Bismuth telluride nanosheet loaded with cobalt nickel molybdenum particles and synthesis method thereof

A synthesis method, bismuth telluride technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of limited application, high price, etc., achieve shortened reaction time, easy operation, and solution The effect of particle agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

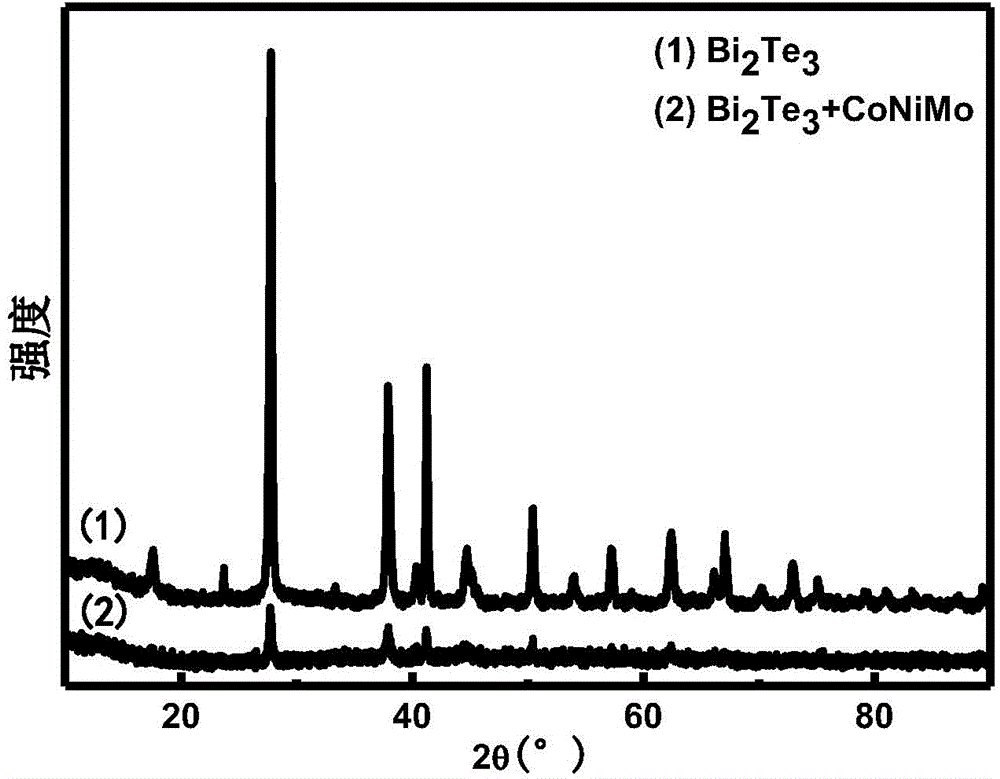

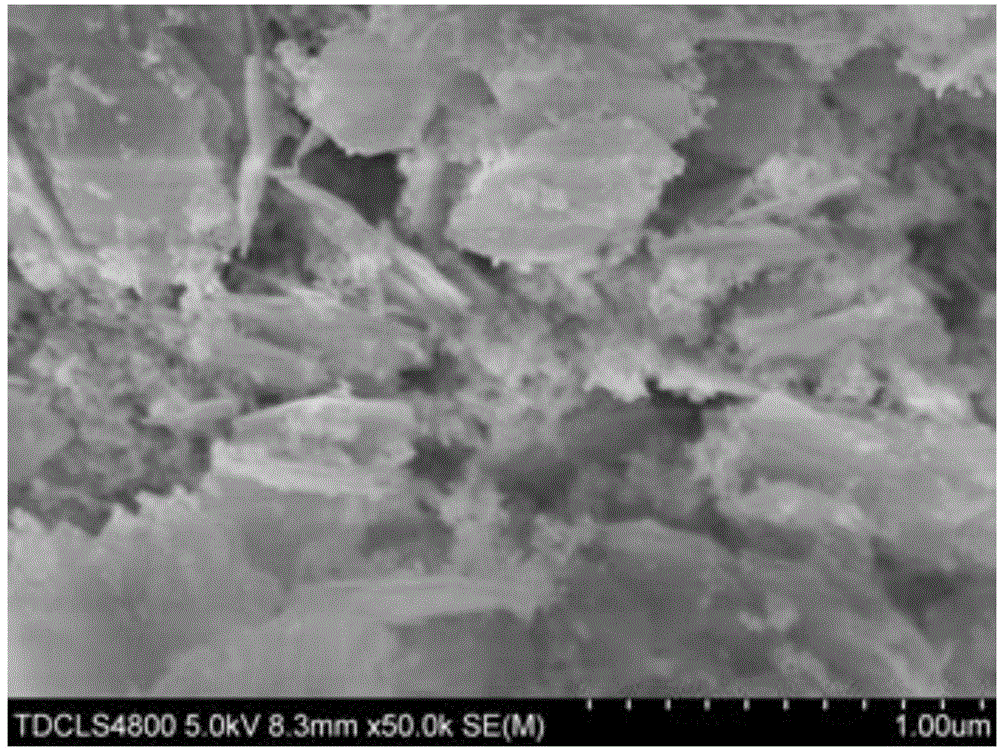

[0022] Take 0.315gBiCl 3 , 0.34gNa 2 TeO 3 , 0.48g PVP (w = 40000), 0.58g NaOH in 36ml ethylene glycol, stirred at room temperature for 2h.

