Method for measuring content of suspension in water extract of tobacco raw materials

A determination method and technology of raw water, which are applied in chemical method analysis, chemical analysis by titration method, measuring device, etc., can solve the problems of relatively large fluctuation of components, cumbersome process, long test time, etc., to improve the purity and The effect of high quality, good data reproducibility and short measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

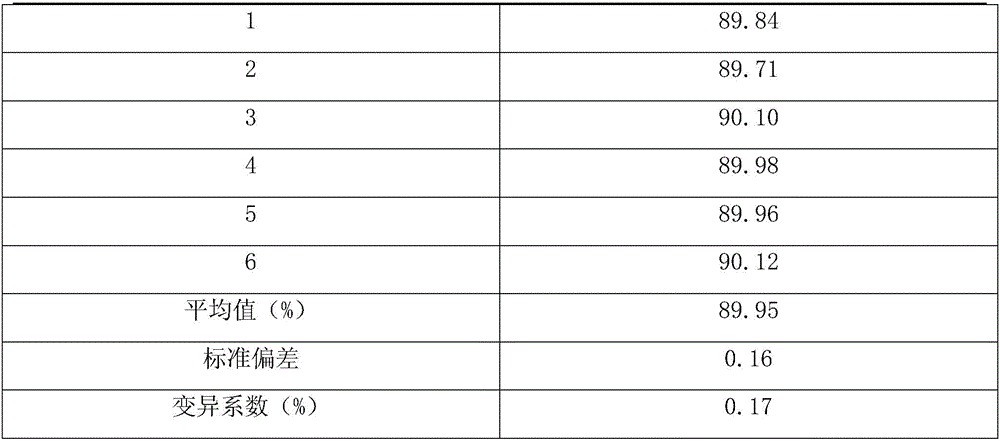

[0016] Example 1 Determination of Suspended Matter Content in Tobacco Stem Water Extract

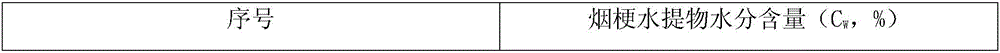

[0017] (1) Sampling 6 times from the extract of the tobacco stem through extraction, solid-liquid separation, and settling agent sedimentation, each sample was divided into 2 parts on average, and one of them was measured by the Karl-Fischer method for the moisture content of the extract (C W , %); Determination result is as following table.

[0018]

[0019]

[0020] (2) adopt the Brix Brix meter to measure the Brix value (S C , %), the results are as follows.

[0021] serial number

Tobacco stem water extract Brix value (S C , %)

1

8.30

2

8.50

3

8.10

4

8.20

5

8.20

6

8.10

average value(%)

8.23

standard deviation

0.15

1.83

[0022] (3) Calculate suspended matter content C in the tobacco raw material water extract SS (%)

[0023] C SS (%)=100-C W ...

Embodiment 2

[0026] Example 2 Determination of Suspended Matter Content in Tobacco Leaf Fragment Water Extract

[0027] (1) Sampling 6 times from the extract of tobacco leaf fragments through extraction, solid-liquid separation, and settling agent sedimentation, each sample was divided into 2 parts on average, and one of them was measured by the Karl-Fischer method for the moisture content of the extract (C W , %); Determination result is as following table.

[0028] serial number

Moisture content of water extract of tobacco leaf shreds (C W , %)

1

89.19

2

89.04

3

88.95

4

89.11

5

89.25

6

89.27

average value(%)

89.14

standard deviation

0.13

0.14

[0029] (2) The Brix value (S C , %), the results are as follows.

[0030]

[0031]

[0032] (3) Calculate suspended matter content C in the tobacco raw material water extract SS (%)

[0033] C SS (%)=100-C...

Embodiment 3

[0035] Example 3 Determination of Suspended Matter Content in Soot Stick Water Extract

[0036] (1) Sampling 6 times from the extraction solution of the cigarette ash rod through crushing, extraction, solid-liquid separation, and settling agent sedimentation, each sample is divided into 2 parts on average, and 1 part adopts the Karl-Fisher method to measure the moisture content of the extract (C W , %); Determination result is as following table.

[0037] serial number

Moisture content of water extract of soot stick (C W , %)

1

88.09

2

88.46

3

88.00

4

87.94

5

87.93

6

88.03

average value(%)

88.08

standard deviation

0.20

0.22

[0038] (2) adopt the Brix Brix meter to measure the Brix value (S C , %), the results are as follows.

[0039] serial number

The Brix value of the water extract of the ash stick (S C , %)

1

6.55

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com