Method for wet separation and recovery of valuable metal from Kaldo furnace smelting slag

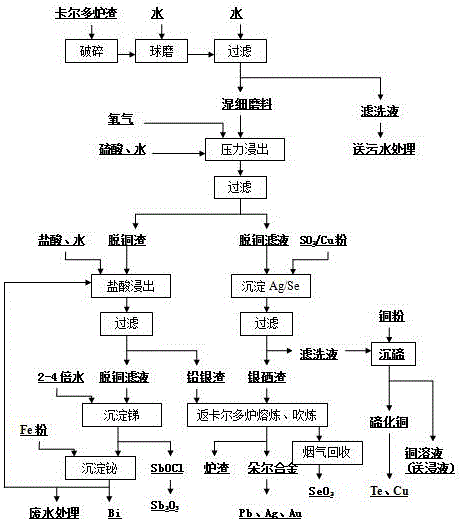

A wet separation, valuable metal technology, applied in the directions of non-metallic elements, chemical instruments and methods, process efficiency improvement, etc., can solve the problems affecting the copper smelting system and copper electrolysis system, the large amount of smelting slag, and the lack of consideration of antimony and bismuth. The recovery of selenium and tellurium, etc., achieves the effect of good compatibility, high enrichment, and avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method for wet separation and recovery of valuable metals in Kaldor furnace smelting slag, carried out according to the following steps:

[0022] (1) Sampling and crushing

[0023] A total of 8 kg of Kaldor furnace smelting slag was used in the comprehensive workshop of Baiyin Nonferrous Group Company to carry out a small test. All the Kaldor furnace smelting slag samples were crushed into small particles with a particle size of 0-5 mm for use. The raw material composition and content of Kaldor furnace smelting slag are: Pb 28.89%; S 3.58%; Na 10.48%; Ba 7.20%; Cu 12.39%; Sb 10.18%; Bi 6.47%; Ag4.82%; As 1.71%; Si 1.57%; Ca 0.72%; Mg 0.78%; Sn 1.14%; K 0.57%; Fe 1.55%; Cl 0.45%; Al 0.26%; Te 0.20%; Se 0.32%; Ni 0.29%.

[0024] (2) Grinding and water leaching desalination

[0025] Weigh 500g of the crushed sample and put it into a ball mill, add 500g of water, and grind for 10 minutes. At this time, the mineral fineness is -200 mesh and 95%, then rinse with 500g of w...

Embodiment 2

[0035] (1) The smelting slag from Kaldor furnace in the comprehensive workshop of Baiyin Nonferrous Metals Group Co., Ltd. was used to carry out a small test.

[0036] (2) Weigh 150g of the crushed sample and put it into a ball mill, add 150g of water, and grind for 10 minutes. At this time, the mineral fineness is 98% at -200 mesh.

[0037] (3) Decopper removal by pressure acid leaching

[0038]Weigh 100g of the ground desalted material and put it into a 1L small autoclave, add 400g of water and 20g of concentrated sulfuric acid with a mass fraction of 98%. Heating was stopped, and a certain pressure was controlled at this time, and nitrogen was removed by releasing partial pressure in the kettle. Then close the valve and feed oxygen into the autoclave for 5 hours. After the pressure in the autoclave reaches 12MPa and the temperature in the autoclave reaches 180°C, cool it down. , filtered, and washed with water to obtain copper-removing slag and copper-removing solution. ...

Embodiment 3

[0046] (1) The smelting slag from Kaldor furnace in the comprehensive workshop of Baiyin Nonferrous Metals Group Co., Ltd. was used to carry out a small test.

[0047] (2) Weigh 150g of the crushed sample and put it into a ball mill, add 150g of water, and grind for 10 minutes. At this time, the mineral fineness is 98% at -200 mesh.

[0048] (3) Decopper removal by pressure acid leaching

[0049] Weigh 100g of the ground desalted material and put it into a 1L small autoclave, add 400g of water, and 50g of concentrated sulfuric acid with a mass fraction of 98%. Heating was stopped, and a certain pressure was controlled at this time, and nitrogen was removed by releasing partial pressure in the kettle. Then close the valve and feed oxygen into the autoclave for 6 hours. After the pressure in the autoclave reaches 10MPa and the temperature in the autoclave reaches 180°C, cool down. After the pressure leaching operation is completed, the temperature of the feed liquid is reduced ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com