Phosphor, light emitting element, and light emitting device

A technology for light-emitting elements and phosphors, applied in the field of phosphors, can solve problems such as difficulty in achieving high brightness, and achieve the effects of high color rendering and color reproducibility, excellent moisture resistance, and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3 and comparative example 1

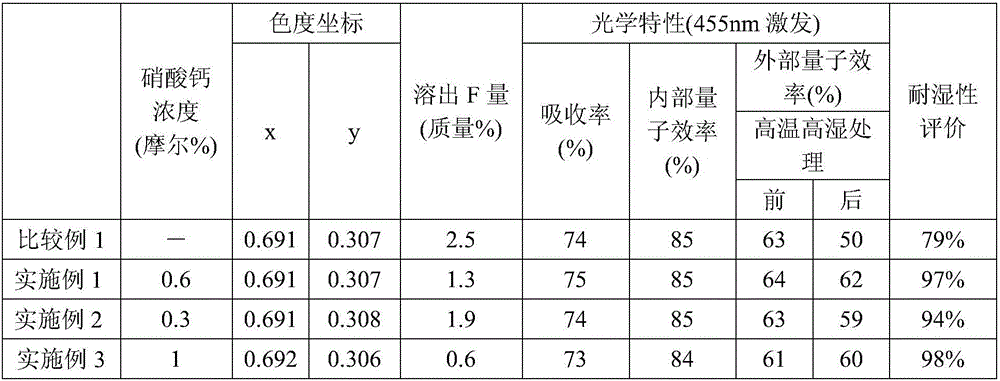

[0059] Examples 1 to 3 and Comparative Example 1 all involve the general formula: A 2 MF 6 : Mn 4+ Indicates the phosphor whose element A is K, element M is Si, F is fluorine, and Mn is manganese. 2 SiF 6 : Mn 4+ Represents the phosphor. Comparative Example 1 is a conventional phosphor that does not contain a Ca-containing compound on the surface of the particles, and Examples 1 to 3 are phosphors that contain a Ca-containing compound on the surface of the particles and are surface-modified.

[0060]

[0061] At room temperature, 500 ml of hydrofluoric acid with a concentration of 48% by mass was put into a beaker made of Teflon (registered trademark) with a capacity of 1 liter, and K 2 SiF 6 Powder (manufactured by Wako Pure Chemical Industries, Ltd., grade: for chemical use) 50g and K synthesized by the aforementioned method 2 MnF 6 Powder 5g, prepare suspension.

[0062] A beaker made of Teflon (registered trademark) containing the suspension was placed on a hot plate and heated ...

Embodiment 2 and 3

[0068] In Examples 2 and 3, the method and conditions were exactly the same as in Example 1, except that the concentration of the calcium nitrate aqueous solution added to the phosphor suspension was changed to 0.3 mol% and 1 mol%, respectively.

[0069]

[0070] Next, the obtained phosphor was evaluated by the following method.

