Heavily Tb<3+> doped phosphate glass core composite optical fiber and preparation method thereof

A technology of phosphate glass and composite optical fiber, applied in the field of optical fiber, can solve the problems of destroying the glass network structure and crystallization, and achieve the effect of excellent performance and avoiding the problem of glass drawing and crystallization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) A highly doped Tb 3+ Phosphate glass preparation: the traditional melting-annealing method is adopted, and the raw material formula of the glass material is composed of the following substances in terms of weight percentage:

[0026]

[0027] Weigh the raw materials according to the above ratio, mix them evenly, melt them in a corundum crucible at 1200°C for 5 hours, and obtain a bulk phosphate core glass after precision annealing. Its Verdet constant is -0.25min / 0e·cm@632.8nm, -0.075min / 0e·cm@1064nm.

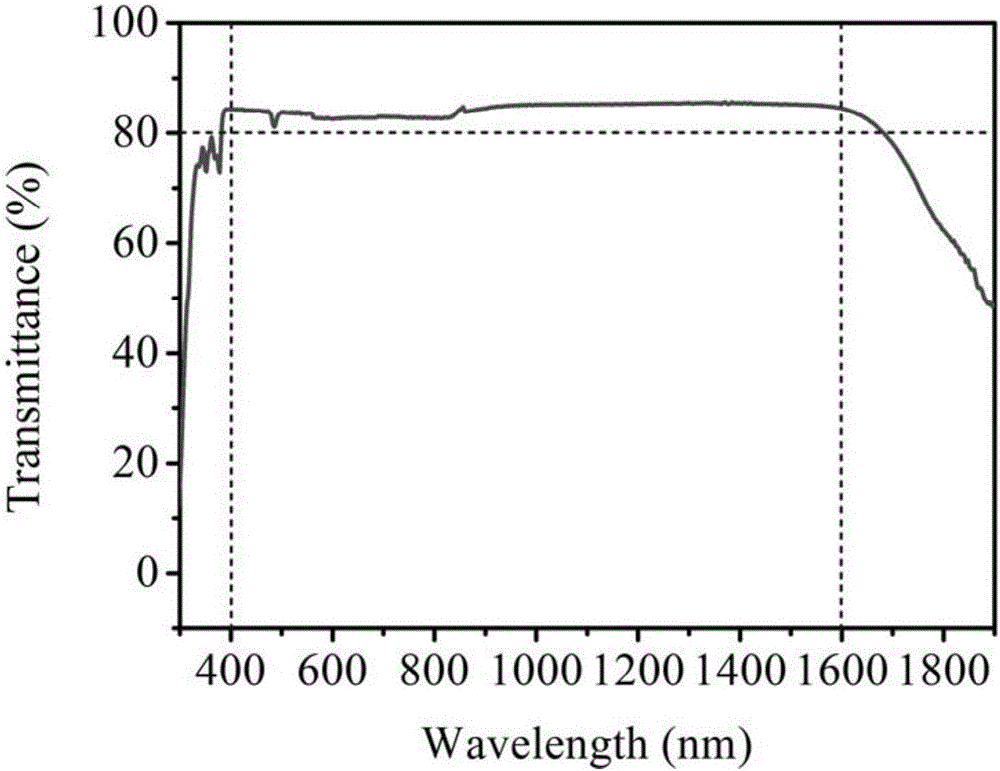

[0028] see figure 1 , is the highly doped Tb prepared in this example 3+ The light transmittance curve of phosphate glass, where the abscissa is the incident wavelength, and the ordinate is the light transmittance. Depend on figure 1 It can be seen that in the range of 400-1600nm, highly doped Tb 3+ The light transmittance of phosphate glass is greater than 80%.

