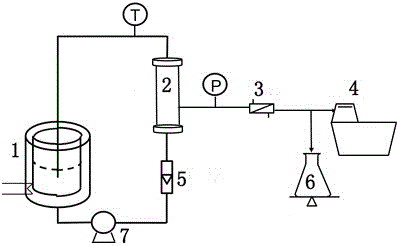

Membrane distillation desalination method and apparatus thereof

A desalination device and membrane distillation technology, applied in the field of separation process, can solve problems such as hydrophilization leakage, membrane material resistance to high temperature, pollution, etc., and achieve the effects of prolonging service life, good hydrophobic performance, and large membrane area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

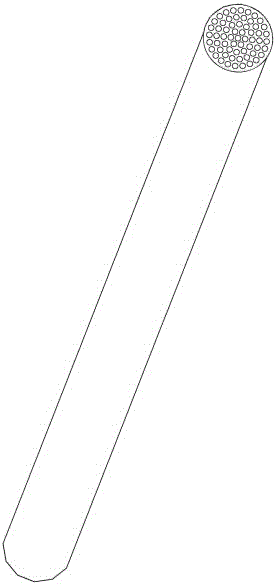

[0041] (1) The 19-channel ceramic membrane material is hydrophobically modified by surface grafting modification. Fully stir evenly at 35°C and normal pressure. After the modification solution was reacted for 5 h, the ceramic membrane was placed in the prepared modification solution and vacuumized. After the reaction was complete and no air bubbles were generated on the surface, the ceramic membrane was washed three times with deionized water and ethanol, placed in an oven, and dried at 120 °C for 4 h to obtain a ceramic membrane with good hydrophobic properties.

[0042] (2) Prepare a brine solution with a concentration of 35 g / L and pour it into the raw material tank of membrane distillation for heating;

[0043] (3) After reaching the set 75°C, turn on the feed liquid pump, and turn on the vacuum pump after the system temperature is stable, and set the vacuum degree to 0.095 MPa;

[0044] (4) The membrane distillation system starts to work, the feed liquid flow rate is 16...

Embodiment 2

[0048] (1) The 37-channel ceramic membrane material is hydrophobically modified by surface grafting modification. Stir fully and evenly at 50°C and normal pressure. After the modification solution was reacted for 12 h, the ceramic membrane was placed in the prepared modification solution and vacuumized. After the reaction was complete and no air bubbles were generated on the surface, the ceramic membrane was washed three times with deionized water and ethanol, placed in an oven, and dried at 120 °C for 4 h to obtain a ceramic membrane with good hydrophobic properties.

[0049] (2) Prepare a brine solution with a concentration of 200 g / L and pour it into the raw material tank of membrane distillation for heating;

[0050] (3) After reaching the set 55°C, turn on the feed liquid pump, and turn on the vacuum pump after the system temperature is stable, and set the vacuum degree to 0.085 MPa;

[0051] (4) The membrane distillation system starts to work, the feed liquid flow rate...

Embodiment 3

[0055] (1) The 61-channel ceramic membrane material is hydrophobically modified by surface grafting modification. Fully stir evenly at 70°C and normal pressure. After the modification solution was reacted for 2 h, the ceramic membrane was placed in the prepared modification solution and vacuumized. After the reaction was complete and no air bubbles were generated on the surface, the ceramic membrane was washed three times with deionized water and ethanol, placed in an oven, and dried at 120 °C for 4 h to obtain a ceramic membrane with good hydrophobic properties.

[0056] (2) Prepare a brine solution with a concentration of 120 g / L, pour it into the raw material tank of membrane distillation for heating;

[0057] (3) After reaching the set 70°C, turn on the feed liquid pump, and turn on the vacuum pump after the system temperature is stable, and set the vacuum degree to 0.095 MPa;

[0058] (4) The membrane distillation system starts to work, the feed liquid flow rate is 40 L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com