Memory alloy tube for manufacturing expandable vertebral stent

A memory alloy and vertebral body technology, which is applied in the field of memory alloy tubes, can solve the problems of filling material filling difficulties, increasing the collapsed part of the front edge, narrow tail pipe of the bracket, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

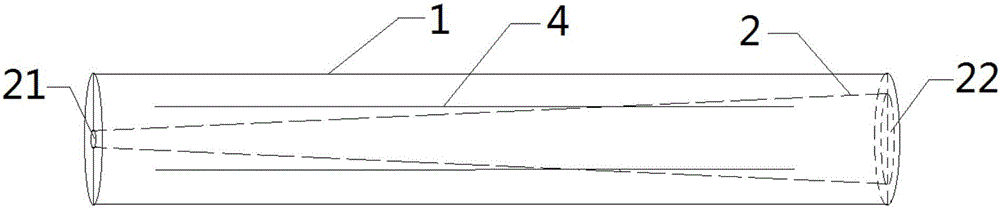

[0035] Embodiment 1: refer to figure 1 As shown, a memory alloy tube for making an expandable vertebral body stent is integrally made of nickel-titanium temperature memory alloy. Inner lumen 2; the small holes 21 and large holes 22 at both ends of the tapered inner lumen 2 are respectively located on the circular end faces of the head end 11 and the tail end 12 of the cylindrical outer tube wall, and the tapered inner lumen 2 is cut , casting mold, 3D printing technology or grinding process, when designing and considering the supporting force of the stent, the perfusion channel at the tail end 12 and the microelastic function of the stent, the design of the entire stent can be adjusted through the inclination of the tapered inner lumen 2 At the same time, the stent made of the tapered inner lumen 2, in addition to the functions of the ordinary cylindrical inner lumen 3 stent to expand and reset, restore the geometric shape of the fractured vertebral body, and generate a cavity...

Embodiment 2

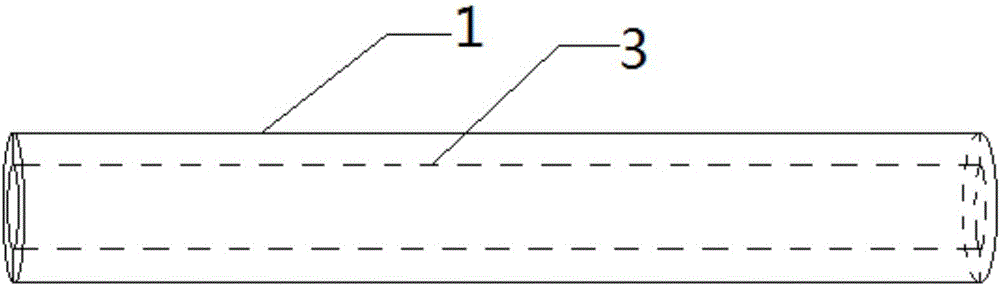

[0039] Embodiment 2: refer to figure 2 As shown, a memory alloy tube for making an expandable vertebral body stent is integrally made of nickel-titanium temperature memory alloy. The memory alloy tube includes a cylindrical outer wall tube 1 and a cylindrical outer wall tube 1 inside Inner lumen 3; the outlets at both ends of the cylindrical inner lumen 3 are respectively located on the circular end faces of the first end 11 and the tail end 12 of the cylindrical outer tube wall, and the cylindrical inner lumen 3 is cut, molded, and 3D printed technology or grinding process, refer to Figure 12 As shown, the memory alloy tube is shaped into a tubular shape in the state of ice water, implanted into the vertebral body, and can be reshaped under body temperature conditions. After reshaping and expanding, the memory alloy tube forms a certain volume space, and in Tension is generated in the vertebral body, and the fragmented, loose, and collapsed cancellous bone of the vertebral...

Embodiment 3

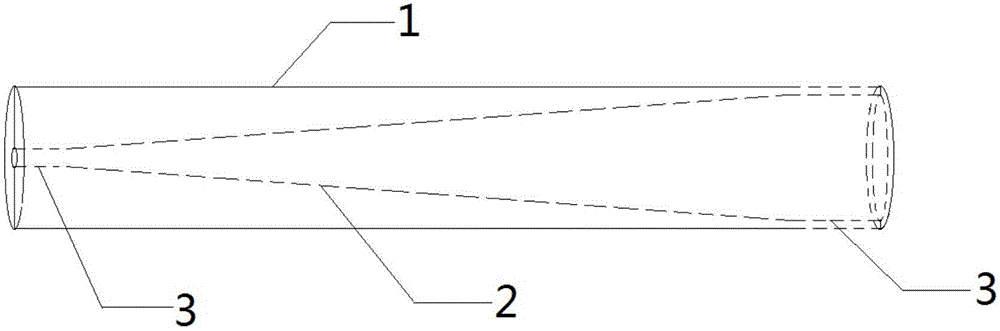

[0041] Embodiment 3: refer to image 3 As shown, a memory alloy tube for making an expandable vertebral body stent is integrally made of nickel-titanium temperature memory alloy. The memory alloy tube includes a cylindrical outer wall tube 1 and an inner tube arranged inside the cylindrical outer wall tube 1 Cavity; the outlets at both ends of the inner lumen are located on the circular end faces of the cylindrical outer tube wall head end 11 and tail end 12 respectively, and the inner lumen in the present embodiment 3 is composed of two cylindrical inner lumens 3 and the middle The tapered inner lumen 2 is formed by cutting, molding, 3D printing technology or grinding process, refer to Figure 12 As shown, the memory alloy tube is shaped into a tubular shape in the state of ice water, implanted into the vertebral body, and can be reshaped under body temperature conditions. After reshaping and expanding, the memory alloy tube forms a certain volume space, and in Tension is ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com