A kind of difenoconazole dispersible oil suspension concentrate and its preparation method and application

A technology of difenoconazole and dispersing oil, which is applied in the direction of botanical equipment and methods, applications, biocides, etc., and can solve the problem that the anti-rainwater erosion ability has not been well effected, restricts efficient, safe and scientific use, Target crops with poor wetting and deposition properties, etc., to achieve the effect of reducing the loss of pesticides, improving deposition and retention efficiency, and improving effective utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

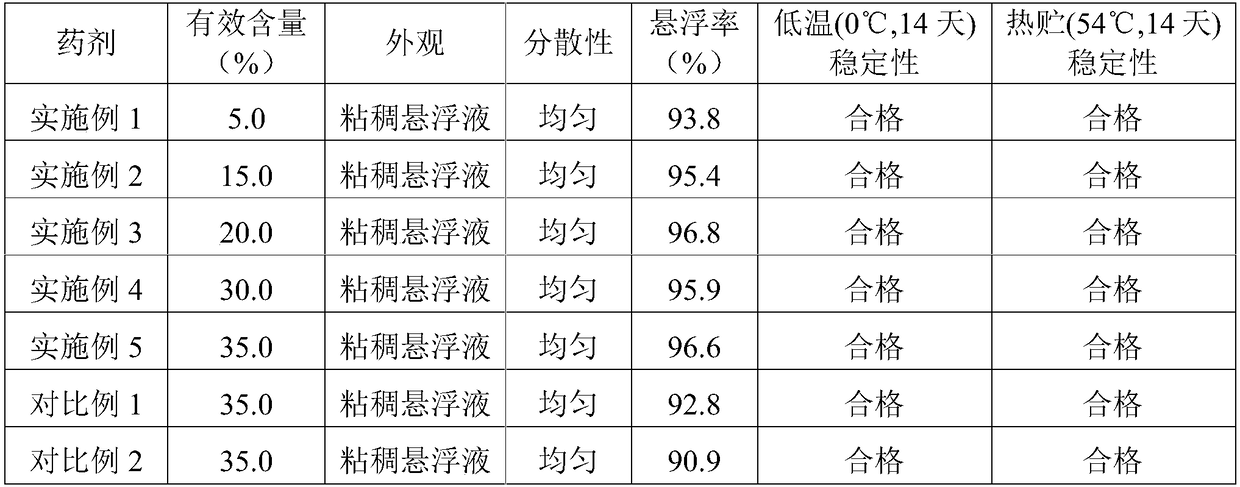

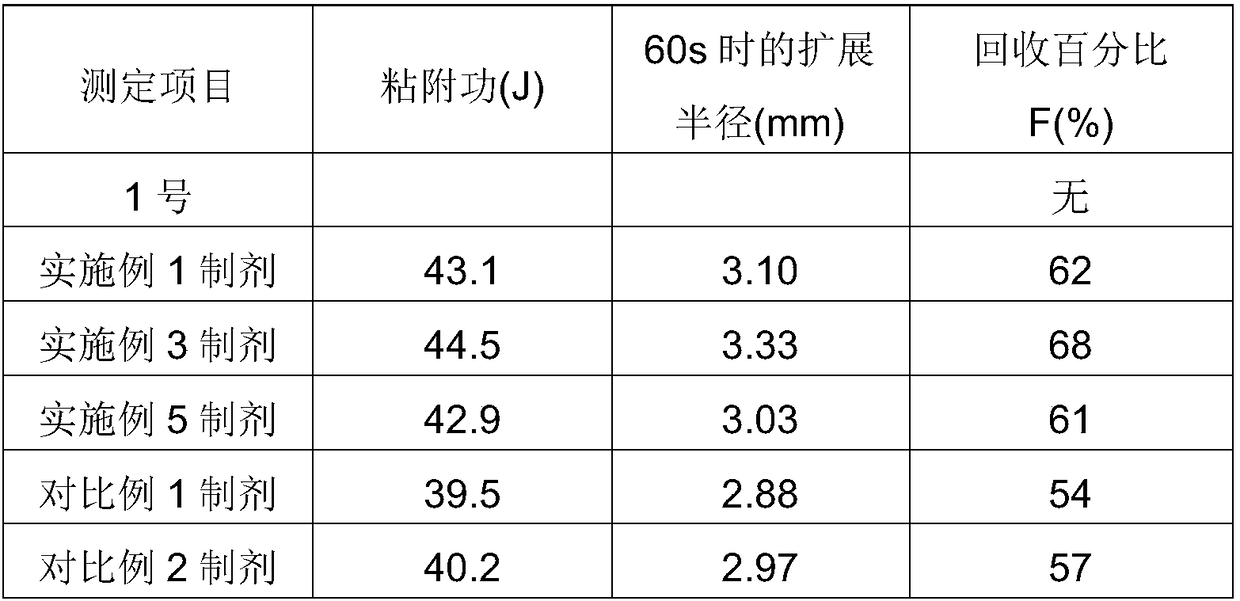

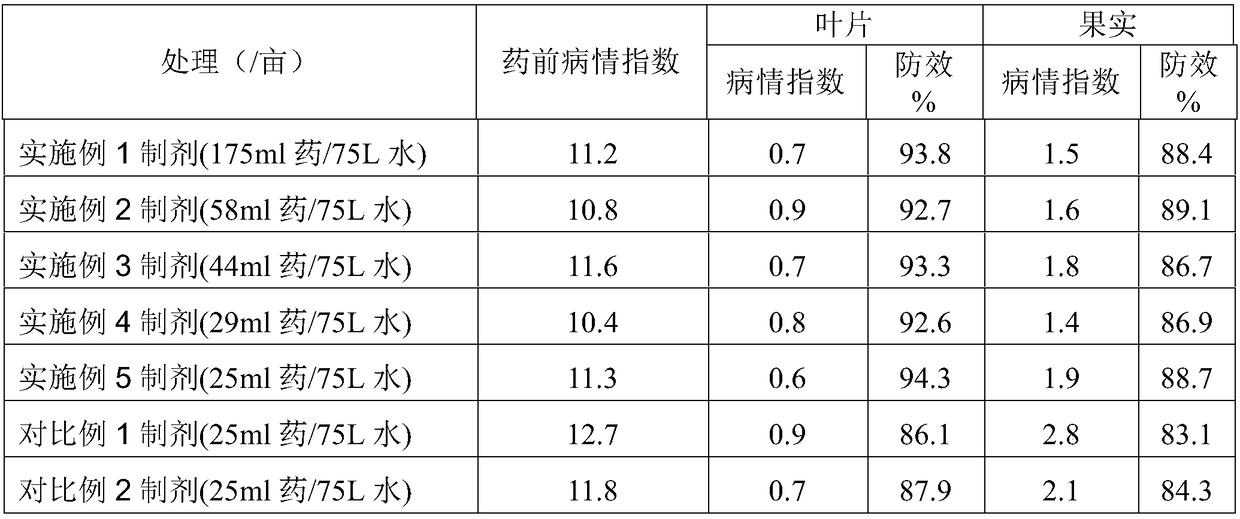

Examples

Embodiment 1

[0026] In a 1500 ml glass jar, add 777.4 grams of a 2:1 mixture of pine resin-based vegetable oil and methylated vegetable oil, dibenzyl biphenyl polyoxyethylene ether + styrylphenyl polyoxyethylene ether + triphenyl Ethylphenol polyoxypropylene polyoxyethylene block polymer 5:4:4 mixture 50 grams, alkyl sulfate and phosphoric acid ester 1:1 mixture 10 grams, isopropanol 40 grams, stir and mix evenly; add purity It is 52.9 grams of 95% difenoconazole technical material and 80 grams of fumed white carbon black. After stirring and mixing, shear at high speed (6000-8000r / min) for 5 minutes, and then enter the sand mill for grinding. When the main technical indicators meet the standard requirements After that, 5% difenoconazole dispersible oil suspension concentrate was obtained.

Embodiment 2

