Processing method of bamboo shoots

A processing method and technology of bamboo shoots, applied in the field of processing bamboo shoots, can solve the problems of lack of original fragrance of bamboo shoots, dull surface of dried bamboo shoots, loss of nutrients, etc., and achieve the effects of inhibiting harmful microorganisms, maintaining color, and inhibiting browning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

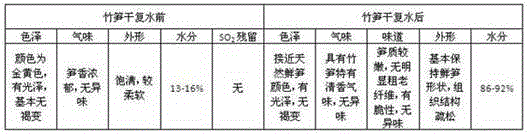

Embodiment 1

[0029] A processing method of bamboo shoots, comprising the steps of:

[0030] (1) Prepare materials, select fresh bamboo shoots, and grade them according to size, clean the surface of bamboo shoots (with shells), and remove impurities such as soil.

[0031] (2) Blanch the bamboo shoots after cleaning in 85-100°C water for 12-20 minutes to passivate the enzyme activity of the bamboo shoots, soften the fibrous tissue, inhibit harmful microorganisms, and prevent bamboo shoots from browning and lignin aging.

[0032] (3) Drain, put the blanched bamboo shoots into cold water quickly to cool them down, then remove the bamboo shells and the 2-3cm old hard parts at the base of the bamboo shoots, then wash and drain.

[0033] In this step, the bamboo shoots are dried bamboo shoots or sliced bamboo shoots. When the bamboo shoots are dried bamboo shoots, the bamboo shoots are cut in half after being cleaned.

[0034] (4) Osmosis treatment, put the bamboo shoots treated in step (3) in...

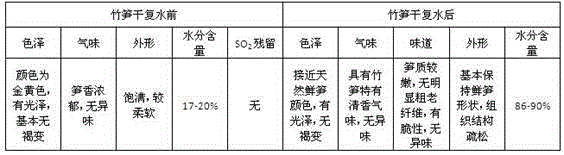

Embodiment 2

[0039] A processing method of bamboo shoots, comprising the steps of:

[0040] (1) Prepare materials, select fresh bamboo shoots, and grade them according to size, clean the surface of bamboo shoots (with shells), and remove impurities such as soil.

[0041] (2) Blanch the bamboo shoots after cleaning in 85°C water for 12 minutes to passivate the enzyme activity of the bamboo shoots, soften the fibrous tissue, inhibit harmful microorganisms, and prevent the bamboo shoots from browning and lignin aging.

[0042] (3) Drain, put the blanched bamboo shoots into cold water quickly to cool them down, then remove the bamboo shells and the 2-3cm old hard parts at the base of the bamboo shoots, then wash and drain.

[0043] In this step, the bamboo shoots are dried bamboo shoots or sliced bamboo shoots. When the bamboo shoots are dried bamboo shoots, the bamboo shoots are cut in half after cleaning, and when the bamboo shoots are slices, the bamboo shoots are sliced after cleaning,...

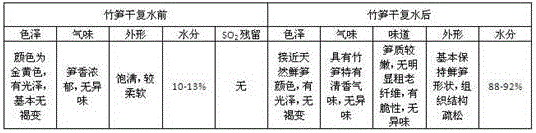

Embodiment 3

[0051] A processing method of bamboo shoots, comprising the steps of:

[0052] (1) Prepare materials, select fresh bamboo shoots, and grade them according to size, clean the surface of bamboo shoots (with shells), and remove impurities such as soil.

[0053] (2) Blanching, the bamboo shoots after cleaning are placed in 100°C water for 20 minutes to passivate the enzyme activity of bamboo shoots, soften the fibrous tissue, inhibit harmful microorganisms, and prevent bamboo shoots from browning and lignin aging.

[0054] (3) Drain, quickly put the blanched bamboo shoots into cold water to cool them down, then remove the bamboo shells and the 2-3cm old hard parts at the base of the bamboo shoots, wash and drain.

[0055] In this step, the bamboo shoots are dried bamboo shoots or sliced bamboo shoots. When the bamboo shoots are dried bamboo shoots, the bamboo shoots are cut in half after cleaning, and when the bamboo shoots are slices, the bamboo shoots are sliced after cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com