Intelligent citrus picking robot and citrus picking method

A technology for picking robots and citrus, applied in the field of agricultural robots, can solve the problems of unstable growth direction, failure of picking, and increase the distance of mechanical movement, and achieve the effects of rapid data collection speed, accurate digital signals, and improved work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

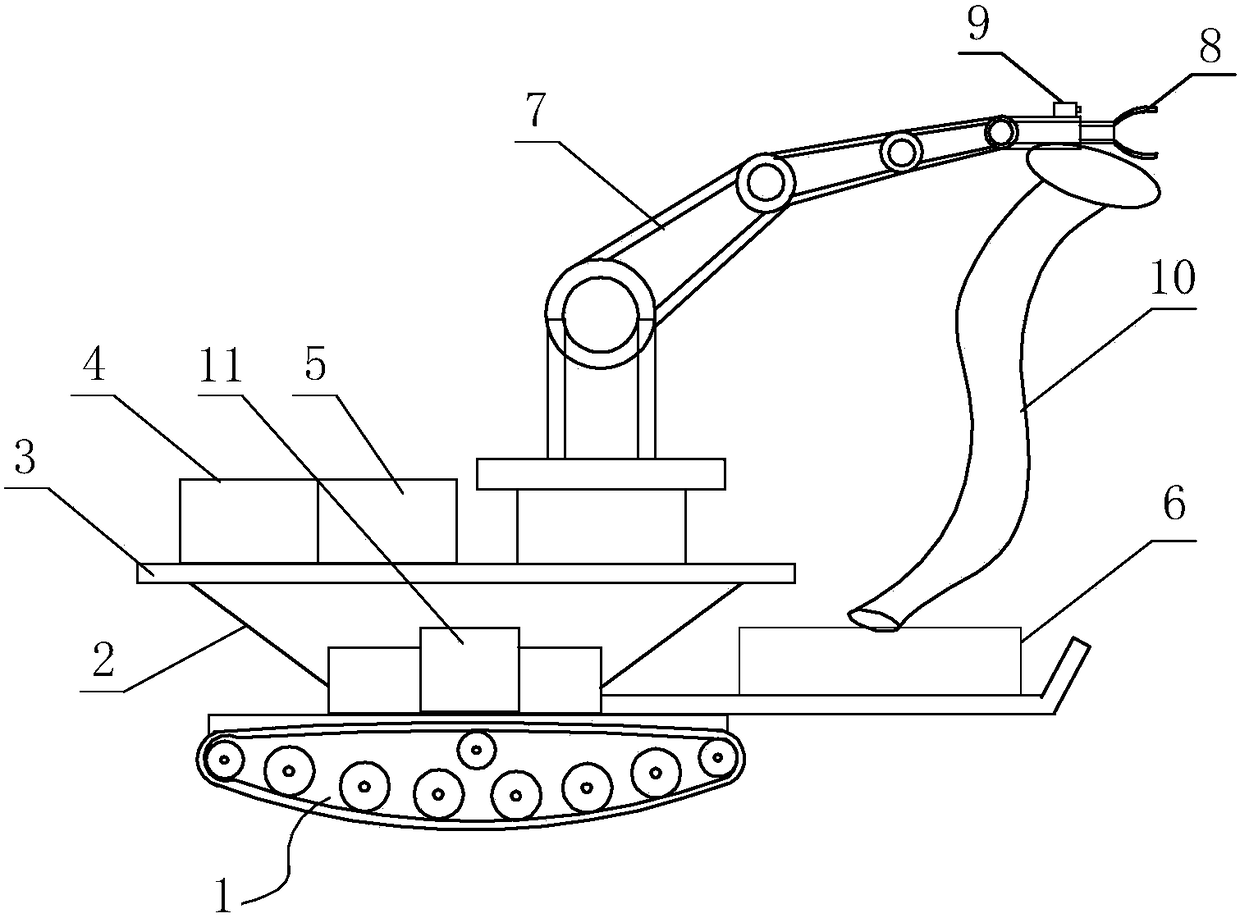

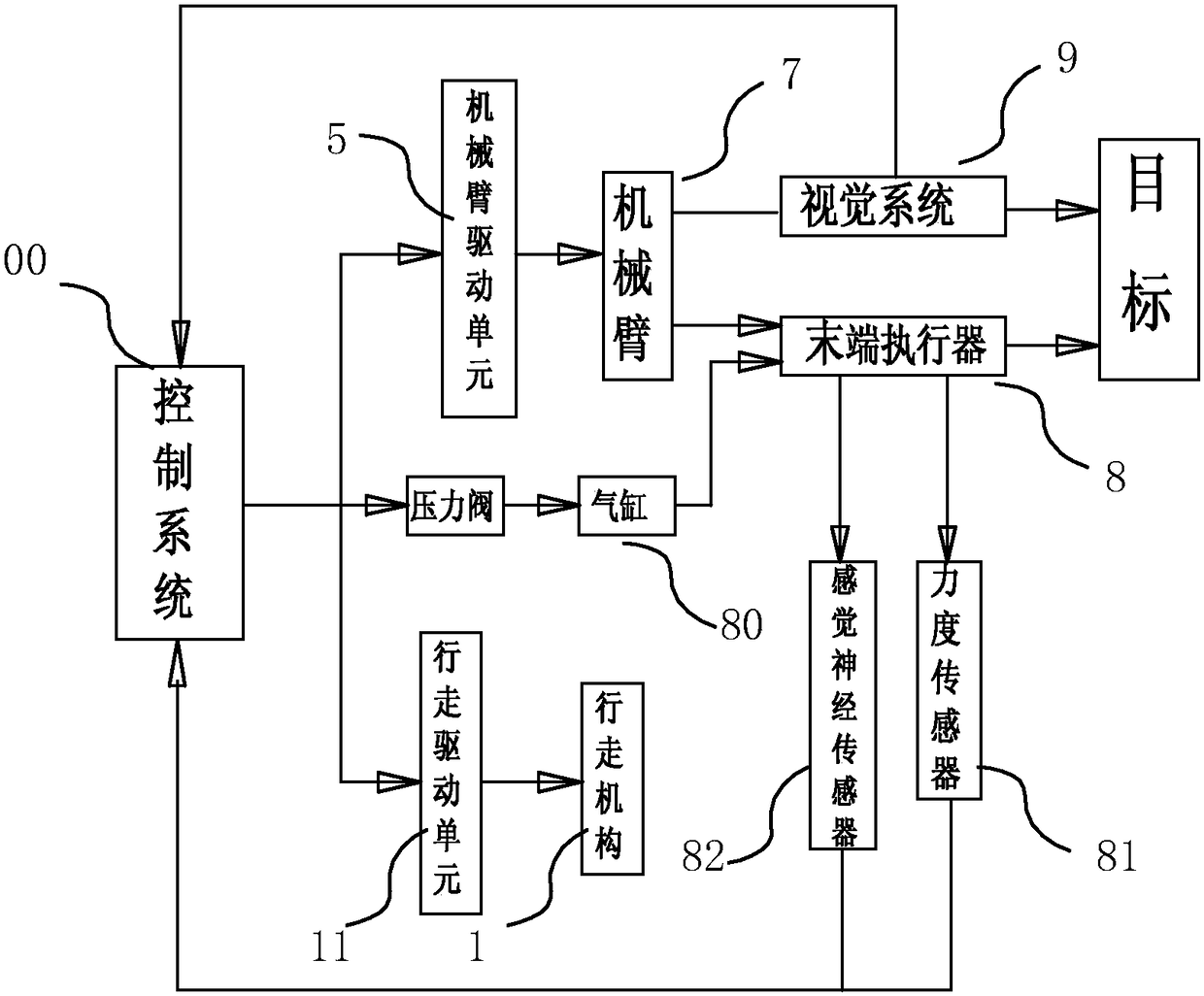

[0058] An intelligent citrus picking robot includes a walking mechanism 1, a mechanical arm 7, a worktable 3, a recovery device, a control system 00 and a power supply system 4, and the mechanical arm, the control system 00 and the power supply system 4 are installed on the workbench, and the mechanical The front end of the arm is provided with an end effector 8 and a vision system 9, the vision system is connected with the data of the control system, the control system controls the action of the manipulator through the manipulator driving unit 5, and the control system controls the walking through the walking drive unit 11 The action of the mechanism, the power supply system provides working power for the control system and the traveling mechanism;

