Preparation method of a novel w‑mo‑cr alloy polishing disc

A polishing disc and alloy technology, which is applied in the preparation of alloy polishing disc materials and the preparation of high-hardness alloy materials, can solve the problems of uneven sintering, poor high-temperature oxidation resistance, incomplete solid solution of alloys, etc., and achieve low surface roughness , High-temperature oxidation resistance is good, and the effect of preparation is strong and repeatable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

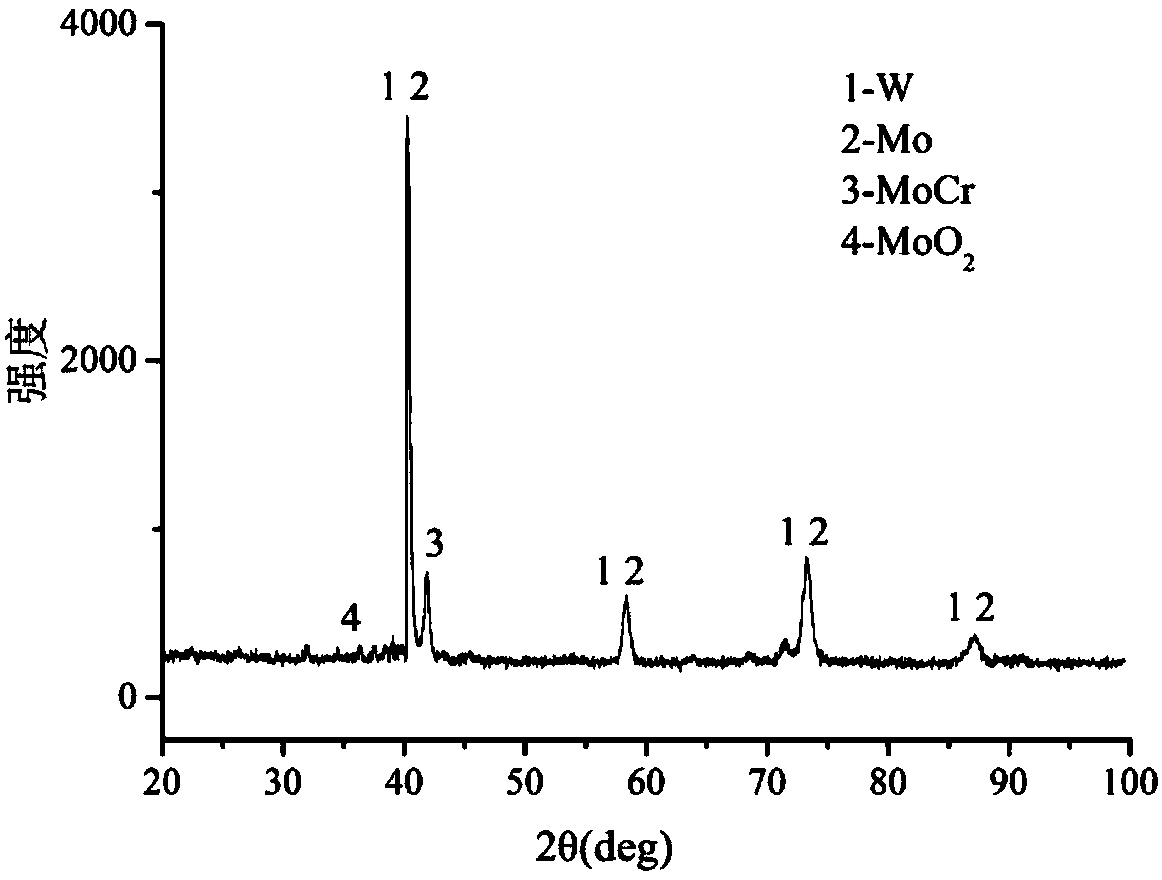

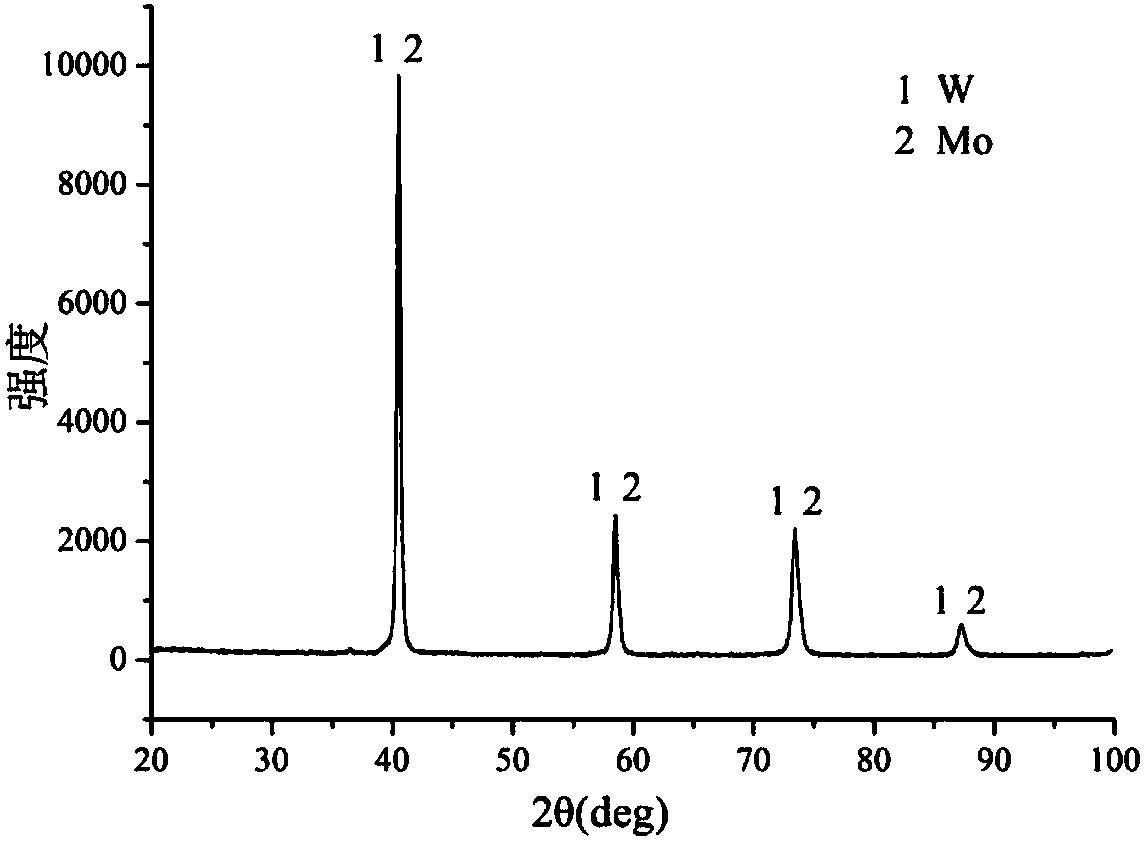

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. The present invention starts from the mechanism of transition metal catalyzed diamond graphitization, and combines the performance requirements of the polishing disc material for tribochemical polishing, invents a new type of W-Mo-Cr alloy polishing disc, and selects four kinds of W, Mo, Cr and Y The powder is used as the raw material for the preparation of the alloy polishing disk, and the new alloy polishing disk is made by ball milling with a high-energy ball mill and vacuum hot-pressing sintering. Specifically include the following steps:

[0022] 1) Determining the composition ratio of the alloy polishing disc: Four powders of W, Mo, Cr and Y are used, each powder has a purity of 99.9% and a particle size of 300 mesh. First, W, Mo, and Cr are weighed according to the molar ratio of 72%:27%:1%. Weigh 49.88g of tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com