Secondary battery anode material, preparation method thereof and battery containing anode material

A secondary battery and negative electrode material technology, applied in the direction of secondary batteries, battery electrodes, negative electrodes, etc., can solve the problem that it is difficult to ensure good contact between conductive carbon and active materials, conductive carbon cannot fully function, and kinetic performance deteriorates, etc. problems, to achieve the effect of easy large-scale production, easy control, and large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present application also relates to a preparation method of the secondary battery negative electrode material, at least including the following steps:

[0048] (1) mixing the core particles with the precursor of the carbon layer to form a first modified material coated with the precursor of the carbon layer;

[0049] (2) mixing the first modified material with the conductive carbon particles or the precursor of the conductive carbon particles, and dispersing the conductive carbon particles or the precursor of the conductive carbon particles on the surface of the first modified material;

[0050] (3) Carbonizing the product obtained in step (2) to obtain a negative electrode material for a secondary battery.

[0051]This application adopts the method of mixing twice and carbonizing once. First, the precursor of the connecting carbon layer coated on the surface of the inner core particle is carbonized to form a carbon layer with a connecting effect, and then the precu...

Embodiment

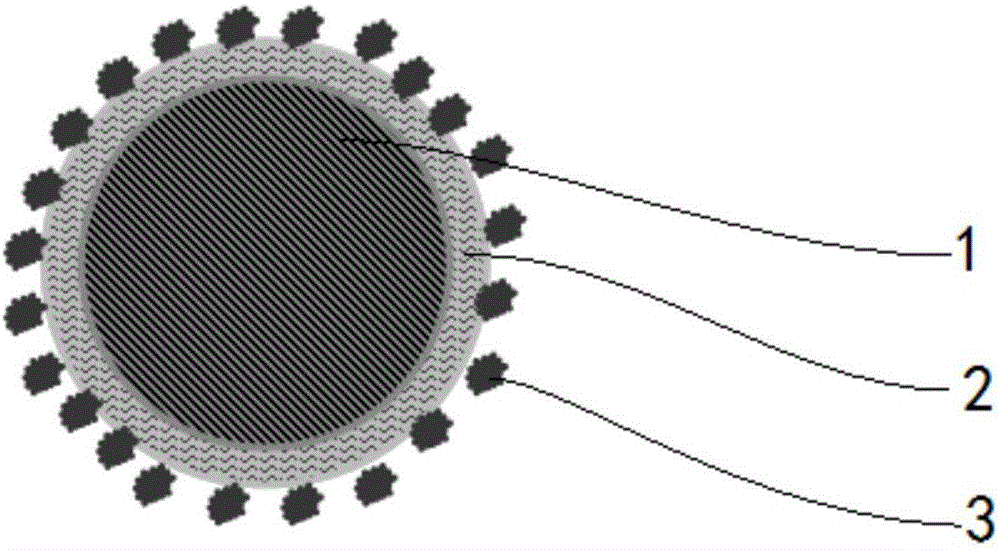

[0062] A negative electrode material for a secondary battery, comprising core particles 1, a connection carbon layer 2 coated on the surface of the core particle, and conductive carbon particles 3 distributed on the surface of the connection carbon layer.

[0063] The preparation method is:

[0064] 1. Mix the core particles and the precursor connected to the carbon layer at high speed, and the mixing time is 3 to 5 hours; the mixing speed is 900 to 1500r / min; the weight ratio of the core particles: the precursor connected to the carbon layer is recorded as A; Form the first modified material coated with the precursor of the connected carbon layer; the selection of raw materials is shown in Table 1, and the mixing conditions are shown in Table 2;

[0065] 2. Stir and mix the first modified material with conductive carbon particles or the precursor of conductive carbon particles at a high speed for 0.5 to 3 hours; the speed of mixing and stirring is 300 to 600r / min; conductive ...

experiment example

[0080] Preparation of battery:

[0081] 1. Mix graphite, conductive carbon and binder at a mass ratio of 97:1:2; mix the negative electrode material and binder of Examples 1 to 14 of this application at a mass percentage of 98:2, and control the solid content at 50%. Coating on the copper foil current collector, drying in vacuum to prepare negative pole pieces 1-14;

[0082] 2. The ternary positive electrode sheet prepared by traditional mature technology, 1mol / L LiPF 6 / EC+DMC+EMC (v / v=1:1:1) electrolyte, Celgard2400 diaphragm, made into soft pack cells 1~14 by winding process.

[0083] The charging performance of the material was tested by the following methods:

[0084] Using the LAND battery test system of Wuhan Jinnuo Electronics Co., Ltd., the charging and discharging voltage is limited to 2.8-4.2V. According to the actual measured nominal capacity C0, the secondary batteries under each group number are divided into 10 groups, respectively. 1.0C, 1.2C, 1.4C, 1.5C, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com