Preparation method for outdoor water-borne anti-corrosive coating

An anti-corrosion coating, water-based technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of affecting the environment, irritating odor, harmful to human body, etc., and achieve the effect of long service life, no peeling, and strong coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Add 50kg of epoxy-modified acrylic water-based resin, 25kg of water-based amino resin, and 5kg of titanium dioxide into the spare pot for storing distilled water for soaking according to the weight ratio (100kg as the unit), of which 20kg of distilled water is soaked for 10 minutes After that, then add 1kg defoamer;

[0019] (2) Turn on the mixer to stir evenly. After reacting for 1 hour, slowly heat up to 60°C, then add 1kg of dispersant and 2kg of thickener respectively, and slowly heat up to 80°C while stirring evenly;

[0020] (3) After uniform stirring and reaction for 40 minutes, carry out sand milling process, and control the fineness within 60um and viscosity within 60(s);

[0021] (4) Before filtering, let the product stand for 25 minutes before filtering, and the filtering fineness should be controlled within 60um;

[0022] (5) After passing the laboratory test, it will be measured and packaged for storage.

Embodiment 2

[0024] (1) Add 56kg of epoxy-modified acrylic water-based resin, 20kg of water-based amino resin, and 6kg of titanium dioxide to the spare pot for storing distilled water for soaking according to the weight ratio (100kg as the unit), of which 22kg is distilled water, soak for 15 minutes After that, then add 1.5kg defoamer;

[0025] (2) Turn on the mixer to stir evenly. After 1.5 hours of reaction, slowly heat up to 65°C, then add 1.5kg of dispersant and 1kg of thickener, and slowly heat up to 75°C while stirring evenly. ;

[0026] (3) After uniform stirring and reaction for 45 minutes, carry out sand milling process, and control the fineness within 60um and viscosity within 60(s);

[0027] (4) Before filtering, let the product stand for 30 minutes before filtering, and the filtering fineness should be controlled within 65um;

[0028] (5) After passing the laboratory test, it will be measured and packaged for storage.

Embodiment 3

[0030] (1) Add 51kg of epoxy-modified acrylic water-based resin, 21kg of water-based amino resin, and 8kg of titanium dioxide to the spare pot for storing distilled water for 20kg of distilled water and soak for 20 minutes according to the weight ratio (100kg as the unit). After that, then add 2kg defoamer;

[0031] (2) Turn on the mixer to stir evenly. After reacting for 1 hour, slowly heat up to 65°C, then add 1.5kg of dispersant and 1.5kg of thickener, and slowly heat up to 80°C while stirring evenly. ℃;

[0032] (3) After uniform stirring and reaction for 90 minutes, carry out sand milling process, and control the fineness within 65um and viscosity within 60(s);

[0033] (4) Before filtering, let the product stand for 40 minutes before filtering, and the filtering fineness should be controlled within 65um;

[0034] (5) After passing the laboratory test, it will be measured and packaged for storage.

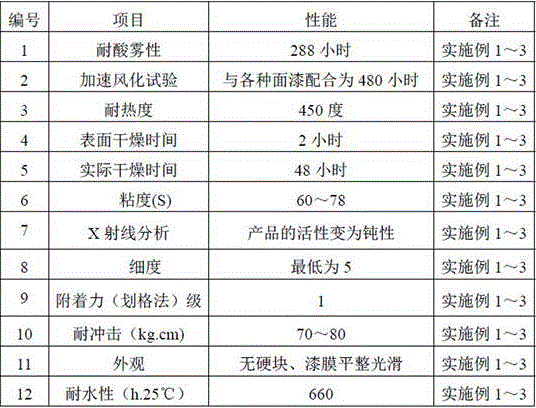

[0035] The test detection method that the product of the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com