Process for brewing jerusalem artichoke beer

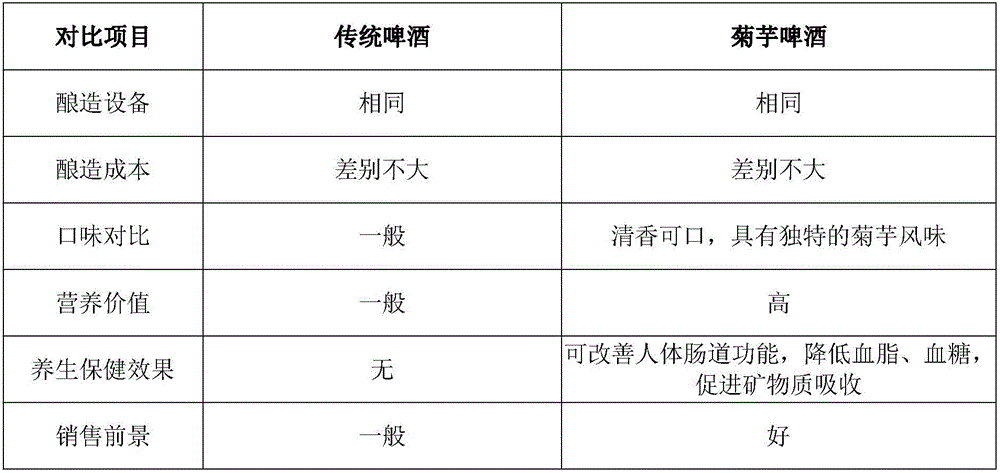

A beer and process technology, applied in the field of beverage manufacturing, can solve the problems of inability to brew fragrant and delicious Jerusalem artichoke beer, unable to meet the drinking needs of consumers, single beer taste, etc., achieve refreshing and pleasant taste, improve taste and nutritional value, nutrition rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A kind of Jerusalem artichoke beer brewing process, it comprises the following steps:

[0057] A. Preparation of yeast seed solution

[0058] In terms of parts by weight, add 0.5 parts of wort culture medium to the culture container, then activate and cultivate 0.08 parts of brewer's yeast strain on the solid medium (slant lawn) for 1.5 days, then inoculate into the culture container and incubate at 30 ° C. Vibrating culture under the conditions for 1 day, the yeast seed liquid is obtained;

[0059] B. Protein rest and glycation

[0060] In parts by weight, first weigh 20 parts of malt powder into the mash pot, add 80 parts of warm water at 50°C and mix evenly, then weigh 40 parts of Jerusalem artichoke powder into the mash pot, add 40 parts of warm water at 50°C and mix evenly, then For protein rest and saccharification, first hydrolyze at 50°C for 30 minutes, then continue to heat up to 62.5°C for 60 minutes, then continue to heat up to 68°C for 105 minutes, and the...

Embodiment 2

[0068] A kind of Jerusalem artichoke beer brewing process, it comprises the following steps:

[0069] A. Preparation of yeast seed solution

[0070] In terms of parts by weight, add 0.4 parts of wort medium to the culture container, then activate and cultivate 0.04 parts of brewer's yeast strain on the solid medium (slant lawn) for 1 day, then inoculate into the culture container and heat it at 30 ° C. Vibrating culture under the conditions for 1 day, the yeast seed liquid is obtained;

[0071] B. Protein rest and glycation

[0072] In parts by weight, first weigh 15 parts of malt powder into the mash pot, add 60 parts of warm water at 45°C and mix evenly, then weigh 30 parts of Jerusalem artichoke powder into the mash pot, add 30 parts of warm water at 45°C and mix evenly, then For protein rest and saccharification, first hydrolyze at 45°C for 40 minutes, then continue to heat up to 60°C for 70 minutes, then continue to heat up to 66°C for 120 minutes, and then continue to ...

Embodiment 3

[0080] A kind of Jerusalem artichoke beer brewing process, it comprises the following steps:

[0081] A. Preparation of yeast seed solution

[0082] In terms of parts by weight, add 0.6 parts of wort culture medium to the culture container, then activate and cultivate 0.12 parts of brewer's yeast strain on the solid medium (slant lawn) for 2 days, then inoculate it into the culture container and heat it at 30 ° C. Vibrating culture under the conditions for 1 day, the yeast seed liquid is obtained;

[0083] B. Protein rest and glycation

[0084] In parts by weight, first weigh 25 parts of malt powder into the mash pot, add 100 parts of warm water at 55°C and mix evenly, then weigh 50 parts of Jerusalem artichoke powder into the mash pot, add 50 parts of warm water at 55°C and mix evenly, then For protein rest and saccharification, first hydrolyze at 55°C for 20 minutes, then continue to heat up to 65°C for 50 minutes, then continue to heat up to 70°C for 90 minutes, and then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grinding particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com