Automatic idling system based on multiple hydraulic accumulators and control method

A hydraulic accumulator, automatic technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of long hydraulic circuit, high cost, and it is difficult to greatly improve the effective utilization rate of energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

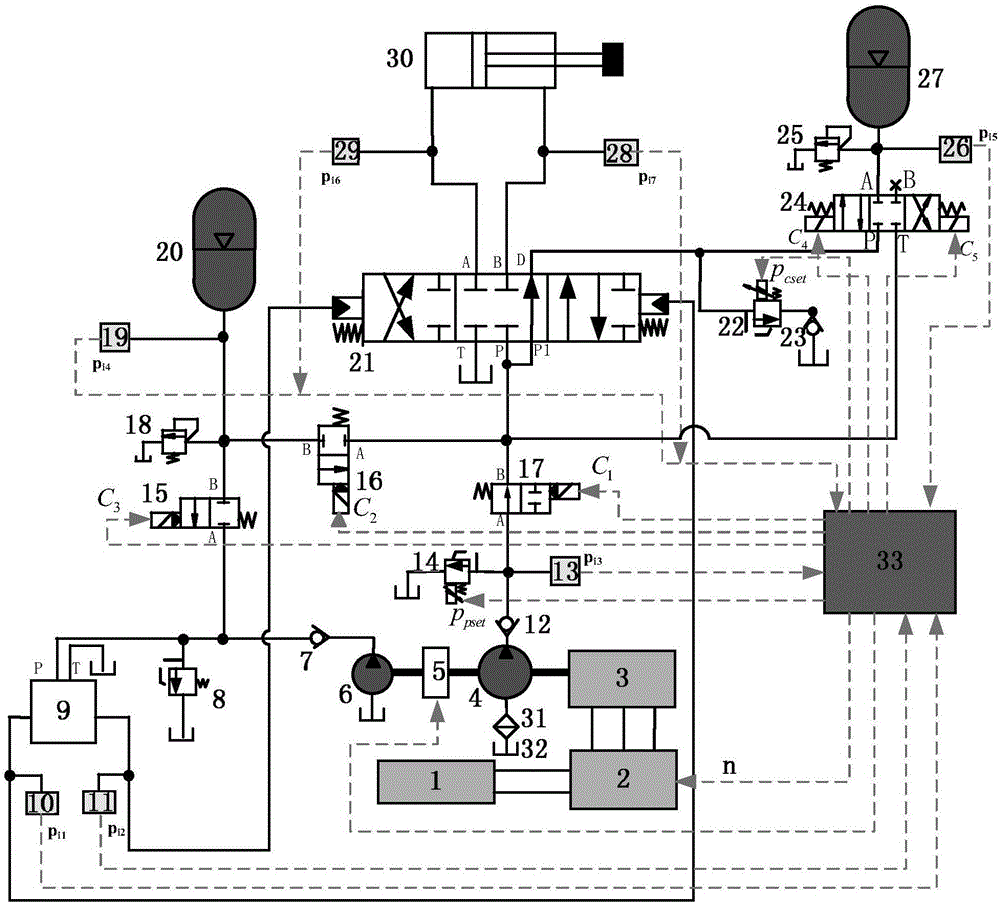

[0050] The present invention provides an automatic idle system based on multi-hydraulic accumulators in order to solve the problems of limited energy saving and poor system controllability existing in the automatic idle speed system of construction machinery in the prior art. The active power drive system uses a variable frequency power motor to drive a quantitative hydraulic pump drive mode, such as figure 1As shown, it includes a power battery 1, a variable frequency power motor (including a frequency converter 2 and a power motor 3), a quantitative hydraulic pump 4, a clutch 5, a pilot pump 6, a first one-way valve 7, a first relief valve 8, a pilot Operating handle 9, first pressure sensor 10, second pressure sensor 11, second one-way valve 12, third pressure sensor 13, first proportional overflow valve 14, first electromagnetic reversing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com