Coated modified lithium ion battery layered cathode material and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems that have not been reported before, achieve uniform coating, ensure electrochemical performance, and improve cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

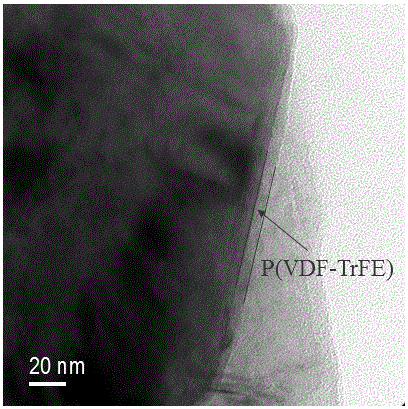

[0029] Add 0.1 g of P(VDF-TrFE) into 5 ml of DEC solution, stir to dissolve; then add 10 g of layered cathode material Li 1.2 [Mn 0.54 Ni 0.13 co 0.13 ]O 2 Add it to the solution after stirring and dissolving, stir again evenly, and dry at 110°C to obtain the coated precursor; place the dried precursor in a tube furnace, heat it in the air, and heat it at 140°C After 3 hours of treatment, the target product coated with 1wt% P(VDF-TrFE) was obtained.

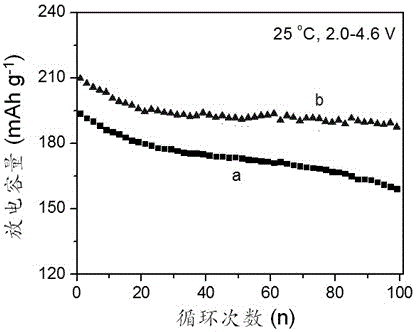

[0030] Such as figure 1 as shown, figure 1 It is the 1wt% P (VDF-TrFE) coated Li of the above-mentioned embodiment 1 1.2 [Mn 0.54 Ni 0.13 co 0.13 ]O 2 / Li button cell cycle performance diagram; where, a is Li 1.2 [Mn 0.54 Ni 0.13 co 0.13 ]O 2 , b is 1wt% P(VDF-TrFE) coated Li 1.2 [Mn 0.54 Ni 0.13 co 0.13 ]O 2 , it can be concluded from the figure that under the same test conditions, the P(VDF-TrFE) coated Li 1.2 [Mn 0.54 Ni 0.13 co 0.13 ]O 2 The cycle performance of the material is significantly improved,...

Embodiment 2

[0033] Add 1 gram of P(VDF-TFE) to 10 ml of EC solution, stir to dissolve; then add 20 grams of layered cathode material Li[Ni 0.6 co 0.2 mn 0.2 ]O 2 Add it to the solution after stirring and dissolving, stir again, and dry at 60°C to obtain the coated precursor; place the dried precursor in a tube furnace, and heat it at 140°C for 3 hours under vacuum conditions. The target product coated with 5wt% P(VDF-TFE) was obtained.

Embodiment 3

[0035] Add 0.1 g of P(VDF-TrFE) to 2 ml of NMP solution, stir to dissolve; then add 20 g of layered cathode material Li[Ni 0.5 co 0.2 mn 0.3 ]O 2 Add it to the solution after stirring and dissolving, stir again, and dry at 60°C to obtain the coated precursor; place the dried precursor in a tube furnace, and heat it at 140°C for 3 hours in the air environment , the target product coated with 0.5wt% P(VDF-TrFE) was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com