High-salinity sewage natural cooling crystallizer

A technology of frozen crystallizer and high-salt sewage, which is applied in the direction of frozen water/sewage treatment, etc., to achieve the effects of low energy consumption and cost, compact structure and high desalination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

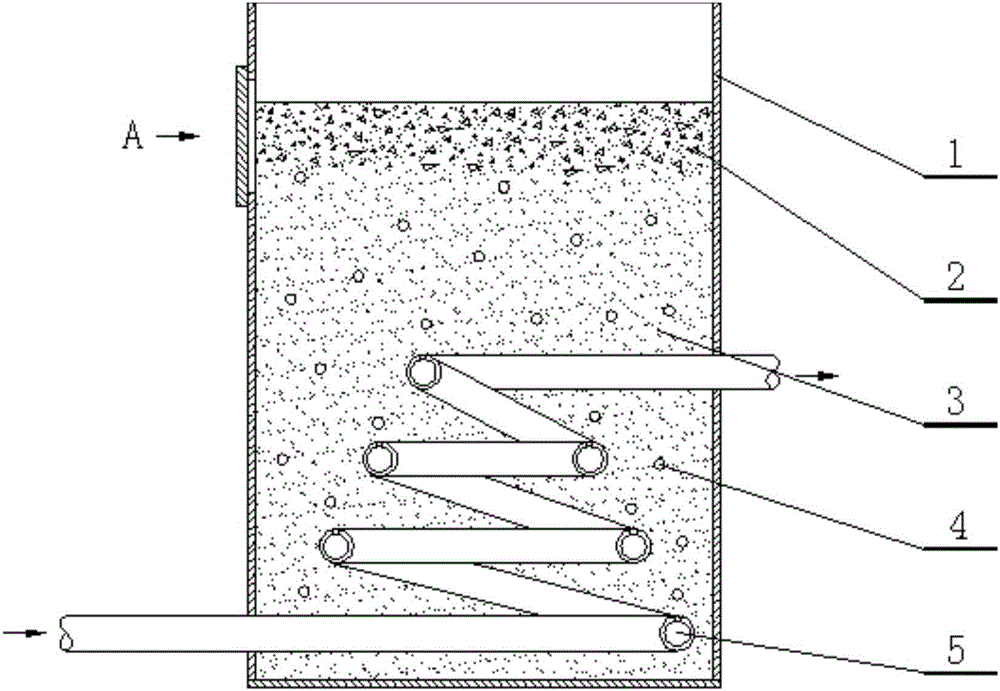

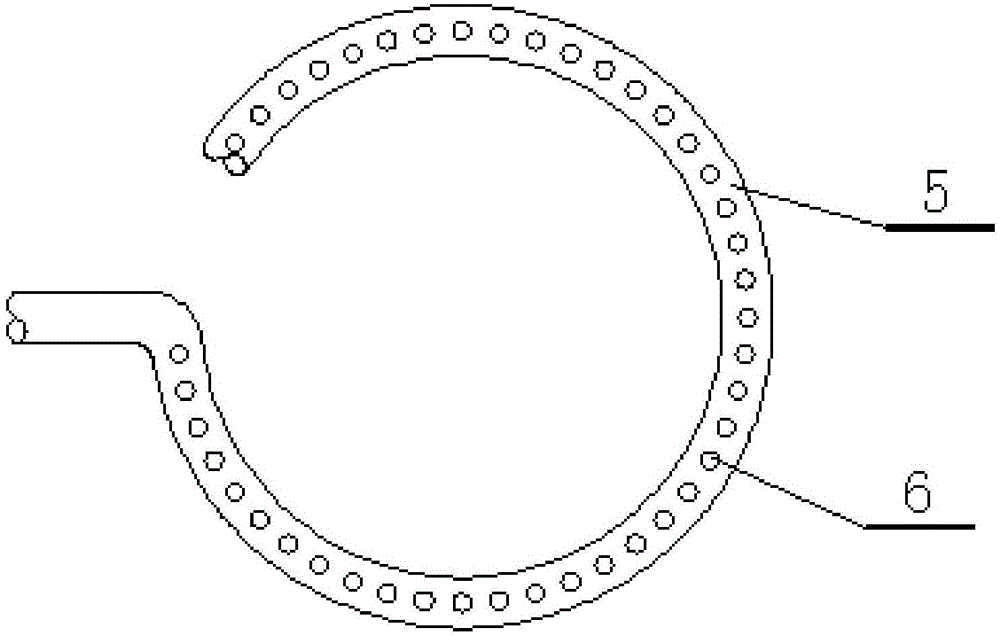

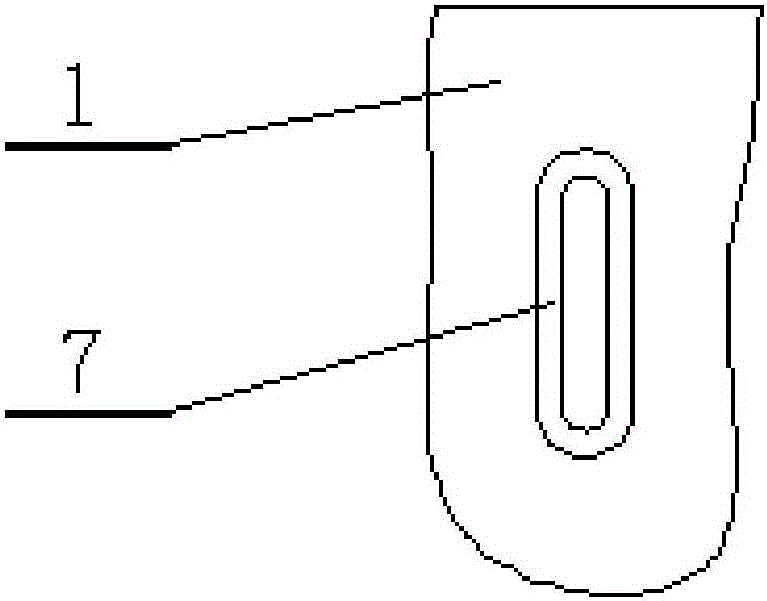

[0015] like figure 1 , 2 , the crystallizer shown in 3, wherein 1 is the crystallizer, 2 is ice crystal, 3 is high-salt sewage or concentrated brine, 4 is cold air, 5 is the exhaust pipe, 6 is the exhaust hole, and 7 is the inlet of the exhaust pipe breath. When in use, the air inlet of the coil is connected with the air pump, and the air injected by the air pump is cold air under natural climate. The crystallizer can be in the shape of a barrel or a cuboid trough. The form of the row pipe 5 can be made into a disk or a plurality of parallel pipes according to the form of the crystallizer, and its purpose is to make the high-salt sewage or concentrated brine in the crystallizer evenly contact with the cold air discharged from the row pipe.

[0016] Peristaltic stirring is to use the bubbles formed by cold air in the liquid. During the process of rising at a moderate speed, it takes away the heat in the water or the solidification heat during crystallization. At the same tim...

Embodiment 2

[0019] like image 3 , 4 , the crystallizer adopts a barrel shape, and the peristaltic stirring form is driven by a motor and a reducer to stir the high-salt sewage or concentrated brine 3 that needs to be treated in the crystallizer 1, and the rotation speed of the frame stirrer is controlled at About 3 revolutions per minute. According to the change of the weather, the rotation speed of the agitator is adjusted in the range of 1-20r / min. The purpose is to make the high-salt sewage or concentrated brine in the crystallizer evenly dissipate heat. An elastic material 9 is installed on the edge of the frame stirrer, so that the elastic material contacts the inner wall of the crystallizer, which can effectively prevent ice from forming on the surface of the inner barrel of the crystallizer during the crystallization process, and affect the heat transfer efficiency of the heat transfer interface. The low speed rotation of the frame stirrer serves the same purpose as peristaltic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com