High-sweetness and low-calorie liquid sweetening agent and preparation method thereof

A sweetener, low-calorie technology, applied in the directions of food ingredients containing natural extracts, food science, application, etc., can solve the problems of low-calorie syrup compositions that do not meet both solubility and stability requirements, and achieve direct economical improvement. Effectiveness, ease of use, good taste experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of compound sweetener: Mix sucralose and neotame evenly at a weight ratio of 10:90, set aside.

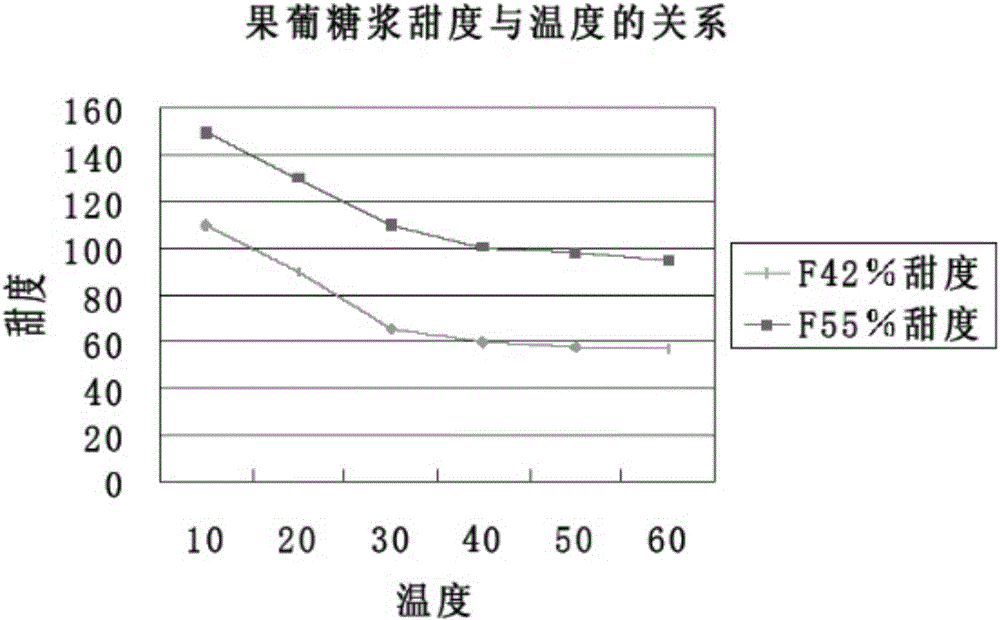

[0037] The preparation of liquid sweetener: take the high fructose syrup that fructose content is 42% (accounting for dry matter, mass fraction) as base material, take this material as benchmark, add compound sweetener successively, account for 1 / 10,000 of its weight Vanillin and 1% salt by weight are used to adjust the mouthfeel, mixed to obtain a mixed material, and the mixed material is stirred until its concentration is 77-78% to obtain a syrup base material, which is set aside.

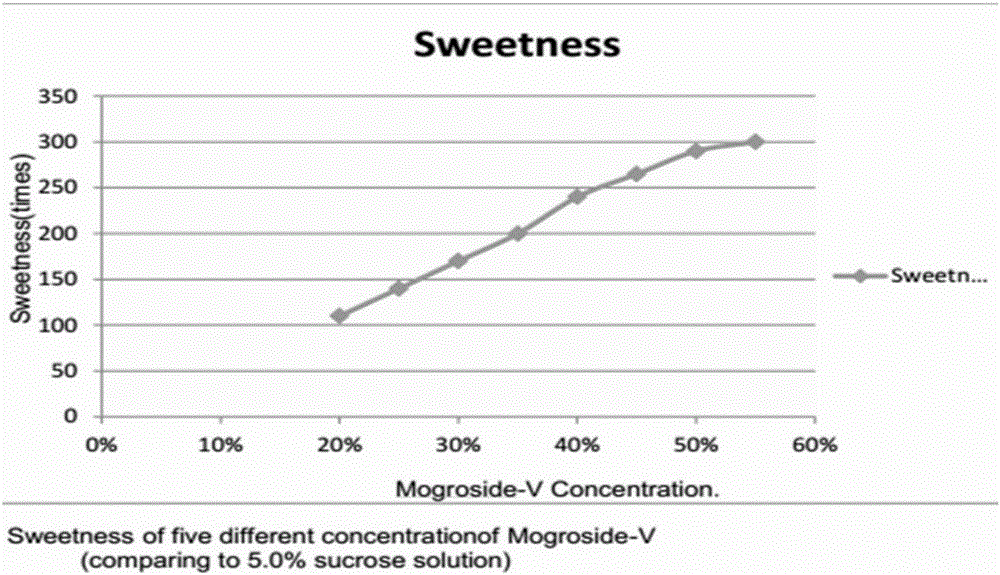

[0038] Mix the above-mentioned compound sweetener and syrup base evenly, and heat to 80-85° C. in a retort for 3-5 minutes. The addition ratio of the specific compound sweetener and the syrup base material can be adjusted appropriately according to the need for sweetness. The sweetness of the obtained liquid sweetener can be 2-20 times the sweetness of sucrose, and the cost can be o...

Embodiment 2

[0041] Preparation of compound sweetener: Mix sucralose and neotame evenly at a weight ratio of 92:8, set aside.

[0042] Preparation of liquid sweetener: take fructose syrup with a fructose content of 55% (accounting for dry matter, mass fraction) as the base material, and based on this material, add compound sweeteners successively, accounting for 1 / 10,000 by weight Vanillin and 1% by weight of salt are used to adjust the mouthfeel, mixed to obtain a mixed material, and the mixed material is stirred until its concentration is 77-78% to obtain a syrup base material, which is set aside.

[0043] Mix the above-mentioned compound sweetener and syrup base evenly, and heat to 80-85° C. in a retort for 3-5 minutes. The addition ratio of the specific compound sweetener and the syrup base material can be adjusted appropriately according to the need for sweetness. The sweetness of the obtained liquid sweetener can be 2-20 times the sweetness of sucrose, and the cost can be obtained af...

Embodiment 3

[0046] Preparation of compound sweetener: mix sucralose and neotame evenly in a weight ratio of 90:10, and set aside.

[0047] The preparation of liquid sweetener: take the fructose syrup that fructose content is 55% (accounting for dry matter, mass fraction) as base material, take this material as benchmark, add compound sweetener successively, account for 8 / 10,000 by weight The rose extract and 7% salt by weight are used to adjust the mouthfeel, and the mixed material is mixed to obtain a mixed material, and the mixed material is stirred until the concentration is 77-78% to obtain a syrup base material, which is set aside.

[0048] Mix the above-mentioned compound sweetener and syrup base evenly, and heat to 80-85° C. in a retort for 3-5 minutes. The addition ratio of the specific compound sweetener and the syrup base material can be adjusted appropriately according to the need for sweetness. The sweetness of the obtained liquid sweetener can be 2-20 times the sweetness of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com