Dispersant suitable for lubricant formulations

A dispersant and reaction product technology, applied in lubricating compositions, additives, petroleum industry, etc., can solve problems such as smoke-induced wear, pollutants deposited on metal surfaces, and lubricant viscosity increase

- Summary

- Abstract

- Description

- Claims

- Application Information

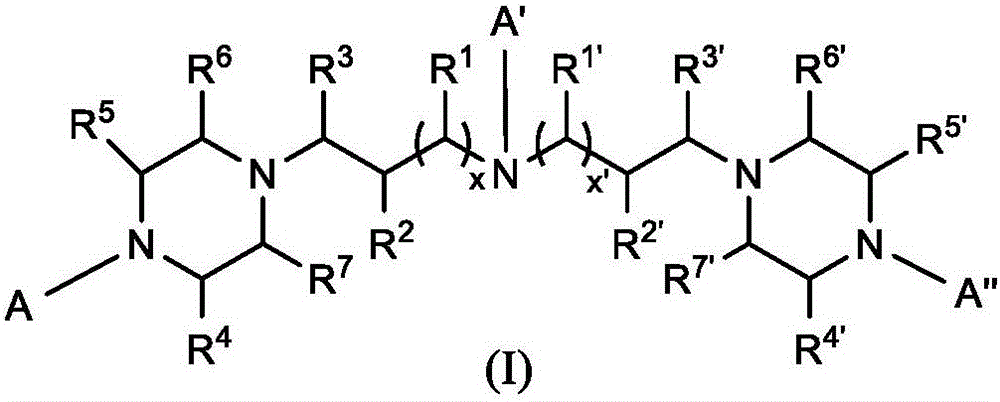

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

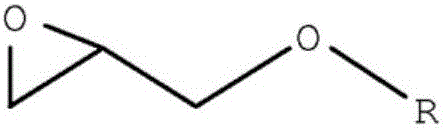

[0038] Synthetic Glycidyl Ether

[0039] Glycidyl Ether of Polypropylene Glycol Methyl Ether ("GE1")

[0040] A 1000 mL round bottom flask using overhead stirring was charged with 407.8 g of 1000 g / mol polypropylene glycol methyl ether (from Aldrich with a number average molecular weight of 1130 g / mol and a Mw of 1170 g / mol) and 0.6 g of trifluoro Boron compound diethyl ether. The solution was warmed to 70°C and the dropwise addition of 41.10 g (1.1 molar equivalents) of epichlorohydrin was started. The maximum temperature reached during the reaction was 75°C. Stir overnight at 70° C., then dilute the black solution with 53.2 mL of 50% by weight aqueous sodium hydroxide. The organic phase turned brown. Heat at 70°C overnight, then cool to ambient temperature (approximately 23-25°C). The lower aqueous phase was removed. The organic phase was washed with 62.5 g of water containing 17.8 g of sodium chloride. The solution was treated with 5 g of magnesium sulfate, filtered ...

example 1

[0046] Example 1 - GE1 product using aminoethylpiperazine (AEP)

[0047] A 500 mL round bottom flask using magnetic stirring and a water cooled condenser was charged with 37.55 g of GE1, 65.3 g of methanol and 1.4 g of N-aminoethylpiperazine, or "aminoethylpiperazine"). The solution was heated to reflux overnight, then cooled and evaporated on a rotary evaporator to give 38.76 g of a residue. The Mn of the residue was 1340 g / mol and the Mw was 2400 g / mol.

example 2

[0048] Example 2 - GE1 product (BPEA) using bis(2-(piperazin-1-yl)ethyl)amine

[0049] A 250 mL round bottom flask using magnetic stirring and a water cooled condenser was charged with 43.7 g GE1, 43 g methanol and 3.2 g BPEA. The solution was heated to reflux overnight, then cooled and evaporated on a rotary evaporator to give 46.9 g of a residue. The Mn of the residue was 1860 g / mol and the Mw was 3990 g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com