A method of heating NOx water injection to improve the performance of combined cycle power plants

A combined cycle and power plant technology, applied in the fields of combustion methods, combined combustion mitigation, lighting and heating equipment, etc., can solve problems such as low practicability and applicability of solutions, increased initial investment, and increased plant area for auxiliary equipment, etc. The effect of reducing the amount of closed cooling water, reducing the initial investment and reducing the electric power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Best practice:

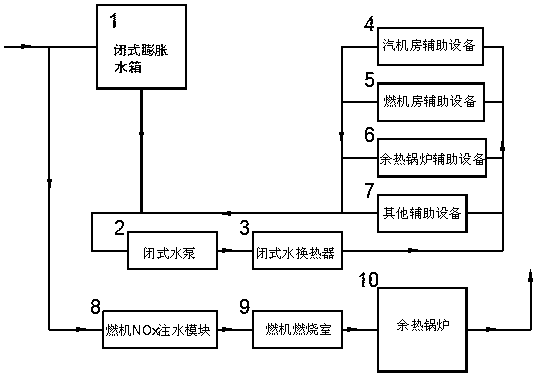

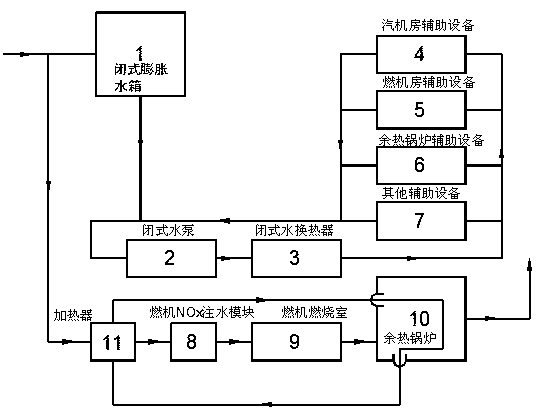

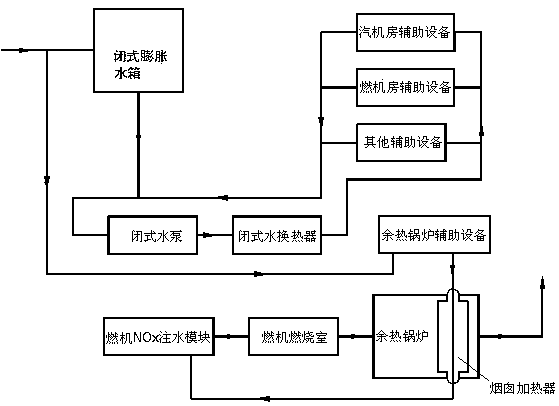

[0033] Refer to attached image 3 , heating NO X A method for improving the performance of a combined cycle power plant by water injection, comprising the following steps:

[0034] 1. First, separate the auxiliary equipment of the waste heat boiler in the closed cooling water system of the conventional combined cycle power plant into an open cooling water system. The open cooling water system includes auxiliary equipment such as high and medium pressure feed water pumps and condensate circulation pumps. If If there is an economizer circulating pump in the system, this equipment is also included in the open cooling water system, and the rest of the closed cooling water systems are adjusted accordingly according to the amount of circulating cooling water;

[0035] 2. Secondly, an independent pipeline provides desalted water as cooling water to the auxiliary equipment of the waste heat boiler, and performs heat exchange with the cooler equipped with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com