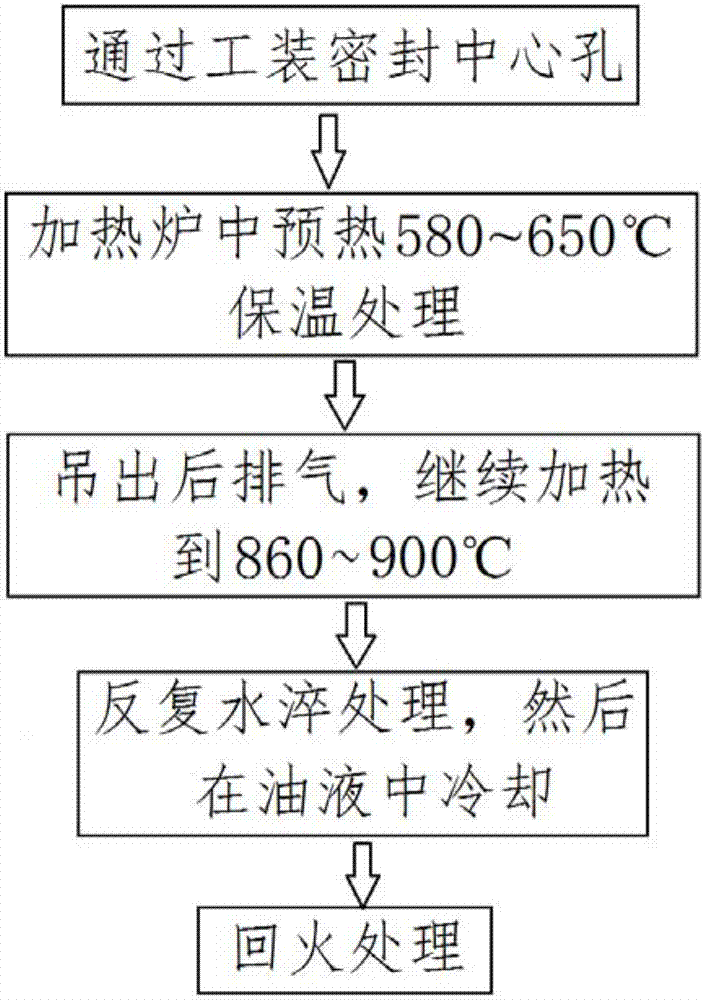

Heat treatment method of 9cr2mo straightening roll based on exhaust quenching process

A heat treatment method and technology for straightening rolls, applied in the field of straightening roll processing, can solve the problems of contradiction between processing procedures and processing effects, difficult to effectively avoid the influence of quenching medium, influence of tempering temperature, etc., to achieve good toughness, improved hardness, The effect of reducing quenching deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A heat treatment method for 9Cr2Mo straightening rollers based on the exhaust quenching process in this embodiment, the components contained in the 9Cr2Mo straightening rollers and their weight percentages are: C: 0.85%, Si: 0.23%, Mn: 0.28%, Cr : 2.1%, Mo: 0.40%, P≤0.02, S≤0.02, and the rest are iron and unavoidable impurities. The material is heat treated after forging and machining, and quenching protection is carried out by quenching tooling during the heat treatment process.

