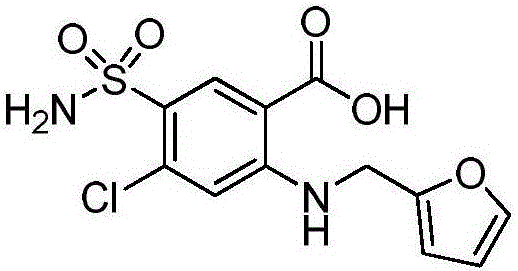

Preparation method of furosemide

A technology of furosemide and sulfonamidobenzoic acid, which is applied in the field of drug synthesis, can solve the problems of equipment corrosion by chlorosulfonic acid, large proportion of furfuramide, low total yield, etc., and achieves shortened heating time and short reaction steps. , The effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The influence of different alkalis and dosages on the reaction yield:

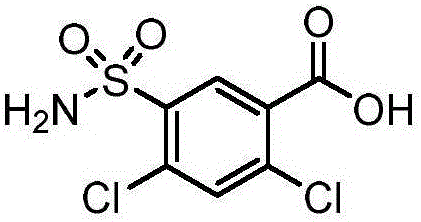

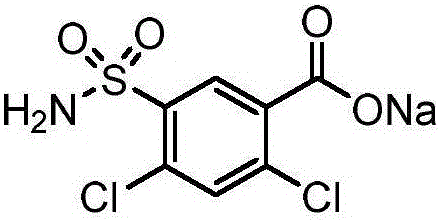

[0026] Add 200ml of absolute ethanol and alkali to a 500mL four-necked bottle with a thermometer. The selection of the alkali is shown in Table 1. After stirring and dissolving, add 27g (0.1mol) of 2,4-dichloro-5-sulfonamidobenzene formic acid, heated to 40°C and stirred for 2 hours. The reaction solution was lowered to 20-30°C and stirred for 0.5 hours, filtered, washed with 30ml of absolute ethanol, and dried to obtain 2,4-dichloro-5-sulfonamidobenzoic acid sodium salt.

[0027] Add 29.2g (0.1mol) sodium 2,4-dichloro-5-sulfonamidobenzoate, 5ml ethylene glycol, 30g (0.3mol) furfurylamine into a 100ml four-necked bottle, heat to 130-135°C and stir for 3 hours . After the reaction is completed, the solvent and furfurylamine are distilled off under reduced pressure, the reaction solution is poured into a 500ml beaker, 200ml of isopropanol is added, stirred for 30 minutes, crystallized at 0-5°C for 5...

Embodiment 2

[0032] The influence of adopting different solvents on the reaction yield:

[0033] Add 200ml of absolute ethanol and 7.14g (0.105mol) of sodium ethylate to a 500mL four-necked bottle with a thermometer, add 27g (0.1mol) of 2,4-dichloro-5-sulfonamidobenzoic acid after stirring and dissolving, and heat up The reaction was stirred at 40°C for 2 hours. The reaction solution was lowered to 20-30° C. and stirred for 0.5 hours, filtered, washed with 30 ml of absolute ethanol, and dried to obtain 2,4-dichloro-5-sulfonamidobenzoic acid sodium salt with a yield of 100%.

[0034] Add 29.2g (0.1mol) 29.2g (0.1mol) sodium 4-dichloro-5-sulfonamidobenzoate in the 100ml four-necked bottle, 5ml solvent, 30g (0.3mol) furfurylamine, the selection situation of described solvent sees Table 2, heat Stir at 130-135°C for 3 hours. After the reaction was completed, the solvent and furfurylamine were distilled off under reduced pressure, the reaction solution was poured into a 500ml beaker, 200ml of...

Embodiment 3

[0039] Adopt the influence of different isopropanol consumptions on reaction yield:

[0040] Add 200ml of absolute ethanol and 7.14g (0.105mol) of sodium ethylate to a 500mL four-necked bottle with a thermometer, add 27g (0.1mol) of 2,4-dichloro-5-sulfonamidobenzoic acid after stirring and dissolving, and heat up The reaction was stirred at 40°C for 2 hours. The reaction solution was lowered to 20-30°C and stirred for 0.5 hours, filtered, washed with 30ml of absolute ethanol, and dried to obtain 2,4-dichloro-5-sulfonamidobenzoic acid sodium salt.

[0041] Add 29.2g (0.1mol) sodium 2,4-dichloro-5-sulfonamidobenzoate, 5ml ethylene glycol, 30g (0.3mol) furfurylamine into a 100ml four-necked bottle, heat to 130-135°C and stir for 3 hours . After the reaction is complete, distill off the solvent and furfurylamine under reduced pressure, pour the reaction solution into a 500ml beaker, add a certain amount of isopropanol, see Table 3 for the amount of isopropanol, stir for 30 minut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com