Digitized design and 3D printing method for individualized ankle fracture brace

A 3D printing and ankle joint technology, applied in 3D modeling, electrical digital data processing, computing, etc., can solve problems such as long time-consuming, poor transmission, and displacement of fracture ends, so as to reduce experience and technical requirements and maintain The effect of fixation stability and avoiding displacement of fracture ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described in conjunction with the following examples.

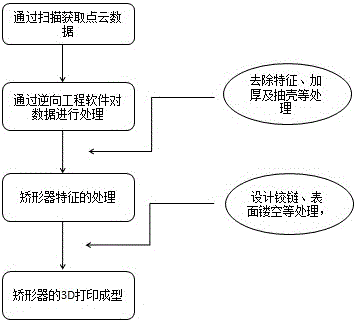

[0024] Such as figure 1 As shown, a digital design and 3D printing method of a personalized ankle fracture brace, step 1, use a laser three-dimensional scanner to scan the range from the upper segment of the affected tibia to the metatarsophalangeal joint plane, obtain point cloud data, scan according to the fracture The type keeps the ankle joint in the desired fixed position and collects complete point cloud data. The laser 3D scanner has no radiation and no trauma to the human body, and the acquisition process is fast and convenient.

[0025] Such as figure 1 As shown, step 2, import the point cloud data into the reverse engineering software for digital design, the specific steps are: step 2-1, modify the point cloud data in the reverse engineering software, package and construct a complete scan part skin The triangle slice model of the contour, step 2-2, smooth the skin conto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com