Barrel-shaped solder ball redistribution packaging structure for GSIC (Grand Scale Integration Circuit)

A technology of large-scale integrated circuits and barrel-shaped solder balls, which is applied in the direction of circuits, electrical components, and electrical solid-state devices. It can solve the problems of package thickness and area reduction, and achieve volume reduction, cost saving, and warpage relief. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

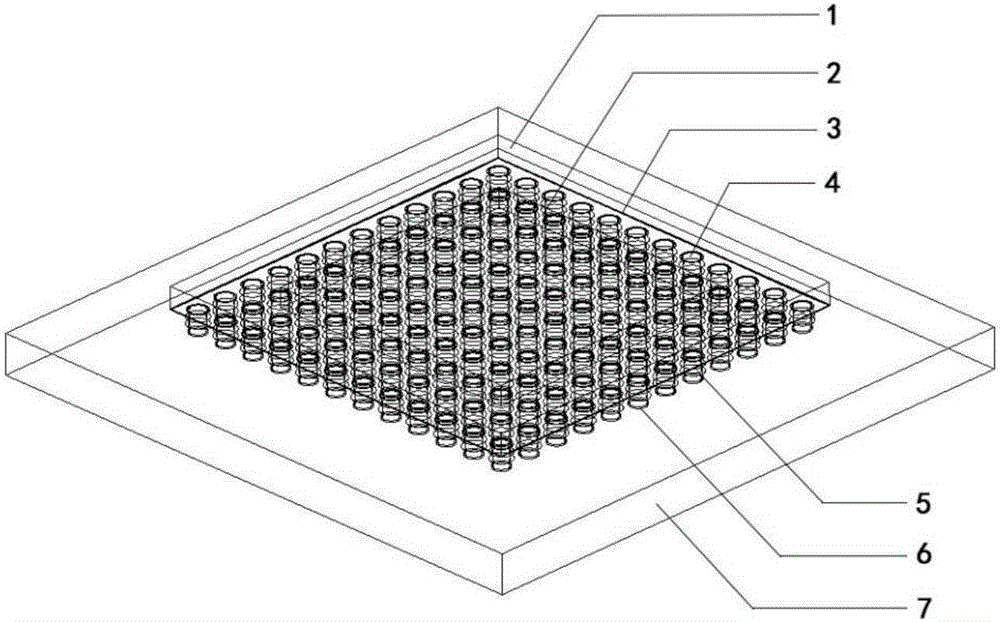

[0017] The process of conventional redistribution packaging technology is as follows: first, place the active surface of the die on the substrate and encapsulate it with epoxy resin; then remove the substrate material; redistribution process, that is, rearrange signal lines, power lines and ground lines ; After implanting spherical solder balls; Finally, the individual chips are cut and opened.