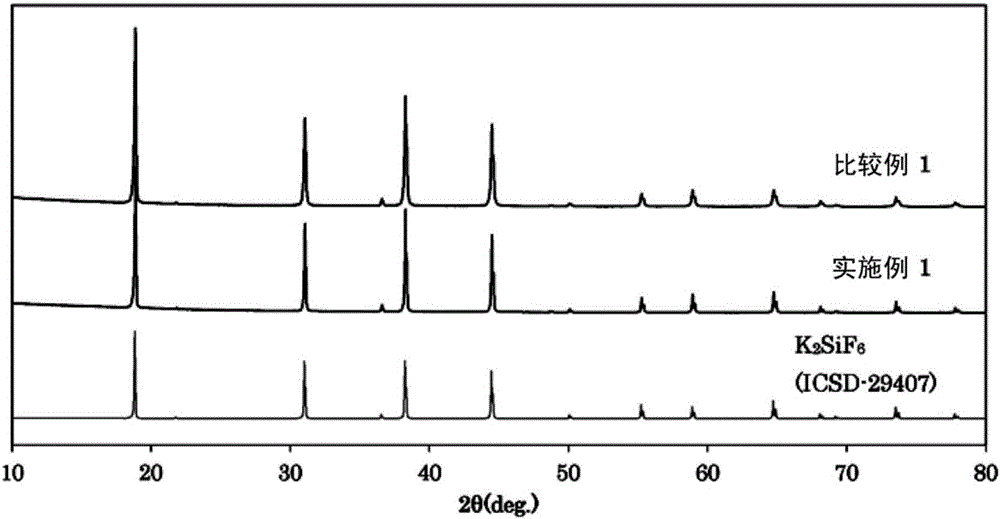

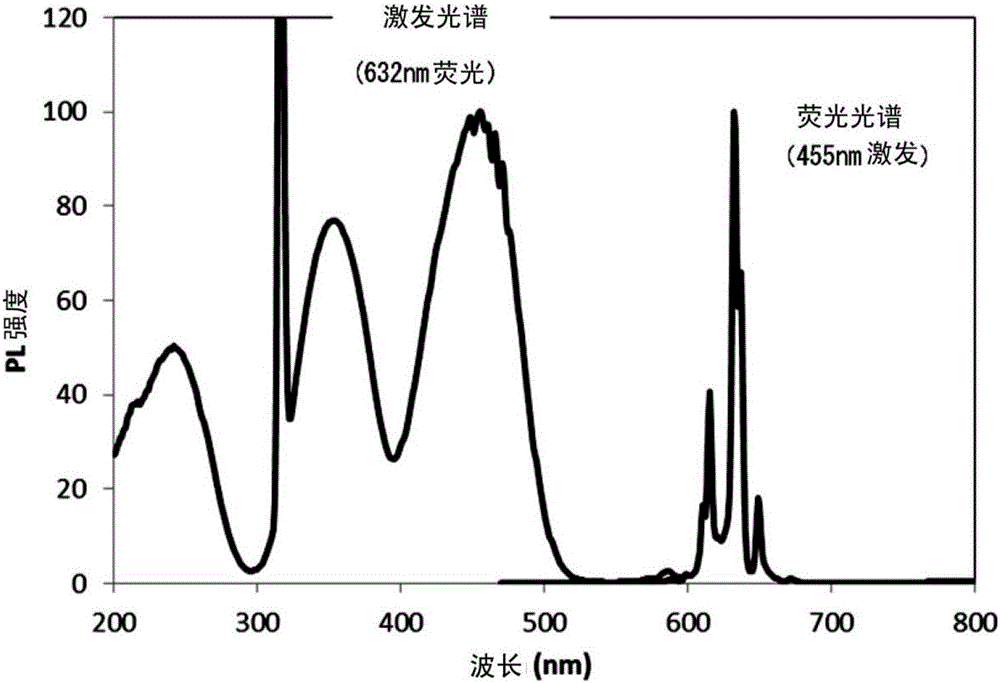

[0071] First, for the phosphors of Comparative Example 1 and Examples 1 to 3, the crystal phase, excitation spectrum / fluorescence spectrum, quantum efficiency, chromaticity coordinates, eluted F amount, and moisture resistance were evaluated. The evaluation results are shown in Table 1 and Figure 1~2 .

[0072] [Table 1]

[0073]

[0074]

[0075] The X-ray diffraction pattern of the phosphor was measured using an X-ray diffraction apparatus (Ultima IV manufactured by Rigaku Corporation). CuKα tube was used for the measurement.

Embodiment 4

[0098] A light-emitting element having the phosphor of Example 1 and a cyan light-emitting LED as a light-emitting source was produced. Since this light-emitting element uses the phosphor of Example 1 which is excellent in moisture resistance, it is excellent in color rendering and color reproducibility. In addition, compared with the light-emitting element using the phosphor of Comparative Example 1, the brightness reduction caused by the passage of time is less.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com