[0023] Transfer the above to a polytetrafluoroethylene high-temperature reactor, and keep the temperature at 220° C. for 36 hours.

[0024] The samples were taken out, washed by centrifugation with deionized water and absolute ethanol three times, and then dried for use.

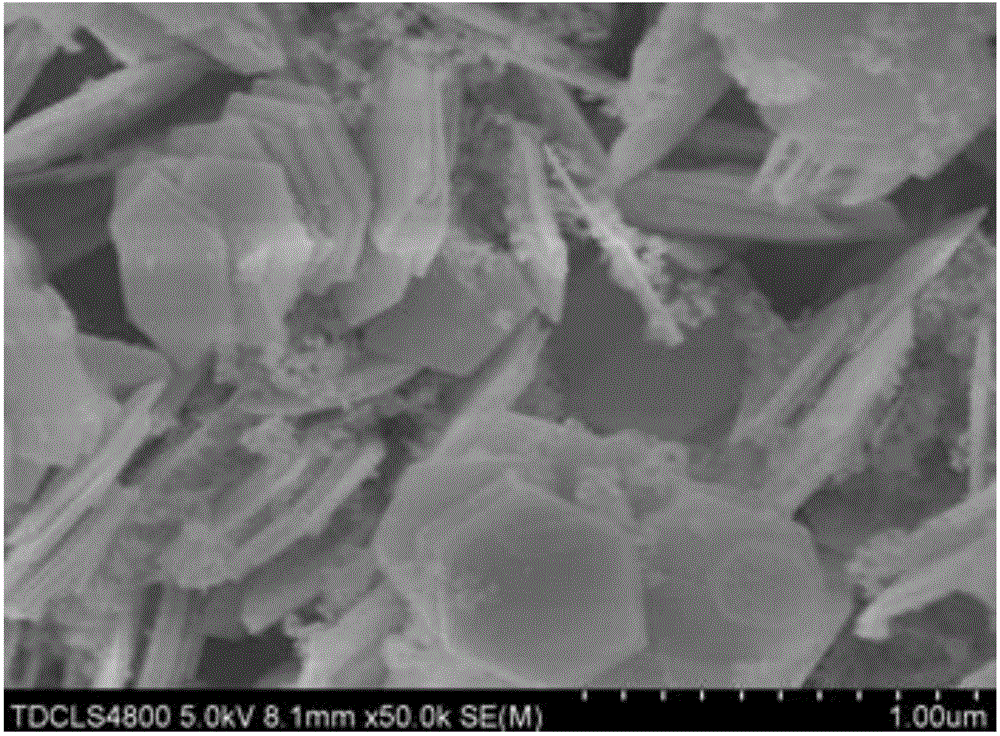

[0025] Take 0.07g of dried bismuth telluride nanoplatelets after alkali treatment and put them in the Co-Ni-Mo source mixed solution, the volume ratio of ethylene glycol: water in the mixed solution is 1:1, and the total amount of the solution is 20ml. The concentration of nickel sulfate in the solution is 0.0285M, the concentration of sodium molybdate is 0.00565M, the concentration of cobalt nitrate is 0.000694M, the concentration of trisodium citrate is 0.0249M, the concentration of PVP is 0.0000625M, stir at room temperature for 50min, and then directly Add 0.08...

Embodiment 2

[0028] Take 0.315gBiCl 3 , 0.34gNa 2 TeO 3 , 0.52g PVP (w = 40000), 0.62g NaOH in 36ml ethylene glycol, stirred at room temperature for 2h.

[0029] Transfer the above to a polytetrafluoroethylene high-temperature reactor, and keep the temperature at 220° C. for 36 hours.

[0030] The samples were taken out, washed by centrifugation with deionized water and absolute ethanol three times, and then dried for use.

[0031] Take 0.07g of dried bismuth telluride nanoplatelets after alkali treatment and put them in the Co-Ni-Mo source mixed solution, the volume ratio of ethylene glycol: water in the mixed solution is 1:1, and the total amount of the solution is 20ml. The concentration of nickel sulfate in the solution is 0.0287M, the concentration of sodium molybdate is 0.00567M, the concentration of cobalt nitrate is 0.00694M, the concentration of trisodium citrate is 0.0251M, the concentration of PVP is 0.0000625M, stir at room temperature for 70min, and then directly Add 0.08g...

Embodiment 3

[0034] Take 0.315gBiCl 3 , 0.34gNa 2 TeO 3 , 0.50g PVP (w = 40000), 0.60g NaOH in 36ml ethylene glycol, stirred at room temperature for 2h.

[0035] Transfer the above to a polytetrafluoroethylene high-temperature reactor, and keep the temperature at 220° C. for 36 hours.

[0036] The samples were taken out, washed by centrifugation with deionized water and absolute ethanol three times, and then dried for use.

[0037] Take 0.07g of dried bismuth telluride nanoplatelets after alkali treatment and put them in the Co-Ni-Mo source mixed solution, the volume ratio of ethylene glycol: water in the mixed solution is 1:1, and the total amount of the solution is 20ml. The concentration of nickel sulfate in the solution is 0.0286M, the concentration of sodium molybdate is 0.00566M, the concentration of cobalt nitrate is 0.0347M, the concentration of trisodium citrate is 0.0250M, the concentration of PVP is 0.0000625M, stir at room temperature for 60min, and then directly Add 0.08g ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com