Potato angelica keiskei composite noodle and making method thereof

A production method and noodle technology, which are applied in the food field, can solve the problems of limiting the amount of potato whole flour added, difficulty in highlighting the nutritional value of noodles, and high price, and achieve the effects of improving nutritional value and flavor, good toughness and good taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

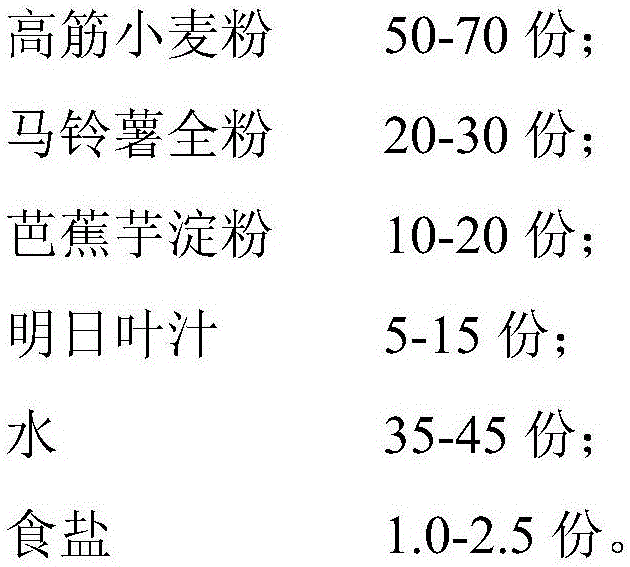

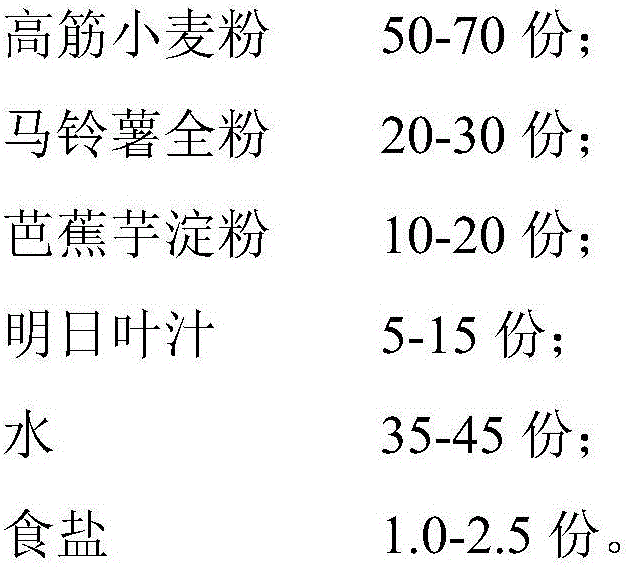

[0031] Ingredients: 60 kg of high-gluten wheat flour, 30 kg of whole potato flour, 10 kg of plantain taro starch, 10 kg of Ashitaba juice, 40 kg of water and 2 kg of salt.

[0032] Production Method:

[0033] Mix high-gluten wheat flour, whole potato flour, plantain taro starch, and Ashitaba juice into a mixture, and dissolve the salt in the water into salt water;

[0034] Slowly pour the salt water into the mixture in portions, stirring while adding, and then perform the first kneading, that is, repeatedly flatten the dough and stack it in the same direction, and repeat this many times.

[0035] Cover with plastic wrap and let for 30 minutes;

[0036] Brush the oil on the surface of the proofed dough, and knead the dough for the second time, that is, repeatedly flatten the dough and stack it in the same direction, and repeat this many times, and beat the dough;

[0037] Sprinkle dry flour on the chopping board and roll the dough, that is, sprinkle a little flour on the surface of the do...

Embodiment 2

[0043] Ingredients: 50 kg of high-gluten wheat flour, 30 kg of whole potato flour, 20 kg of plantain starch, 5 kg of Ashitaba juice, 45 kg of water and 1.5 kg of salt.

[0044] The production method is the same as in Example 1.

Embodiment 3

[0046] Ingredients: 70 kg of high-gluten wheat flour, 20 kg of potato flour, 10 kg of plantain starch, 15 kg of Ashitaba juice, 35 kg of water and 2.5 kg of salt.

[0047] The production method is the same as in Example 1.

[0048] The noodle quality indicators obtained in the three examples are shown in Table 1, and the sensory evaluation results are shown in Table 2:

[0049] Table 1

[0050]

[0051] Table 2 (10 points for each indicator)

[0052]

[0053] The potato Ashitaba composite noodles of the present invention have the unique flavor of potato, uniform structure, and delicate taste; and have the emerald green color and fragrance of Ashitaba. It is rich in vitamins, mineral elements, dietary fiber, amino acids, chalcone functional ingredients, organic germanium and other substances, with balanced and comprehensive nutrition, high nutritional value and certain health benefits; the production process raw materials are easy to obtain, and the operation is simple It is suit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com