Permanent-magnetic direct-drive type open mill

A permanent magnet direct drive, open mill technology, applied in the field of open mills, can solve the problems of low degree of automatic control, low drive system efficiency, and many transmission links, etc., to reduce labor costs, good startup performance, and fast response. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

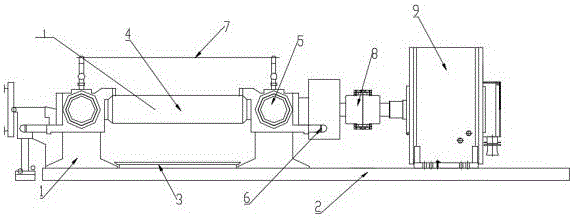

[0013] see figure 1 , a permanent magnet direct drive mill, comprising a frame 1, a base 2, a material receiving tray 3, a roller 4, a pitch adjustment device 5, a speed ratio gear 6, an emergency shutdown device 7, a low-speed coupling 8 and Direct drive permanent magnet synchronous motor 9, the frame 1, material receiving tray 3, roller 4, pitch adjustment device 5, speed ratio gear 6, emergency shutdown device 7, low speed coupling 8 and direct drive permanent magnet synchronous motor 9 are all installed on the upper end of the base 2, the number of the frame 1 is two and the two frames 1 are connected by the roller 4, the receiving tray 3 is located directly below the roller 4, and each frame 1 is installed There is a distance adjustment device 5, and the emergency shutdown device 7 is located behind the roller 4. The speed ratio gear 6 is ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com