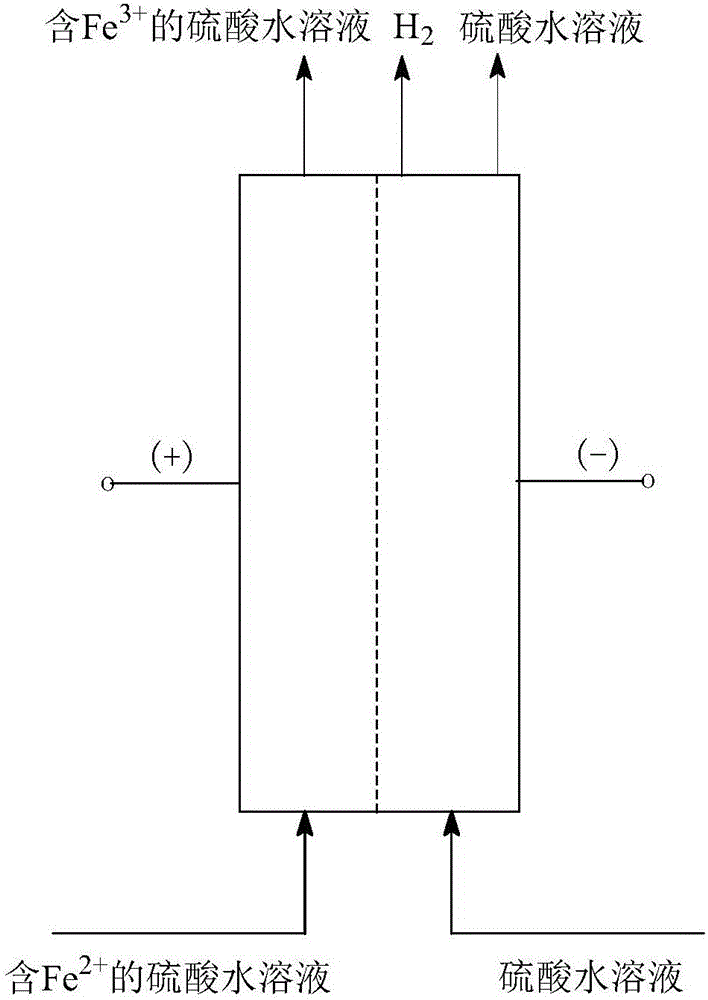

[0092] Such as figure 1 and figure 2 As shown, a paired electrochemical preparation of Fe 3+ and H 2 The process method, the concrete steps are as follows:

[0093] (1) Preparation of anolyte: mix sulfuric acid with water to obtain an aqueous solution of sulfuric acid, then dissolve ferrous sulfate in the aqueous solution of sulfuric acid to obtain a solution containing 0.2mol / L H 2 SO 4 and 0.2mol / L Fe 2+ The anolyte, the operating temperature is 20 ℃.

[0094] (2) Preparation of catholyte: mix sulfuric acid with water to obtain 0.2mol / L H 2 SO 4 The aqueous solution is used as catholyte, and the operating temperature is 20°C.

[0095] (3) Fe 2+ Oxidation to produce Fe 3+ and H + Reduction to prepare H 2 : In an electrochemical reactor with a sulfonic acid type cation exchange membrane as a separator, sulfuric acid as a supporting electrolyte, and flat PbO 2 The electrode is an anode, and the operating current density is 10mA / cm 2 , the operating temperature is...

Embodiment 2

[0097] Such as figure 1 and figure 2 As shown, a paired electrochemical preparation of Fe 3+ and H 2 The process method, the concrete steps are as follows:

[0098] (1) Anolyte preparation: will contain Fe 3+ The sulfuric acid aqueous solution is mixed with sulfuric acid and water, and then ferrous sulfate is dissolved in the solution to obtain a solution containing 8.0mol / L H 2 SO 4 , 2.0mol / L Fe 2+ and Fe 3+ For the anolyte with concentration ≤0.2mol / L, the operating temperature is 60°C.

[0099] (2) catholyte preparation: will contain Fe 3+ and Fe 2+ Sulfuric acid aqueous solution is mixed with sulfuric acid and water to prepare 6.0mol / LH 2 SO 4 , 0.02mol / L Fe 2+ and 0.02mol / L Fe 3+ Concentration of catholyte, the operating temperature is 60 ℃.

[0100] (3) Fe 2+ Oxidation to produce Fe 3+ and H + Reduction to prepare H 2 : In an electrochemical reactor with a sulfonic acid cation exchange membrane as a separator, sulfuric acid as a supporting electrolyte...

Embodiment 3

[0102] Such as figure 1 and figure 2 As shown, a paired electrochemical preparation of Fe 3+ and H 2 The process method, the concrete steps are as follows:

[0103] (1) Anolyte preparation: will contain Fe 3+ The sulfuric acid aqueous solution is mixed with sulfuric acid and water, and then ferrous sulfate is dissolved in the solution to obtain a solution containing 1.0mol / L H 2 SO 4 , 0.4mol / L Fe 2+ and 0.2mol / L Fe 3+ The anolyte, the operating temperature is 40 ℃.

[0104] (2) catholyte preparation: will contain Fe 3+ and Fe 2+ Sulfuric acid aqueous solution is mixed with sulfuric acid and water to prepare 4.0mol / LH 2 SO 4 , 0.01mol / L Fe 2+ and 0.02mol / L Fe 3+ The catholyte, the operating temperature is 40 ℃.

[0105] (3) Fe 2+ Oxidation to produce Fe 3+ and H + Reduction to prepare H 2 : In an electrochemical reactor with a sulfonic acid type cation exchange membrane as a separator, sulfuric acid as a supporting electrolyte, and a graphite three-dimension...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com