Method for forming structural-color metal surface based on blazed grating structure through tool cutting

A blazing grating and metal surface technology, applied in the field of metal surface finishing, can solve the problems of large flow resistance, weak corrosion resistance, no structural color, etc., and achieve low fluid flow resistance, strong corrosion resistance, and good hydrophobicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with and embodiment the present invention is further described.

[0017] A method for tool cutting and forming a structural color metal surface based on a blazed grating structure, comprising the following steps:

[0018] (1) Smooth the surface of the metal workpiece so that the surface roughness does not exceed 100nm;

[0019] (2) cutting a set parallel groove group on the surface of the metal workpiece according to the set process parameters with the tool;

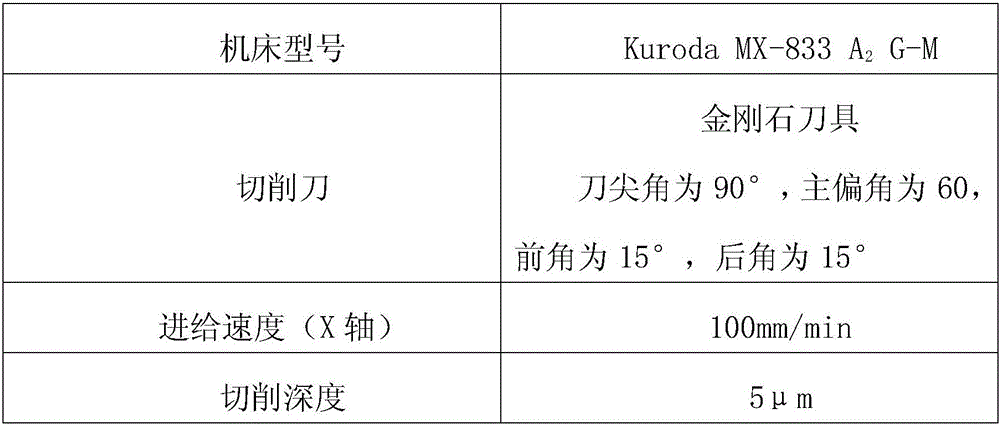

[0020] The processing object of the inventive method is a metal workpiece made of a viscous metal material (such as copper, titanium alloy, etc.); the cutting related process parameters in the step (2) of the inventive method are as follows: the cutting tool nose angle is selected to be 80°~100° °, the main declination angle is 50°~65°, the rake angle is 10°~20°, and the rear angle is 10°~20°; when cutting, the angle between the tool and the workpiece surface is 5°~30°, The feeding speed is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com