Pretreatment method for pyrolysis analysis of flavor used for extract type tobacco

A technology for tobacco spices and extracts, which is applied in the field of tobacco chemistry, and can solve problems such as the influence of analysis and detection results, low boiling point or retention of heat-sensitive compounds, and achieve the effects of wide application range, convenient quantification, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 of the present invention provides a pretreatment method for analysis of alfalfa extract tobacco spices based on a hot wire pyrolyzer, comprising the following steps:

[0040] (1) Take a certain amount of alfalfa extract to be analyzed and place it in a 15ml flat glass quartz weighing dish, fill the sample with a height of 5mm, and freeze the alfalfa extract in a refrigerator at -50°C for 40 minutes;

[0041] (2) Place the alfalfa extract treated in step (1) in a vacuum freeze dryer with a cold trap temperature of -45°C and a vacuum degree of 250mtorr for 3 hours of vacuum freeze drying;

[0042] (3) Crush the alfalfa extract treated in step (2) into powder, mix well, weigh and fill the sample in the hot wire pyrolyzer.

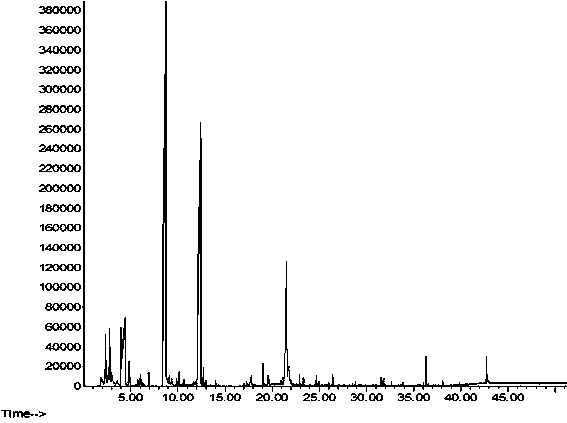

[0043] The powdered alfalfa extract A after the above treatment, the alfalfa extract B after drying at 40-60°C, and the untreated viscous alfalfa extract C were subjected to pyrolysis gas chromatography mass spectrometry analysis test: CDS...

Embodiment 2

[0048] Embodiment 2 of the present invention provides a pretreatment method for the analysis of plum extract tobacco spices based on a hot wire pyrolyzer, comprising the following steps:

[0049] (1) Take a certain amount of sour plum extract to be analyzed and place it in a 15ml flat glass quartz weighing dish. The height of the sample is 4mm, and place the alfalfa extract in a refrigerator at -60°C for 30 minutes;

[0050] (2) Place the sour plum extract treated in step (1) in a vacuum freeze dryer with a cold trap temperature of -50°C and a vacuum degree of 220mtorr for 2 hours of vacuum freeze drying;

[0051] (3) Crush the sour plum extract processed in step (2) into a powder, mix it evenly, weigh it, and fill it with a sample in a hot wire pyrolyzer.

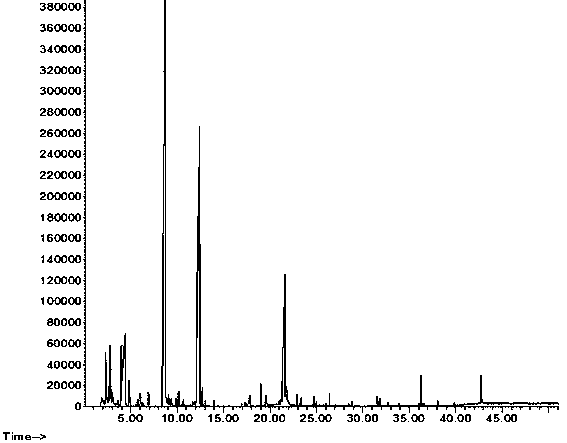

[0052] The powdery sour plum extract sample after the above treatment and the untreated viscous sour plum extract sample were subjected to thermal cracking gas-phase mass spectrometry analysis test: adopt CDS 5200 type the...

Embodiment 3

[0055] Embodiment 3 of the present invention provides a pretreatment method for the analysis of red date extract tobacco spices based on a hot wire pyrolyzer, comprising the following steps:

[0056] (1) Take a certain amount of red jujube extract to be analyzed and put it in a 15ml flat glass quartz weighing dish. The height of the sample is 3mm, and put the alfalfa extract in a refrigerator at -55°C for 35 minutes;

[0057] (2) Place the jujube extract treated in step (1) in a vacuum freeze dryer with a cold trap temperature of -45°C and a vacuum degree of 220mtorr for 1 hour of vacuum freeze drying;

[0058] (3) Crush the jujube extract treated in step (2) into powder, mix well, weigh and fill the sample in the hot wire pyrolysis instrument.

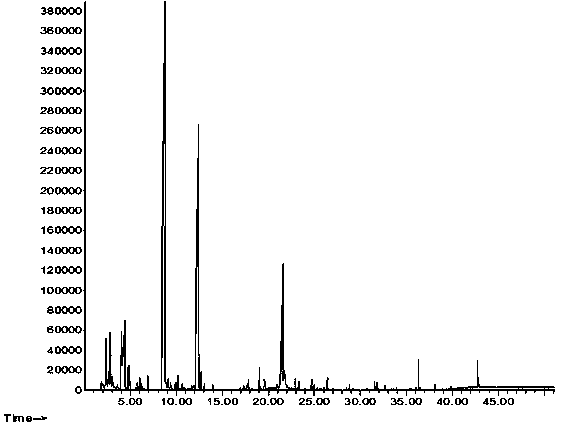

[0059] The above-mentioned treated powdery jujube extract sample and the untreated viscous red jujube extract sample were subjected to thermal cracking gas-phase mass spectrometry analysis test: CDS 5200 thermal cracking instrument wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com