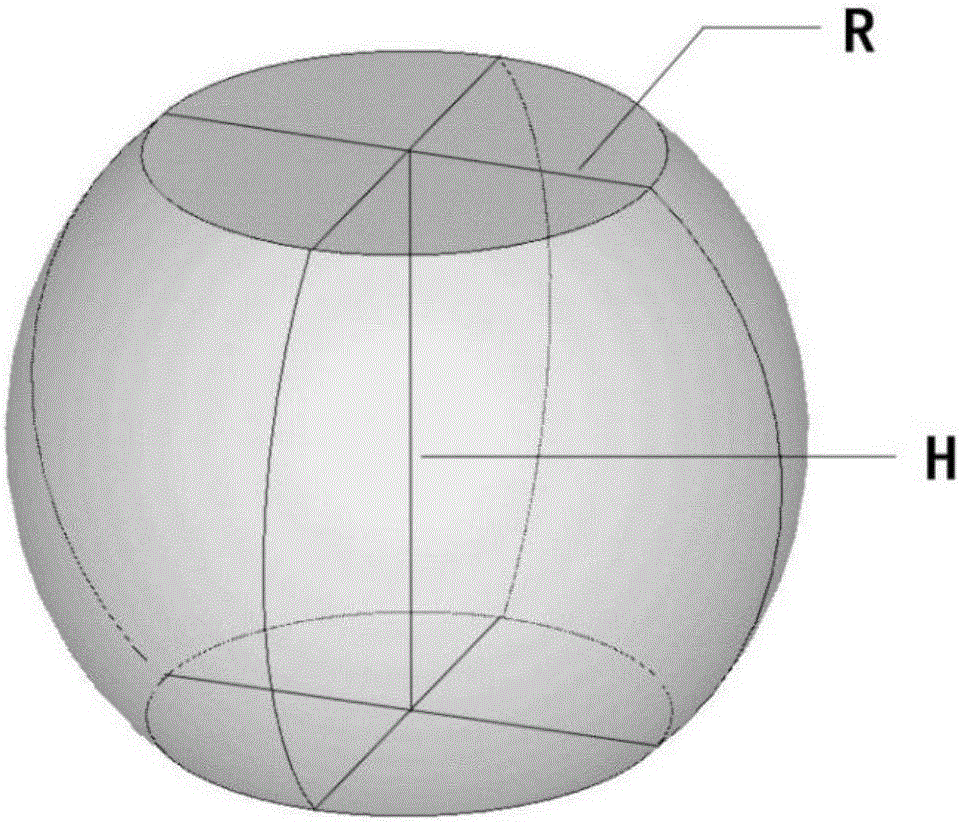

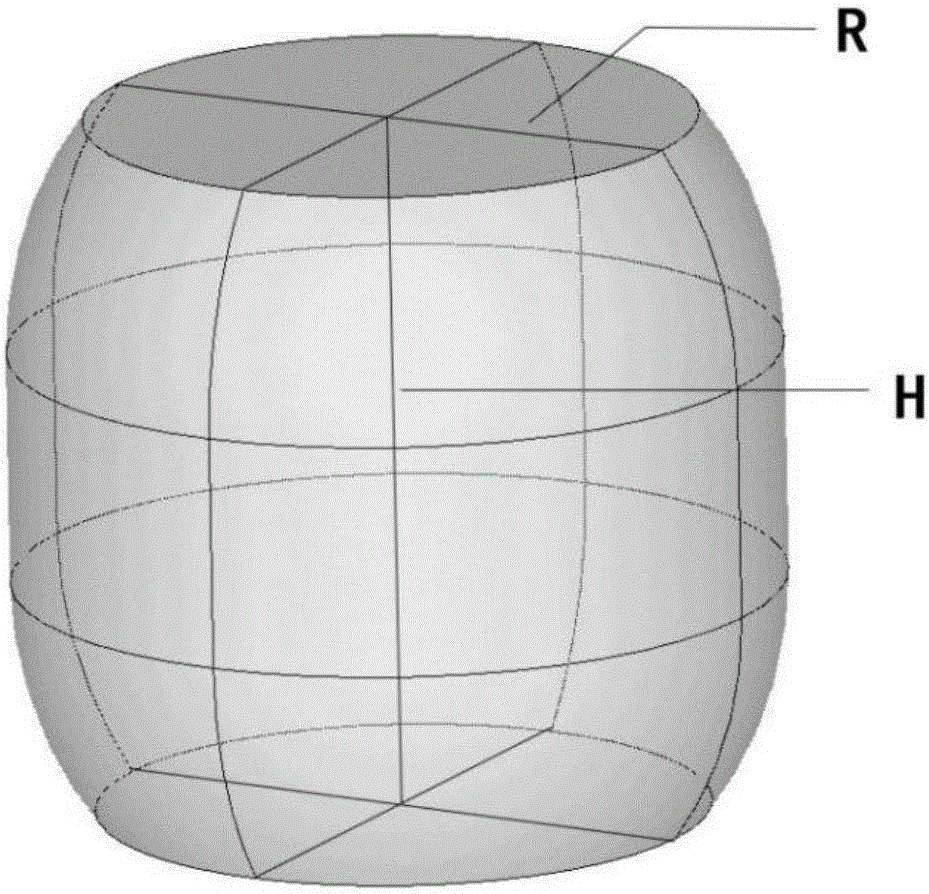

[0018] In order to match the conventional redistribution packaging process, the barrel-shaped solder balls should be designed and produced according to the parameters of the original spherical solder balls, such as the opening of the solder balls, the height of the solder balls, and the material of the solder balls. The upper and lower parts of the barrel-shaped solder ball are two hemispheres, and the solder ball openings at the upper and lower ends must match the original process flow, that is, keep the solder ball opening of the barrel-shaped solder ball consistent with the solder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com