A kind of preparation method of flower-shaped copper sulfide-nitrogen methyl pyrrolidone dispersant

The technology of nitrogen methyl pyrrolidone and polyvinyl pyrrolidone is applied in the field of preparation of flower-shaped copper sulfide-nitrogen methyl pyrrolidone dispersant, which can solve problems such as difficulty in preparing uniformly dispersed polymer/copper sulfide film, and achieves low material price , the preparation is simple, the effect of improving the photothermal conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) First weigh 0.5g polyvinylpyrrolidone, add 15mL nitrogen methylpyrrolidone to dissolve and disperse, wait until the solution becomes clear and transparent, add 0.5mmoL copper sulfate pentahydrate solid under magnetic stirring, and continue stirring for 20 minutes to obtain a bright green color clear solution;

[0029] (2) Weigh 1mmoL of sulfur powder in the lining of a 25mL polytetrafluoroethylene reactor, then pour the above solution into the lining and stir for 10 minutes;

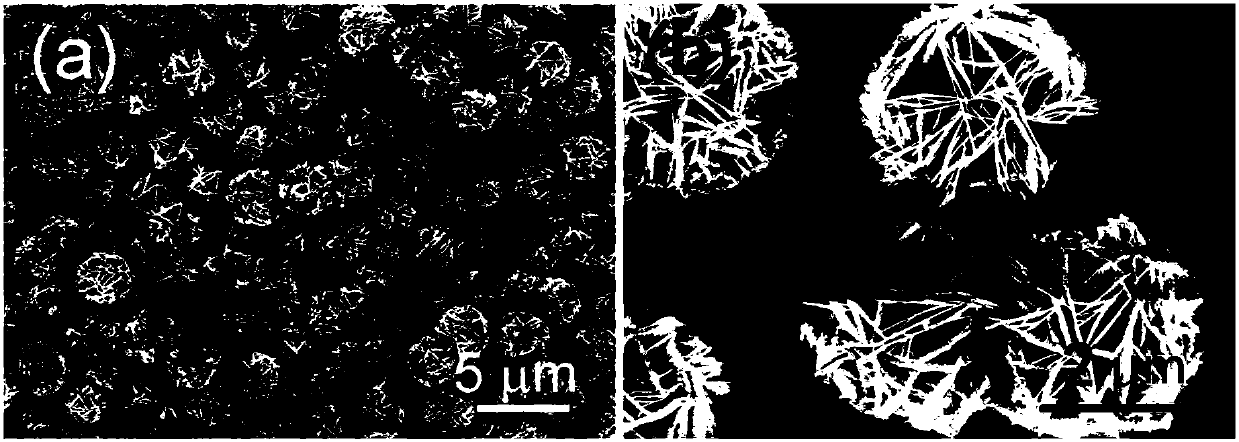

