High-orientation antimony selenide thin film and preparation method therefor

An antimony selenide, highly oriented technology, used in climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of complexity, no significant change in performance, and the inability of antimony selenide films to have orientation, etc. Achieve the effect of increased efficiency, improved current density and fill factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] Step 1. Clean the transparent conductive FTO glass with deionized water, acetone, isopropanol, and deionized water for 30 minutes each, and then dry it with a nitrogen gun;

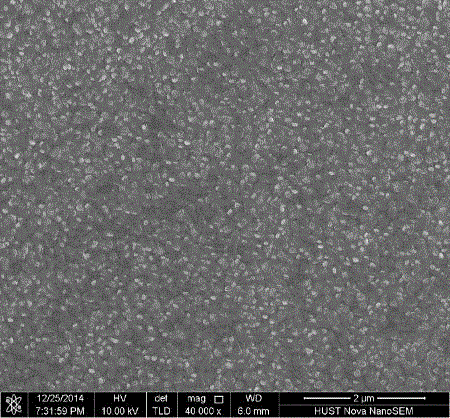

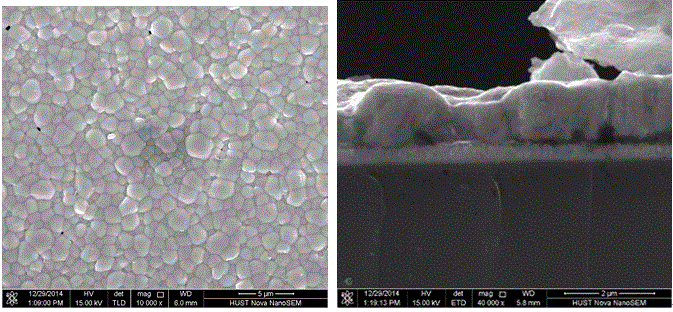

[0033] Step 2. Deposit a 300nm metal antimony thin film by thermal evaporation, the evaporation source temperature is 500-600°C, the substrate heating temperature is normal temperature, and the evaporation time is 20 minutes;

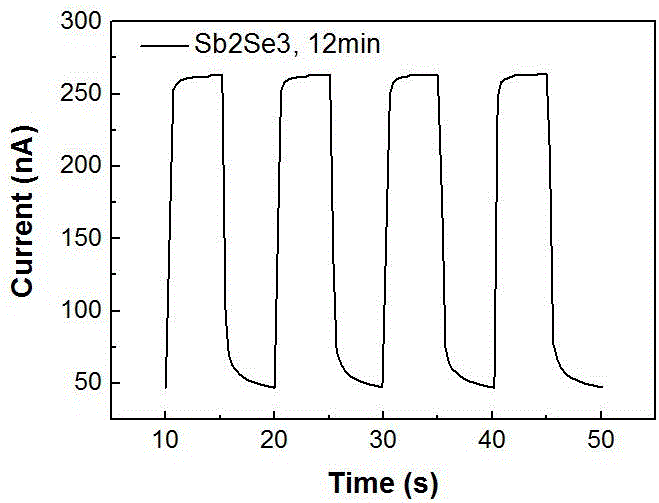

[0034] Step 3: Use a quartz cover and 50 mg of selenium particles to anneal for 16 minutes in a glove box, and then open the cover to obtain a well-oriented antimony selenide thin film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com