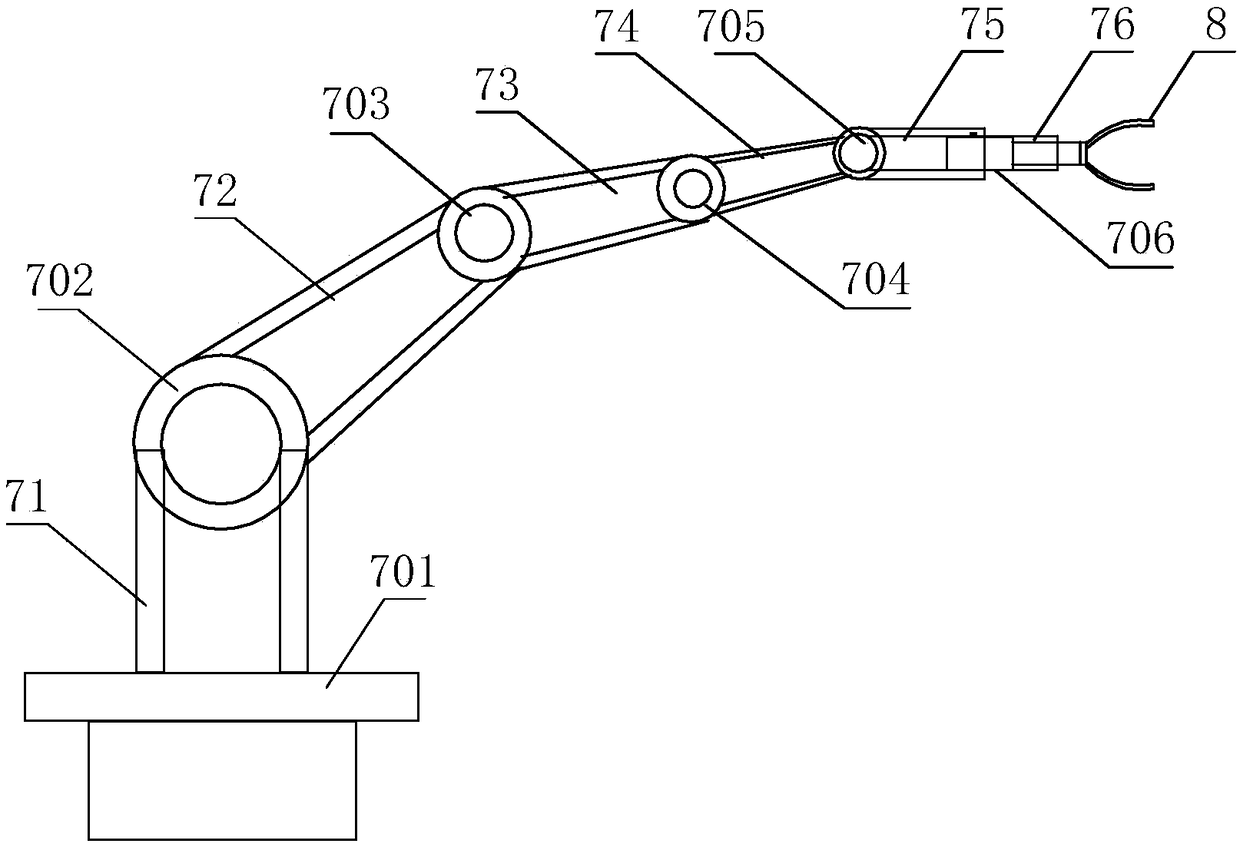

[0059] The mechanical arm 7 includes a first arm 71, a second arm 72, a third arm 73, a fourth arm 74, a fifth arm 75 and a sixth arm 76 which are movably connected in sequence: the first arm passes through the first joint 701 is...

Embodiment 2

[0066] A kind of citrus picking method, this method is to utilize the intelligent citrus picking robot of embodiment one to carry out the method for citrus picking, comprising the following steps:

[0067] S1: Start the walking mechanism to make the robot approach the fruit tree;

[0068] S2: Looking for citrus:

[0069] Drive the robotic arm into the fruit tree, the picking vision system searches for citrus to be picked, and sends the target position signal to the control system;

[0070] S3: Crawling citrus:

[0071] After the control system receives the signal from the picking vision system, it controls the mechanical arm to bring the end effector 8 close to the target, and controls the telescopic rotation mechanism and the cylinder in the fifth arm to make the flexible arm of the end effector 8 stretch out. and hold citrus;

[0072] S4: The strength sensor and the sensory nerve sensor detect the clamping force between the flexible arm and the fruit, and send the informa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com