A cutting machine tool for preparing bone samples

A technology for cutting machine tools and samples, which is applied in the field of micro-cutting machine tools for preparing small samples of biological bones, which can solve the problems of time-consuming and labor-intensive reduction of processing accuracy, and achieve the effects of uniform thickness, reduced types, and avoiding dehydration or excessive absorption of cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The following will combine Figure 1 to Figure 6 The specific technical solutions of the present invention are described in detail.

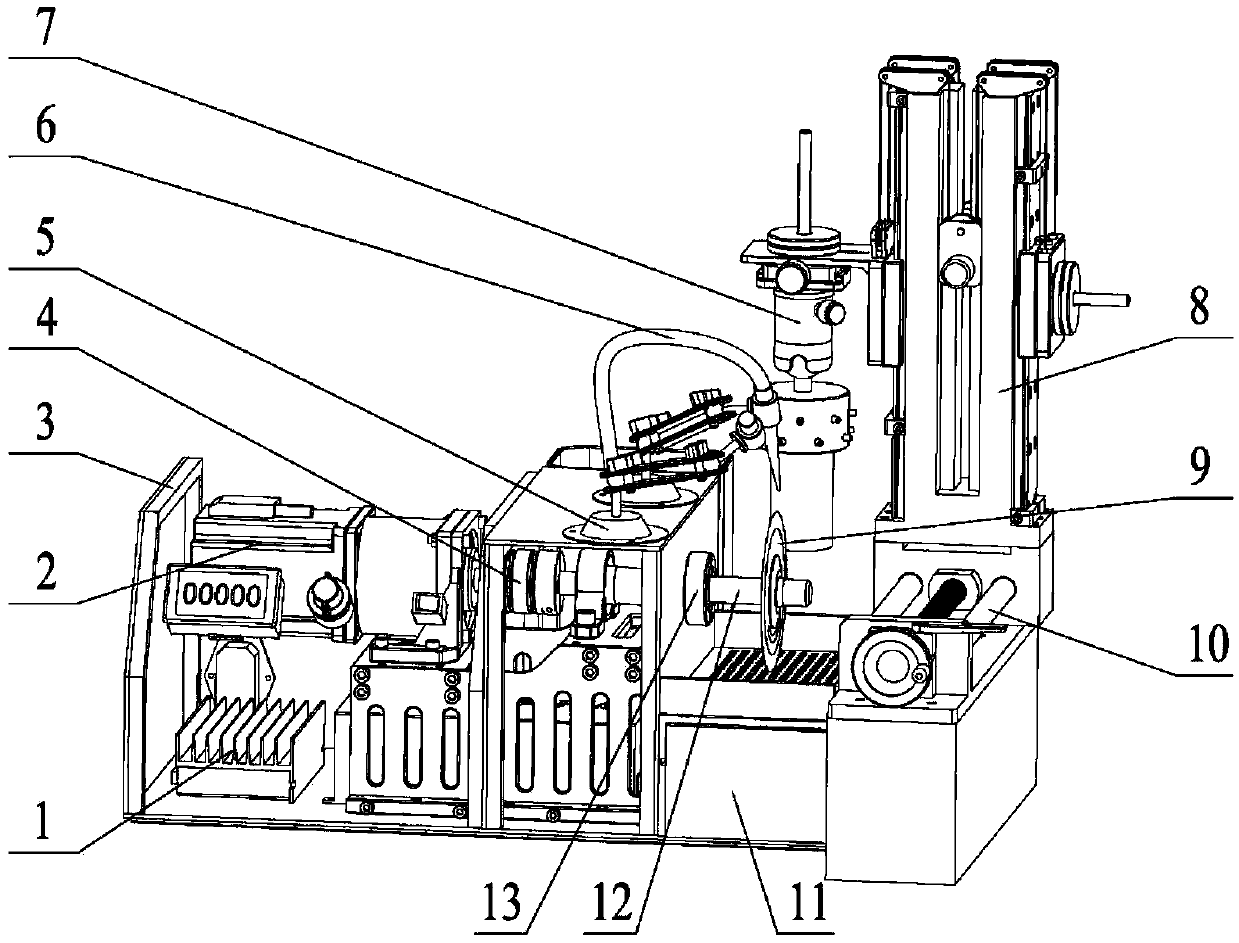

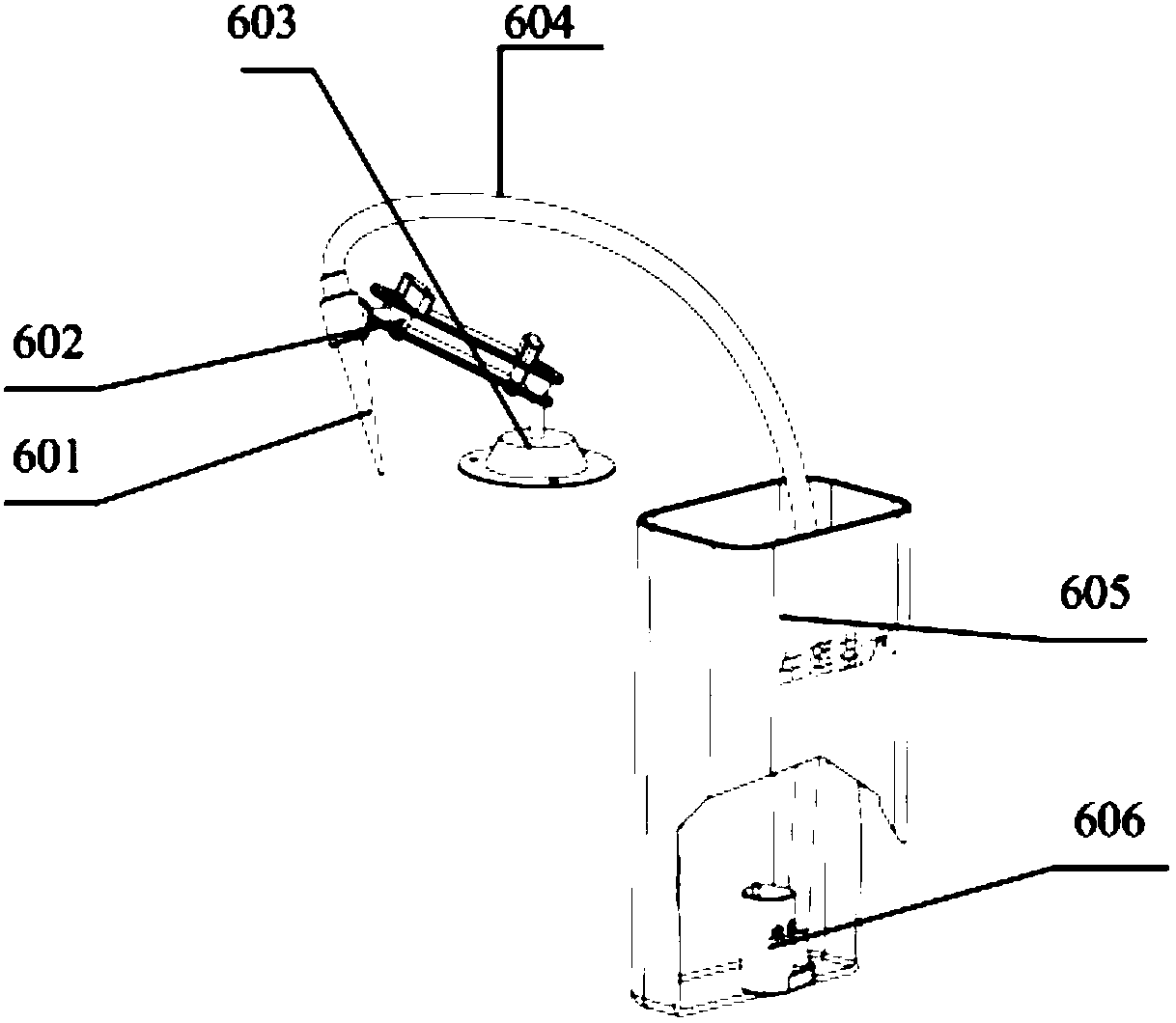

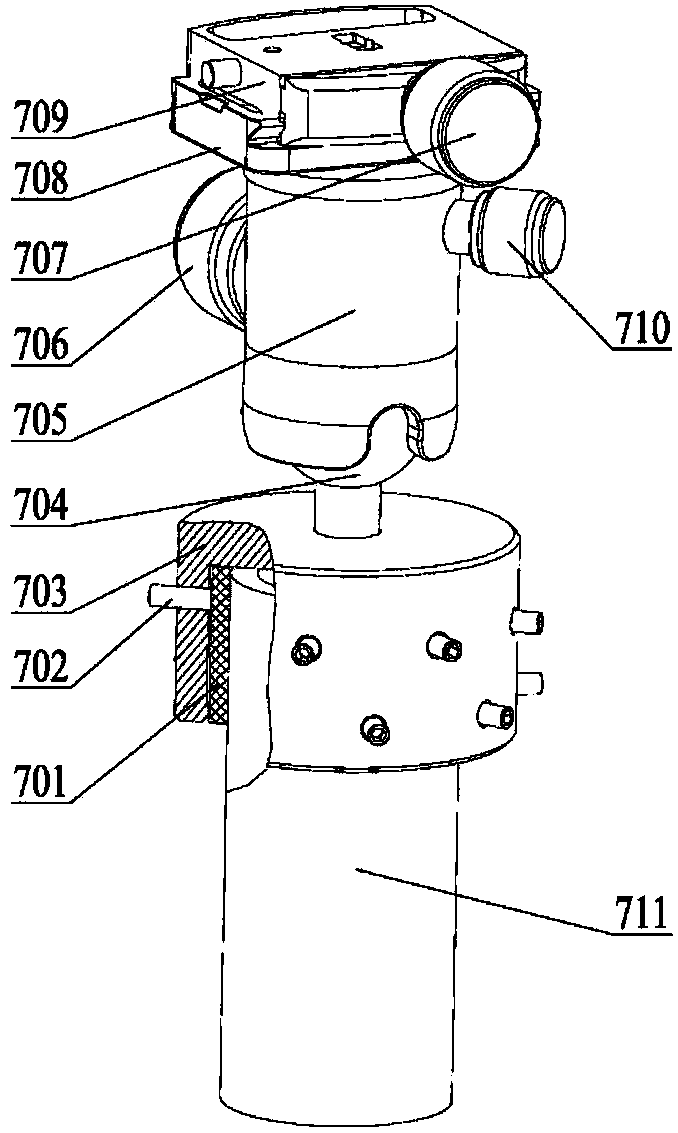

[0078] Such as figure 1 As shown, a cutting machine tool for preparing bone samples, including a motor driver 1, a motor 2, a chassis 3, a coupling 4, a laser collimator 5, a hydraulic cooling system 6, a multi-angle adjustable pan-tilt assembly 7, Lifting column assembly 8, cutting saw blade 9, feed guide rail assembly 10, residual hopper assembly 11, transmission shaft 12.

[0079] The motor driver 1, motor 2 and coupling 4 are packaged in a chassis 3 constructed of aluminum profiles. At the same time, the chassis 3 is equipped with a fan to dissipate heat from the motor, and the residual hopper assembly 11 is installed by fastening screws. The residual hopper assembly The cutting saw blade 9 driven by the transmission shaft 12 is installed above the 11 to cut the bone sample 711 clamped on the multi-angle adjustment pan-tilt assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com