High-temperature gas cooled reactor primary helium circulator electrical penetration assembly and machining method thereof

A technology of high-temperature gas-cooled reactors and electrical penetrations, which is applied in the fields of reducing greenhouse gases, reactors, and nuclear engineering. It can solve problems such as poor insulation performance and pressure bearing capacity, poor mechanical performance and sealing performance, and short service life. Strong insulation performance and pressure bearing capacity, good mechanical performance and sealing performance, good shock resistance and cushioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

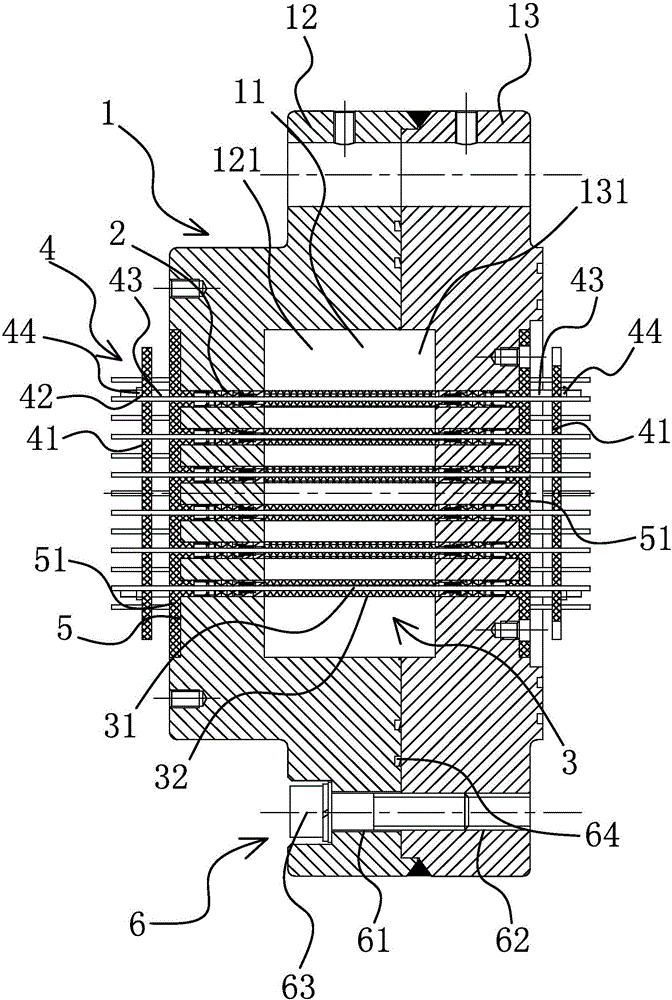

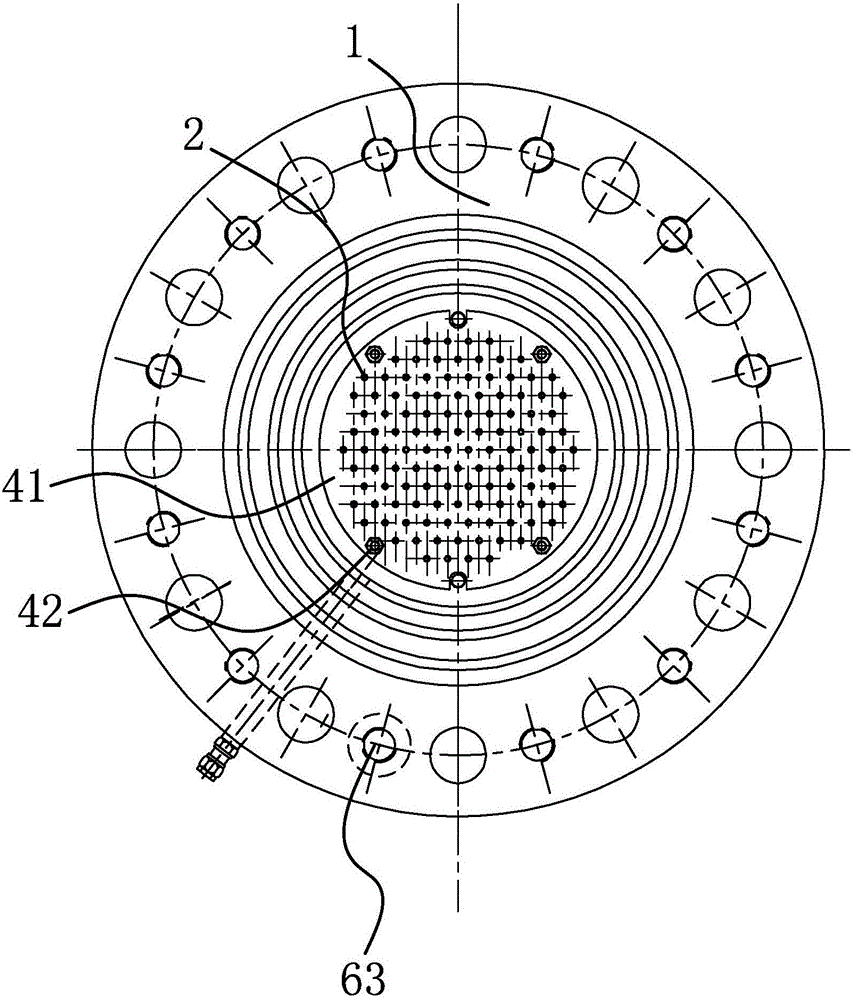

[0025] Such as Figure 1-2 As shown, the electrical penetrating part of the main helium fan of the high temperature gas-cooled reactor includes a stainless steel main body flange 1 with a cavity 11, and the stainless steel main body flange 1 is provided with a plurality of through holes 2 axially penetrating the entire stainless steel main body flange 1, Conductor assemblies 3 that can extend to the outside of both ends of the stainless steel body flange 1 are perforated in the through holes 2, and the conductor assemblies 3 include metal transmission conductors 31 made of Kovar alloy materials, and the outer surface of the metal transmission conductors 31 is The ceramic positioning sleeve body 32 is provided by sintering and the ceramic positioning sleeve body 32 is connected with the metal transmission conductor 31 as an integral st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com