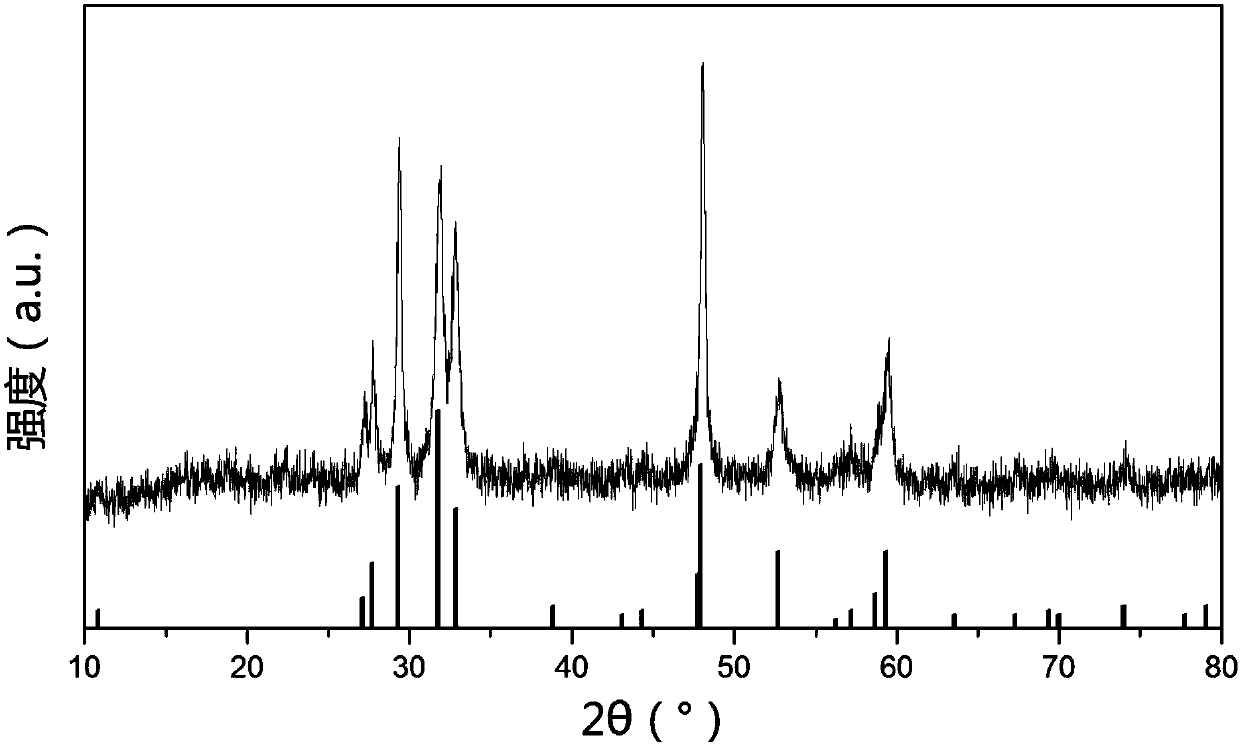

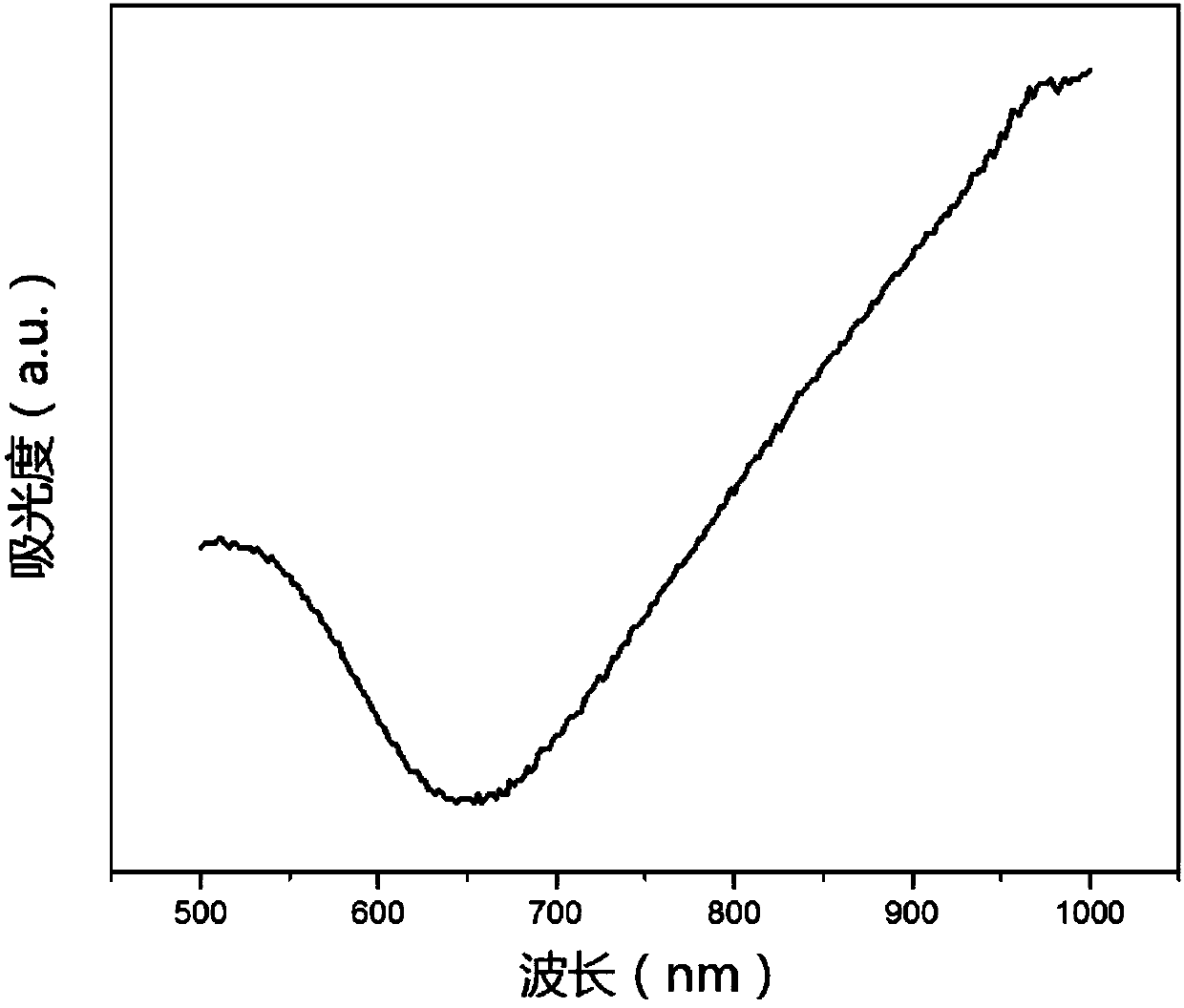

[0030] (3) Assemble the reaction kettle and react at 180° C. for 4 hours. After the reaction, pour off the supernatant, purify by centrifugation, and redisperse in nitrogen methyl pyrrolidone to prepare copper sulfide-nitromethyl pyrrolidone dispersant. The low magnification SEM collection of illustrative plates (a) and the high magnification SEM collection of illustrative plates (b) of copper sulfide sample in this copper sulfide-nitromethylpyrrolidone dispersant are as figure 1 Shown, the ...

Embodiment 2

[0033] (1) First weigh 0.5g polyvinylpyrrolidone, add 15mL nitrogen methylpyrrolidone to dissolve and disperse, wait until the solution becomes clear and transparent, add 0.5mmoL copper sulfate pentahydrate solid under magnetic stirring, and continue stirring for 20 minutes to obtain a bright green color clear solution;

[0034] (2) Weigh 1mmoL of sulfur powder in the lining of a 25mL polytetrafluoroethylene reactor, then pour the above solution into the lining and stir for 10 minutes;

[0035] (3) Assemble the reaction kettle and react at 180° C. for 12 hours. After the reaction, pour off the supernatant, purify by centrifugation, and redisperse in nitrogen methyl pyrrolidone to prepare copper sulfide-nitromethyl pyrrolidone dispersant.

Embodiment 3

[0037] (1) First weigh 1.0g of polyvinylpyrrolidone, add 15mL of nitrogen methylpyrrolidone to dissolve and disperse, wait until the solution becomes clear and transparent, add 1mmoL copper sulfate pentahydrate solid under magnetic stirring, and continue to stir for 20 minutes to obtain bright green and transparent solution;

[0038] (2) Weigh 4mmoL of sulfur powder in the lining of a 25mL polytetrafluoroethylene reactor, then pour the above solution into the lining and stir for 10 minutes;

[0039] (3) Assemble the reaction kettle and react at 140° C. for 8 hours. After the reaction, pour off the supernatant, purify by centrifugation, and redisperse in nitrogen methyl pyrrolidone to prepare copper sulfide-nitromethyl pyrrolidone dispersant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com