Operating temperature controlled multi-component membrane separation device and process thereof

An operating temperature, multi-component technology, used in semi-permeable membrane separation, separation/purification of carboxylate, membrane technology, etc. It can solve the operation of multiple sets of test equipment, single membrane separation function, and inability to operate multiple different membranes. Operation and other issues, to achieve the effect of improving integration and technological content, easier control of operating conditions, and more reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

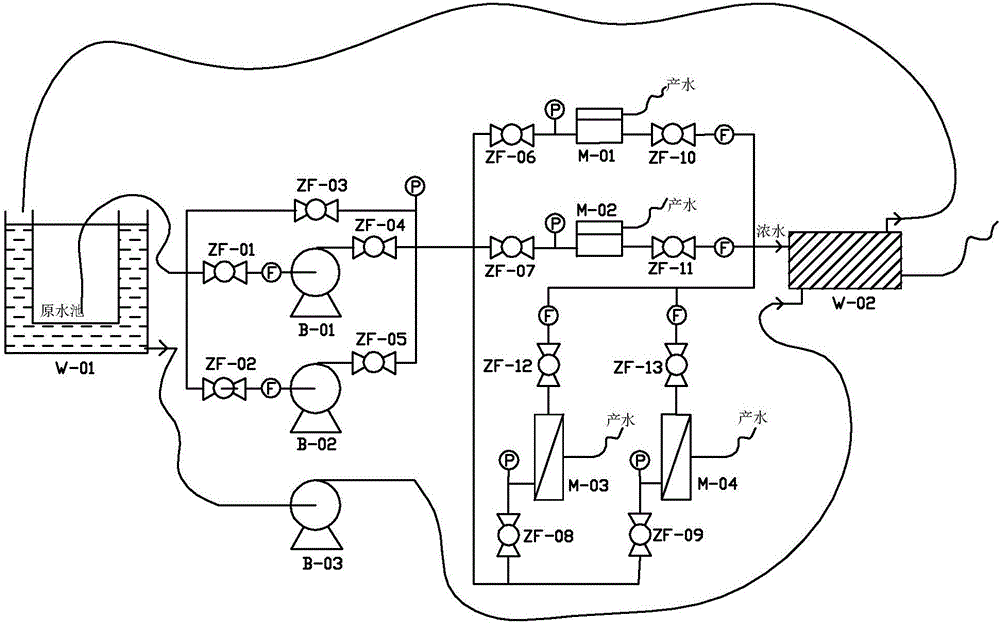

[0058] Example 1, ultrafiltration purification test of chlorogenic acid in honeysuckle water extract

[0059] Weigh 2.5kg of honeysuckle, add 1.0, 0.7, 0.5, 0.5, 0.5 times the amount of water to extract and reflux 5 times, each time for 1.5h, coarse filter, and combine the filtrates to obtain the honeysuckle water extract. The content of chlorogenic acid in the water extract is measured, and the water extract is used as the raw material solution for ultrafiltration to carry out ultrafiltration membrane separation. A flat-plate ultrafiltration membrane and a spiral-wound ultrafiltration membrane with a cut-off molecular weight (MWCO) of 20-50kDa were selected respectively, and a parallel test operation was carried out on the water extract of chlorogenic acid. The specific operation is as follows: install the flat membrane into the M-02 module, and install the spiral-wound membrane into the M-03 module. Chlorogenic acid is a heat-sensitive substance, and the temperature should ...

example 2

[0060] Example two, membrane method purification and concentration test of chlorogenic acid in honeysuckle water extract

[0061] According to example one method, obtain honeysuckle aqueous extract. Select spiral-wound ultrafiltration membranes and spiral-wound nanofiltration membranes with MWCO of 20-50kDa and 150-300Da, respectively, and put them into M-03 and M-04 modules, and prepare a pool by yourself. Add an appropriate amount of water into the constant temperature bath as a refrigerant, turn on the power button of the constant temperature bath, set the temperature to 25°C, connect the heat exchange device and the circulation pipeline, and turn on the circulation pump B-03 to circulate and cool down. Take 10L honeysuckle water extract, put it in the raw water pool, open the valves ZF-01, ZF-04, start the low-pressure pump B-01, adjust the closing degree of the valves ZF-03, ZF-08, ZF-12 to control the feeding flow and operating pressure. Under the operating pressure of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com