Natural gas dewatering device

A dehydration device, natural gas technology, applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problem that zero emission cannot be achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

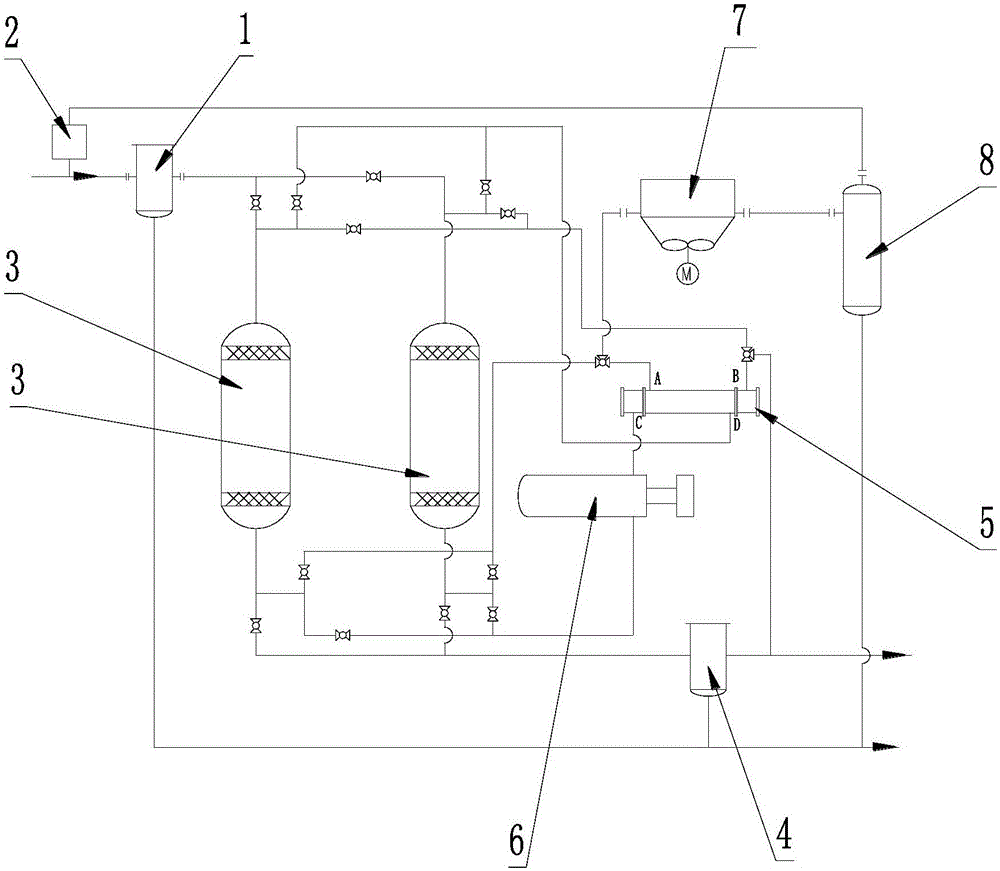

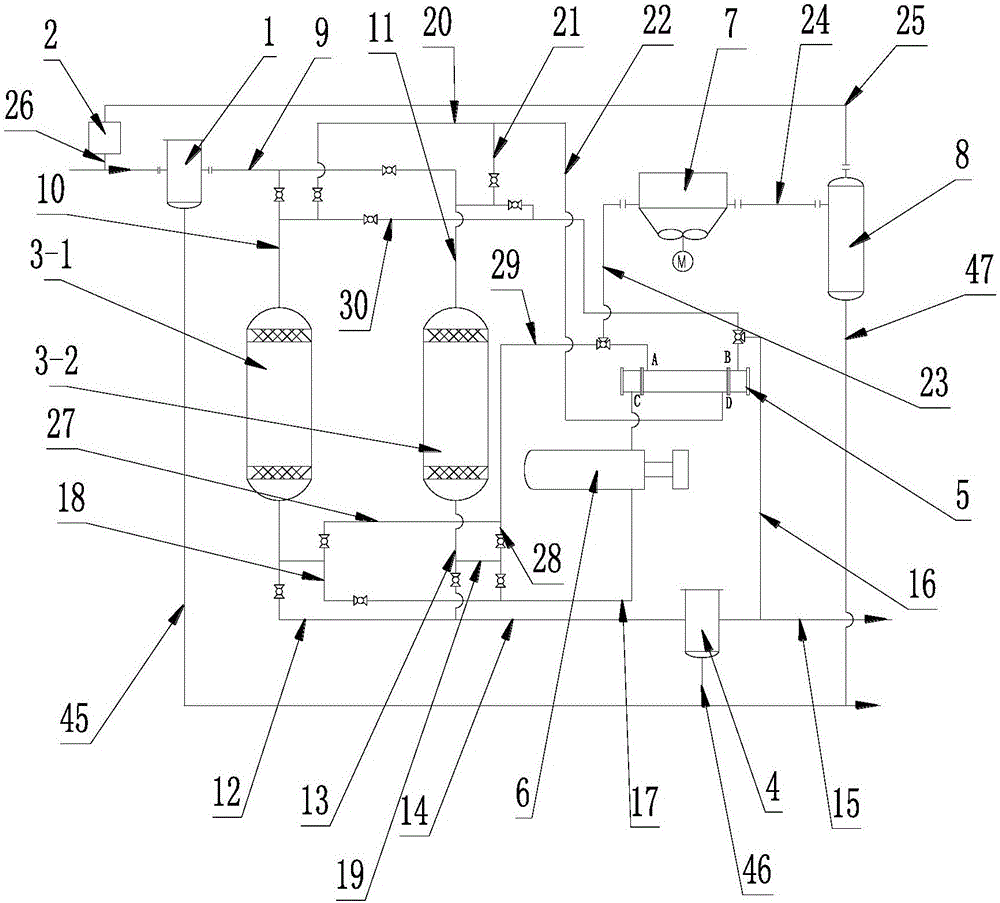

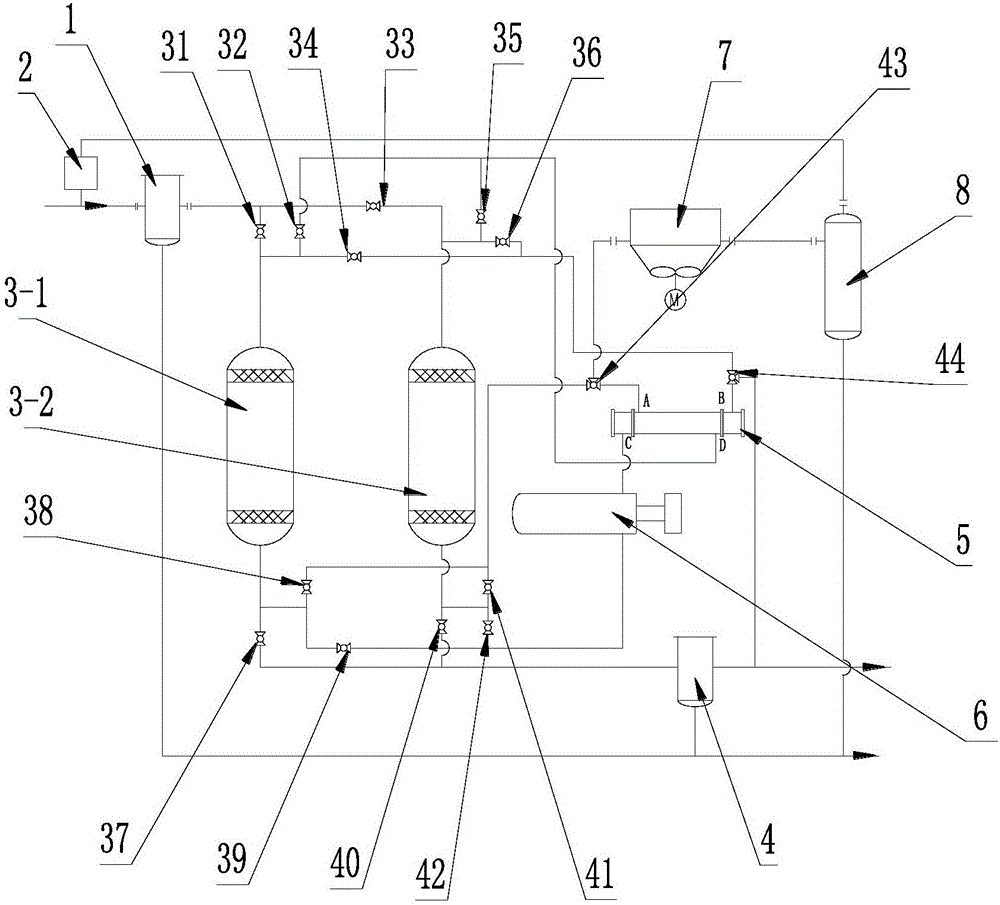

[0031] like figure 1 As shown, a natural gas dehydration device includes a first filter separator 1, two parallel molecular sieve dehydration towers 3, a second filter separator 4, a U-shaped tube heat exchanger 5, an electric heating device, a cooler 7 and a gas-liquid Separator 8; molecular sieve dehydration tower 3 is vertically arranged, molecular sieve dehydration tower 3 has dehydration tower air inlet and dehydration tower air outlet, dehydration tower air inlet is arranged on the top of molecular sieve dehydration tower 3, dehydration tower air outlet is arranged on molecular sieve dehydration Tower 3 bottom. In order to clearly describe the connection relationship, the four ports of the U-shaped tube heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com