Arylene ether nitrile proton exchange membrane including side chain with flexible sulfonic acid ion cluster structure and preparation method thereof

A technology of proton exchange membrane and polyarylether nitrile, which is applied in the field of polymer proton exchange membrane and its preparation, can solve the problems of poor dimensional stability, insufficient oxidation resistance stability, poor ion conductivity, etc., and achieve a simple and good preparation method. Ionic conductivity, the effect of easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

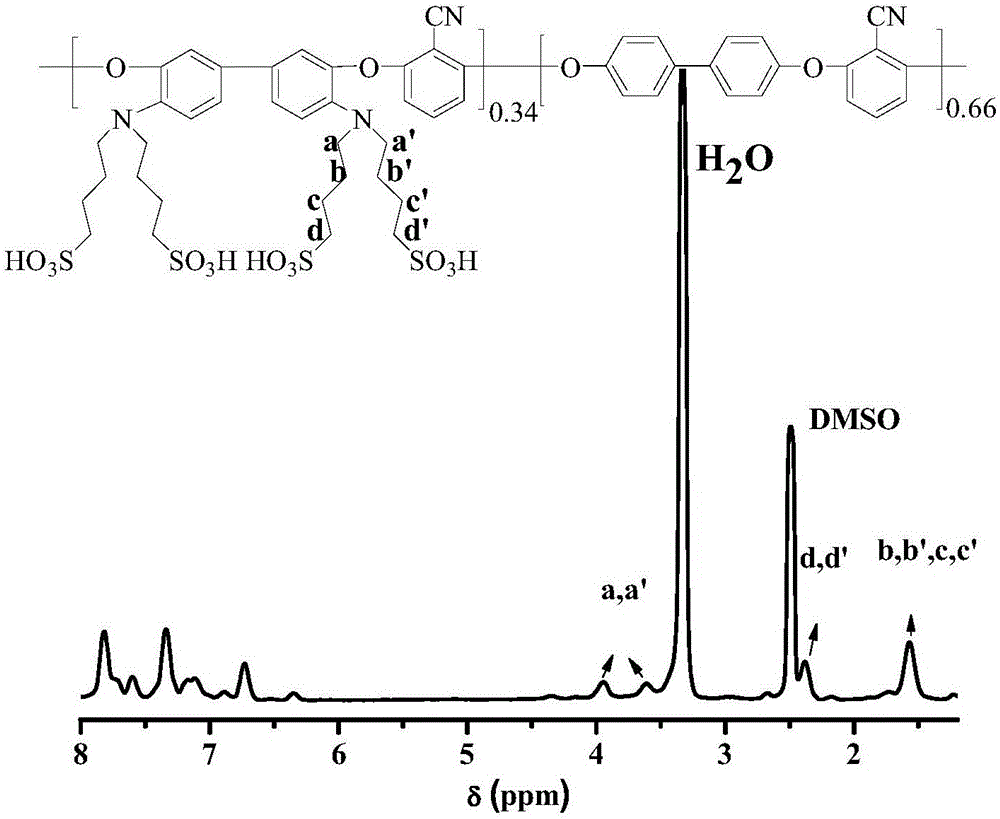

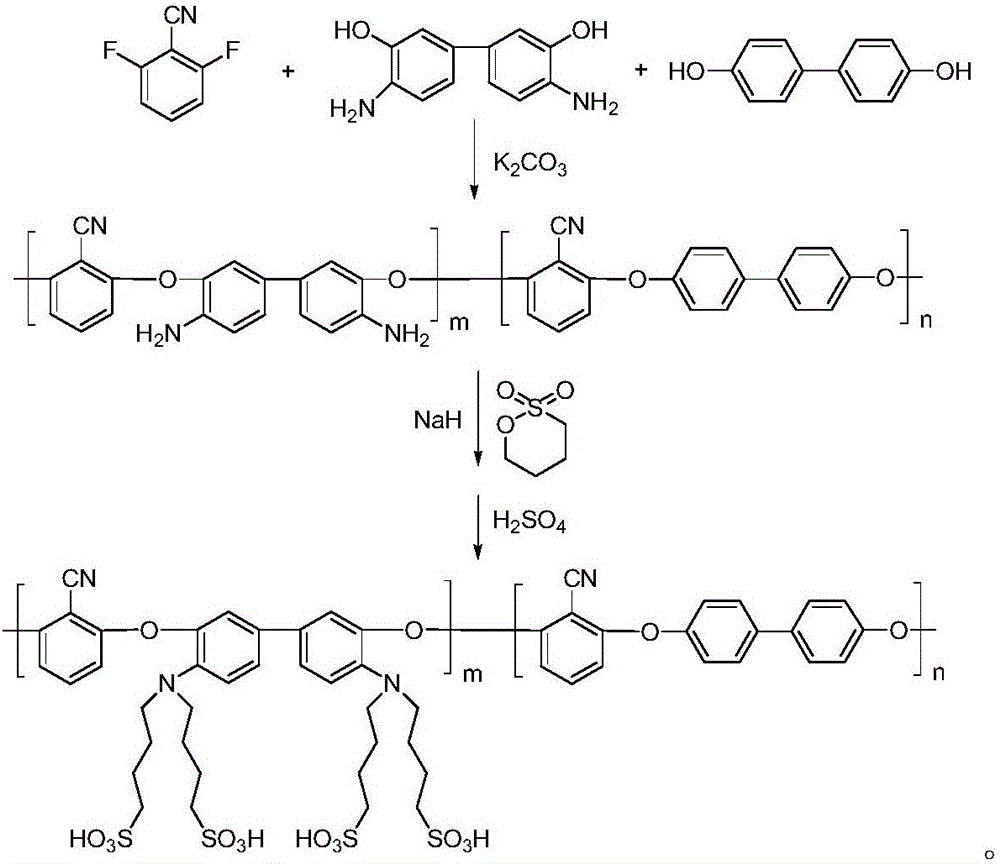

[0019] (1) Preparation of polyaryl ether nitrile polymer containing amine group structure

[0020] In a 100ml dry three-necked flask equipped with mechanical stirring and nitrogen protection, respectively add 1.3910g (10mmol) of 2,6-difluorobenzonitrile, 0.7352g (taking ionized structural unit content x=0.34 as an example) and 1.2290g (6.6mmol) of biphenol, 1.3821g (10mmol) of potassium carbonate, 16.4ml (29.3ml) of N-methylpyrrolidone, after stirring the reaction at 150°C for 3h, the reaction was terminated, and the reaction solution was poured into ethanol After further filtering and washing, a polyaryl ether nitrile polymer containing an amine group structure is obtained with a yield of 99%.

