Rectangular slow wave line used for traveling wave tube

A technology of traveling wave tube and slow wave line, applied in the field of microwave vacuum electronic devices, can solve the problems of small size, narrow bandwidth and small power capacity of slow wave structure devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

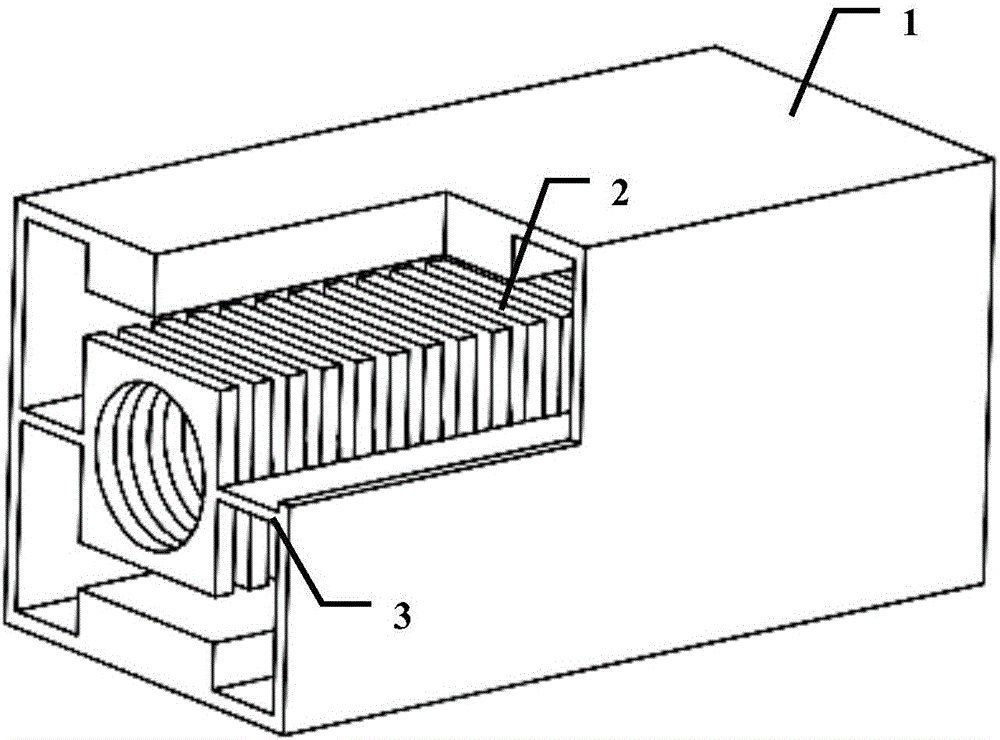

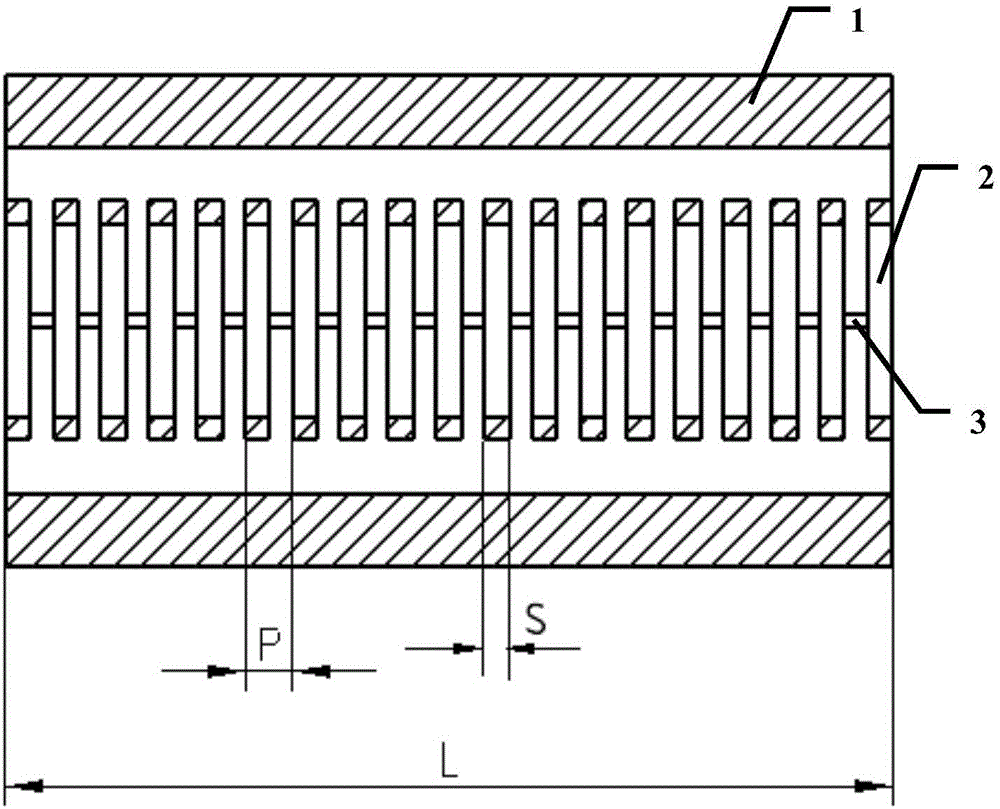

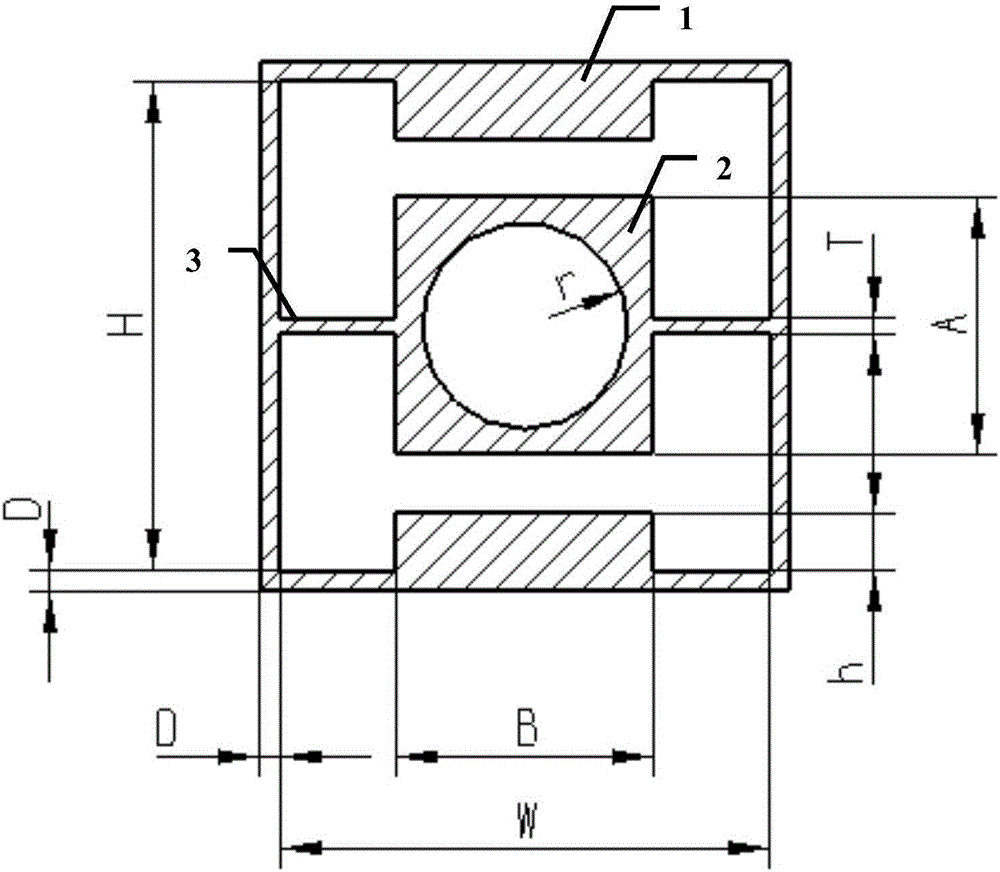

[0021] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings, so that those skilled in the art can better understand the present invention. It should be noted that in the following description, when detailed descriptions of known functions and designs may dilute the main content of the present invention, these descriptions will be omitted here.

[0022] Rectangular slow wave line (slow wave structure) as authorized on December 2, 2015, the announcement number is CN103632905B trapezoidal line structure slow wave line, because it is a kind of all metal structure slow wave line, it has good heat dissipation performance and large power capacity , in addition to its good overall structural consistency, the processing and assembly accuracy is easier to be guaranteed, so it has been widely used in millimeter wave traveling wave tubes.

[0023] The present invention is based on the above-mentioned advantages of the rectangu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com