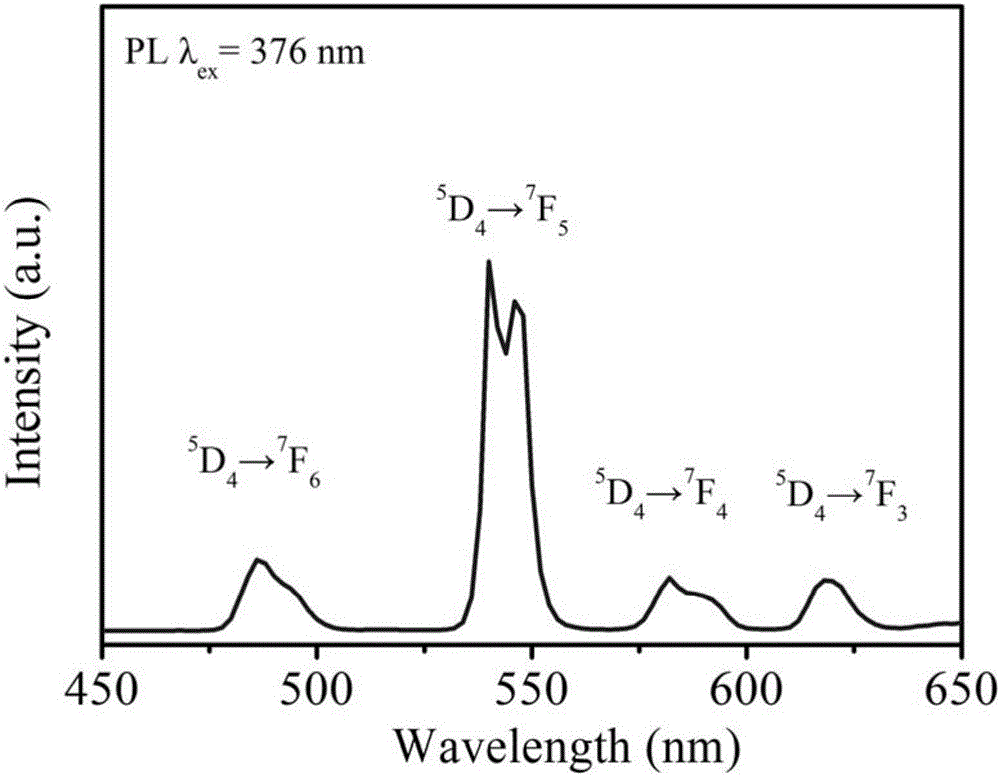

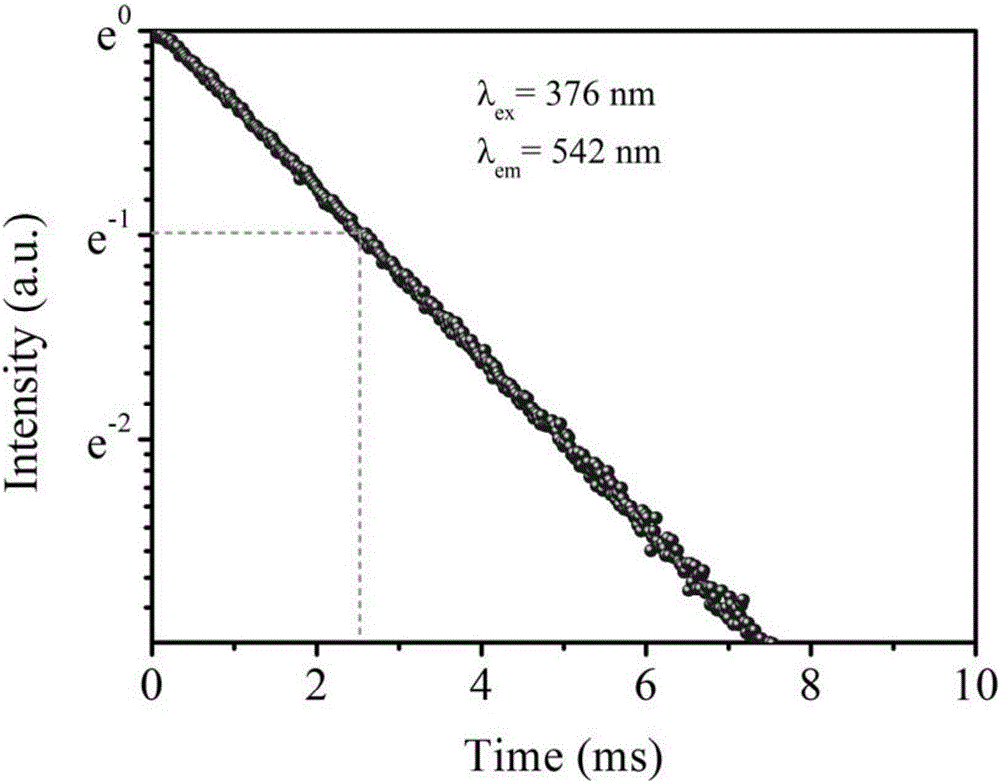

[0029] see figure 2 , is the highly doped Tb prepared in this example 3+ The emission spectr...

Embodiment 2

[0035] (1) A highly doped Tb 3+ Phosphate glass preparation: the traditional melting-annealing method is adopted, and the raw material formula of the glass material is composed of the following substances in terms of weight percentage:

[0036]

[0037] Weigh the raw materials according to the above ratio, mix them evenly, melt them in a corundum crucible at 1250°C for 4 hours, and obtain a bulk phosphate core glass after precision annealing. Highly doped Tb 3+ Phosphate core glass has a light transmittance greater than 80% in the range of 400-1600nm. Under the pump of 376nm, strong green light can be emitted at 542nm. Its fluorescence lifetime is 2.4ms and its Verdet constant is -0.29min. / 0e·cm@632.8nm, -0.079min / 0e·cm@1064nm.

[0038] (2) Machining of preform: highly doped Tb after precision annealing 3+ Phosphate bulk core glass is processed into a glass cylinder with a length of 7cm and a diameter of 4.5mm, and the surface of the cylinder glass is mechanically and c...

Embodiment 3

[0041] (1) A highly doped Tb 3+ Phosphate glass preparation: the traditional melting-annealing method is adopted, and the raw material formula of the glass material is composed of the following substances in terms of weight percentage:

[0042]

[0043] Weigh the raw materials according to the above ratio, mix them evenly, melt them in a corundum crucible at 1280°C for 4 hours, and obtain a bulk phosphate core glass after precision annealing. Highly doped Tb 3+ Phosphate core glass has a light transmittance greater than 80% in the range of 400-1600nm. Under the pump of 376nm, strong green light can be emitted at 542nm. Its fluorescence lifetime is 2.3ms and its Verdet constant is -0.32min. / 0e·cm@632.8nm, -0.082min / 0e·cm@1064nm.

[0044] (2) Machining of preform: highly doped Tb after precision annealing 3+ Phosphate bulk core glass is processed into a glass cylinder with a length of 7cm and a diameter of 4.5mm, and the surface of the cylinder glass is mechanically and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Field constant | aaaaa | aaaaa |

| Fluorescence lifetime | aaaaa | aaaaa |

| Field constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com