[0028] In a 1500 ml glass flask, add 662.1 grams of turpentine-based vegetable oil, dibenzyl biphenyl polyoxyethylene ether + styrylphenyl polyoxyethylene ether + triphenylethylphenol polyoxypropylene polyoxyethylene embedded 70 grams of a 5:4:4 mixture of segmented polymers, 20 grams of a 1:1 mixture of alkyl sulfates and phosphates, and 30 grams of octanol, stir and mix well; then add 157.9 grams of difenoconazole with a purity of 95% gram, 60 grams of diatomaceous earth, after stirring and mixing, shear at high speed (6000-8000r / min) for 5 minutes, and then enter the sand mill for grinding. When the main technical indicators meet the standard requirements, 15% difenoconazole dispersible oil suspension.

Embodiment 3

[0030] In a 1500ml glass flask, add 609.5g of a 2:1 mixture of turpentine-based vegetable oil and methylated vegetable oil, dibenzyl biphenyl polyoxyethylene ether + styrylphenyl polyoxyethylene ether + triphenylethyl ether 70 grams of a 5:4:4 mixture of phenol-polyoxypropylene-polyoxyethylene block polymers, 30 grams of a 1:1 mixture of alkyl sulfates and phosphate esters, 40 grams of a 2:1 mixture of isopropanol and octanol, and stir Mix evenly; then add 210.5 grams of difenoconazole technical material with a purity of 95%, 40 grams of a 1:3 mixture of fumed silica and diatomaceous earth, stir and mix, and shear at high speed (6000-8000r / min) for 5 minutes. Then it enters into a sand mill for grinding, and when the main technical indicators meet the standard requirements, a 20% difenoconazole dispersible oil suspension concentrate is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com