Novel burner-type biomass burning machine adopting sleeves and moving grate

A movable grate and burner technology, which is applied in the direction of combustion methods, combustion equipment, and solid fuel combustion, can solve the problems of poor applicability, poor continuous stability, and large assembly volume, etc., and achieve anti-coking performance and good performance. , Simple operation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

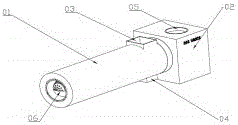

[0030] like figure 1 In the shown embodiment, a new burner-type casing movable grate biomass burner provided by the present invention can be divided into a front reaction chamber and a rear control auxiliary chamber according to the difference in specific functions and operating temperatures; The front reaction chamber is cylindrical, and the exterior includes the nozzle housing (1), the biomass feed port (3), the burnt ash slag discharge port (4) and the burner nozzle (6); the rear reaction chamber includes Main body casing (2), fan suction port (5), intelligent control panel, etc.

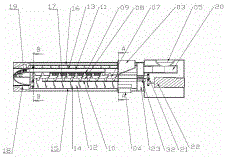

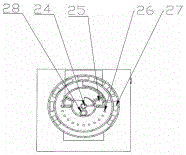

[0031] The preferred combination figure 2 , 3. In the specific embodiment shown in 4, the front reaction chamber of the burner is composed of the gasification bed tube wall (10) [the upper part is the gas material separation screen (09)], the gasification gas collection and premixing from the inside to the outside. The chamber tube wall (13), the fixed carbon combustion chamber tube wall (15)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com