[0021] (2) Preparation of polyaryl ether nitrile polymer with sulfonic acid sodium salt structure in side chain

[0022] In a 100ml dry three-necked flask equipped with mechanical stirring and nitrogen protection, 2g of polyarylether nitrile polymer containing amine group structure (taking ...

Embodiment 2

[0026] (1) Preparation of polyaryl ether nitrile polymer containing amine group structure

[0027] In a 100ml dry three-necked flask equipped with mechanical stirring and nitrogen protection, respectively add 1.3910g (10mmol) of 2,6-difluorobenzonitrile, 0.7352g (taking ionized structural unit content x=0.34 as an example) and 1.2290g (6.6mmol) of biphenol, 1.7940g (13mmol) of potassium carbonate, 29.3ml of N-methylpyrrolidone, after stirring the reaction at 130°C for 6h, the reaction was terminated, the reaction solution was poured into ethanol, and further filtered, After washing, a polyarylene ether nitrile polymer containing an amine group structure was obtained with a yield of 99%.

[0028] (2) Preparation of polyaryl ether sulfone ketone proton exchange membrane material containing polysulfonic acid structure

[0029] In a 100ml dry three-necked flask equipped with mechanical stirring and nitrogen protection, dissolve 2g of polyaryl ether nitrile polymer with amine group struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com