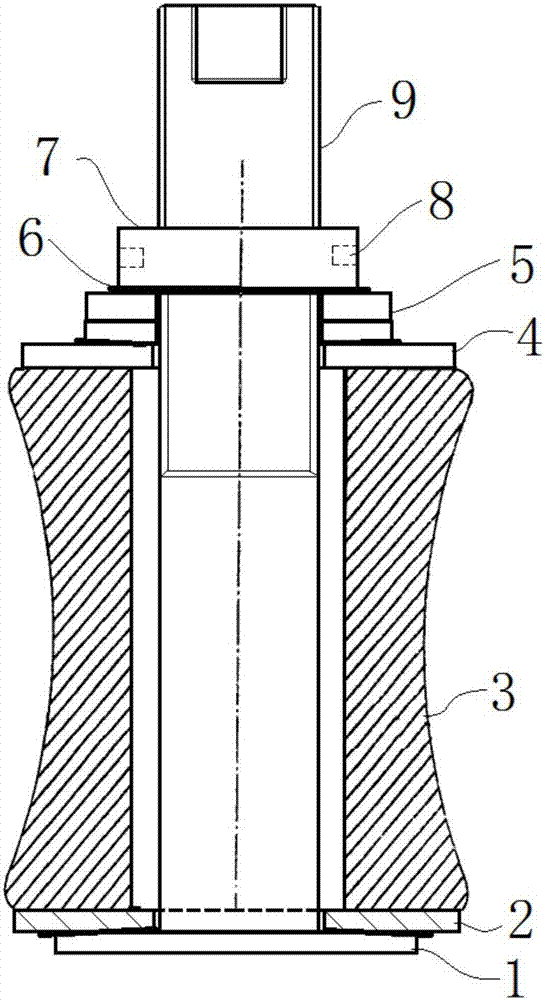

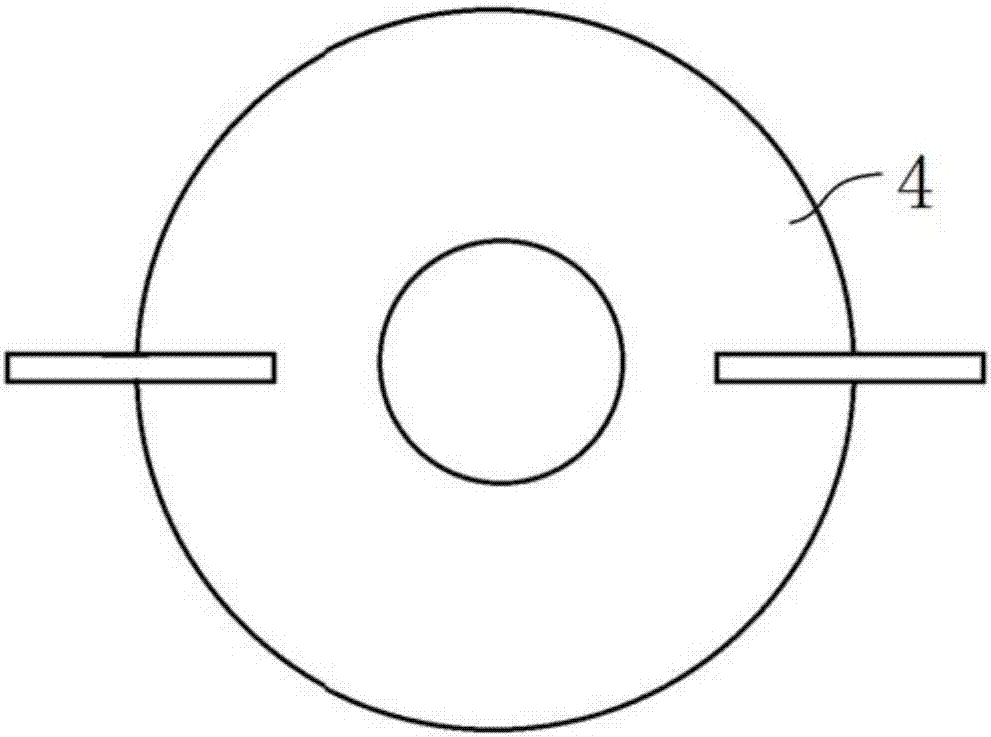

[0041] combine figure 2 , the quenching frock used in this embodiment includes a boom 9, a lower platen 2, an upper platen 4 and an inflation ring 5, the lower end of the boom 9 is connected with a baffle plate 1, and the lower end of the boom 9 is covered with a lower platen 2. When in use, Both sides of the lower platen are filled with high-temperature cotton 6 for sealing. The upper part of the suspender 9 is provided with external threads, the upper platen 4 and the inflation ring 5 ar...

Embodiment 2

[0063] In this embodiment, the radius difference between the upper platen 4, the lower platen 2, and the suspender 9 is controlled to be 1-5 mm, which is helpful for the sealing and filling of the high-temperature cotton. If the gap is too large, the high-temperature cotton is difficult to fill tightly, and the sealing effect is not good. ideal. In this embodiment, the radius difference is selected as 2 mm. The diameters of the lower pressing plate 2 and the upper pressing plate 4 are not less than 0.8 times of the diameter of the end face of the roll body 3, so as to be able to form protection for the end face of the roll body.

Embodiment 3

[0065] In this embodiment, bayonets 8 are provided on the side wall of the compression nut 7 , and the bayonets 8 are symmetrically distributed along the radial direction of the compression nut 7 . After the roller body 3 is heated, workers cannot approach it, so they can clamp the bayonet 8 by means of calipers, thereby rotating the compression nut 7 . Therefore, in step a and step c of the exhaust process, a caliper or other device can be used to snap into the bayonet 8 so as to rotate and loosen the compression nut 7 . Other structures can also be provided to assist the rotation of the compression nut 7, such as protruding blocks, slots, etc., without specific limitations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com