Acid-pickling-free hot rolled strip steel with high surface quality and manufacturing method thereof

A technology for hot-rolled strip steel and a manufacturing method, which is applied to the field of pickling-free hot-rolled strip steel and its manufacturing, can solve the problems that stamping and falling off cannot be completely avoided, the surface quality of pickling sheets and cold-rolled sheets cannot be achieved, and the like. The effect of peeling off the oxide layer, improving adhesion and formability, and excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A12、 comparative example B1-B5

[0064] Table 1 lists the structural data of the high surface quality pickling-free hot-rolled steel strips of Examples A1-A12 and the steel strips of Comparative Examples B1-B5.

[0065] Table 1.

[0066]

[0067] As can be seen from Table 1, the thickness of its pure iron layer of the high surface quality non-pickling hot-rolled steel strip of embodiment A1-A12 is 0.5-5 μ m, and the thickness of pure iron layer is less than 1 / 2nd of surface oxide layer thickness , the coverage of the pure iron layer on the iron oxide layer is greater than 70%, the thickness of the surface oxide layer is less than 20 μm, and the thickness of the inner oxide layer is less than 30 μm.

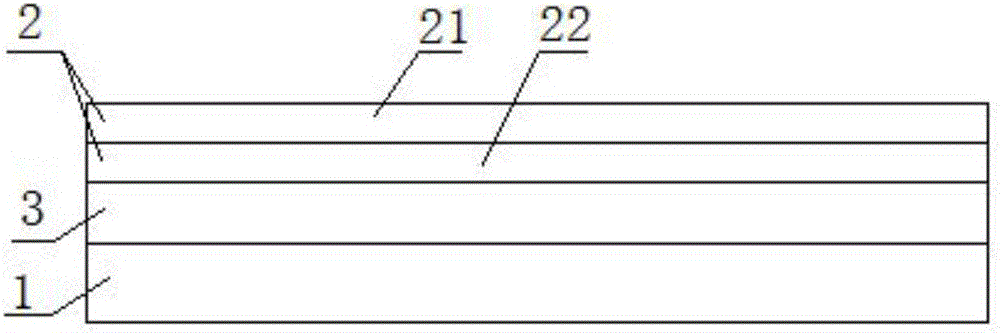

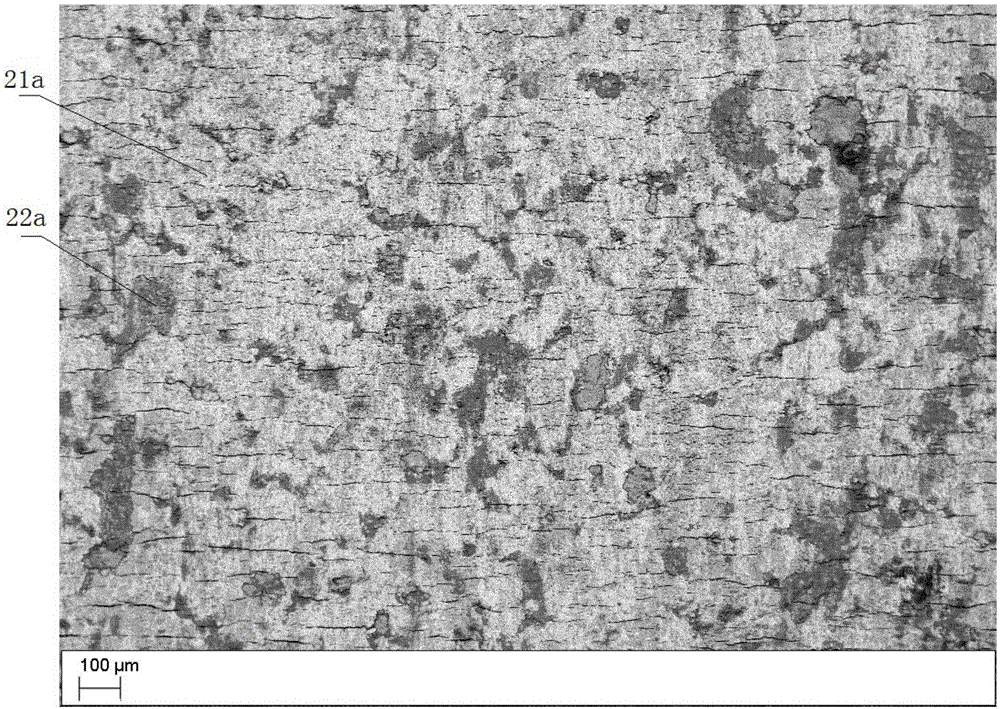

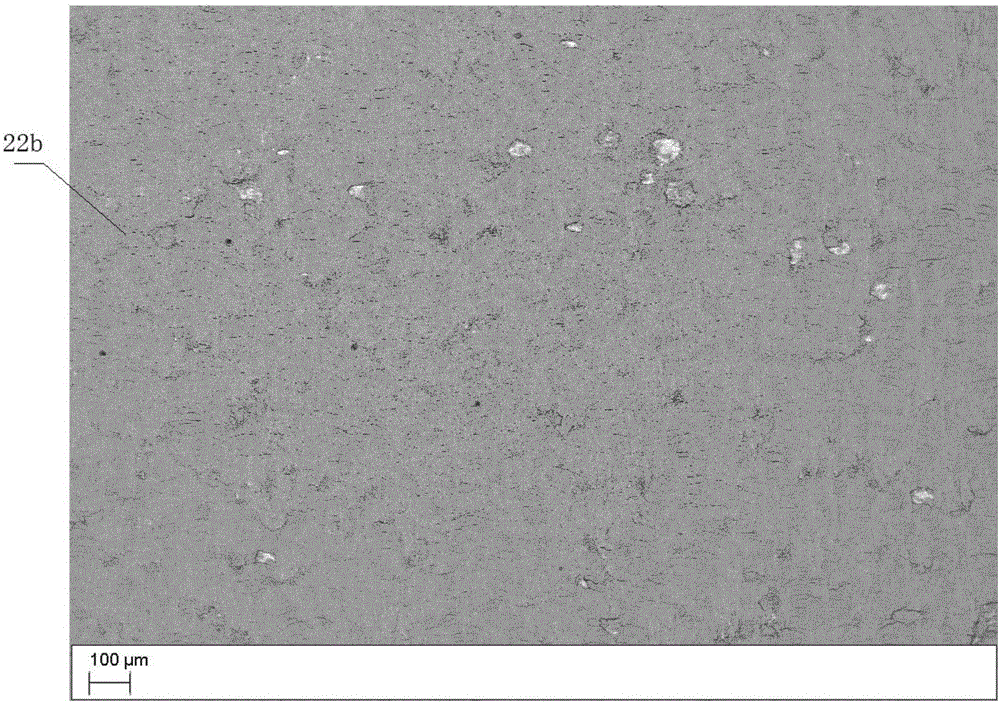

[0068] figure 2 The surface morphology of Example A1 is shown. image 3 The surface morphology of Comparative Example B1 is shown. Figure 4 The cross-sectional metallographic structure of Example A1 is shown. Figure 5 The cross-sectional metallographic structure of Comparative Example B1 is shown. Fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com