Multifunctional polishing machine

A polishing machine, multi-functional technology, applied in the direction of grinding/polishing equipment, grinding/polishing safety devices, grinding machines, etc., can solve the problem of easy grinding between the grinding tool and the metal workpiece, and the processing function of a single grinding tool is less , affect the processing quality and other issues, achieve the effect of convenient tool change, reduce calculation and setting time, and avoid human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

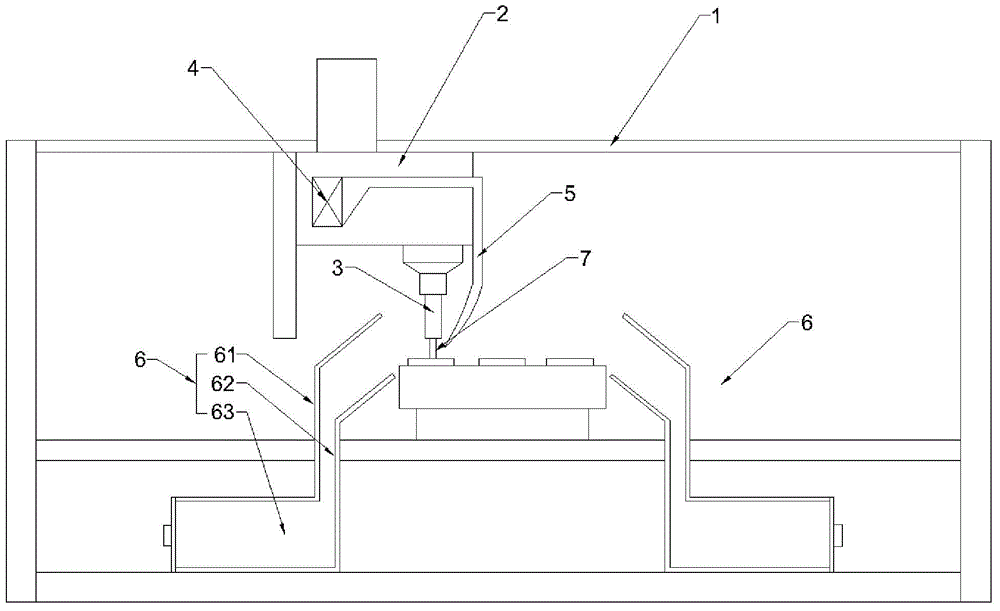

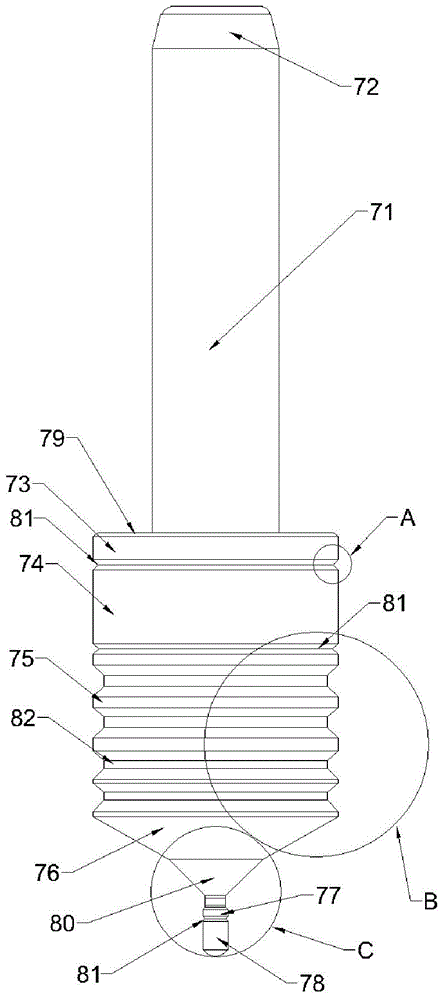

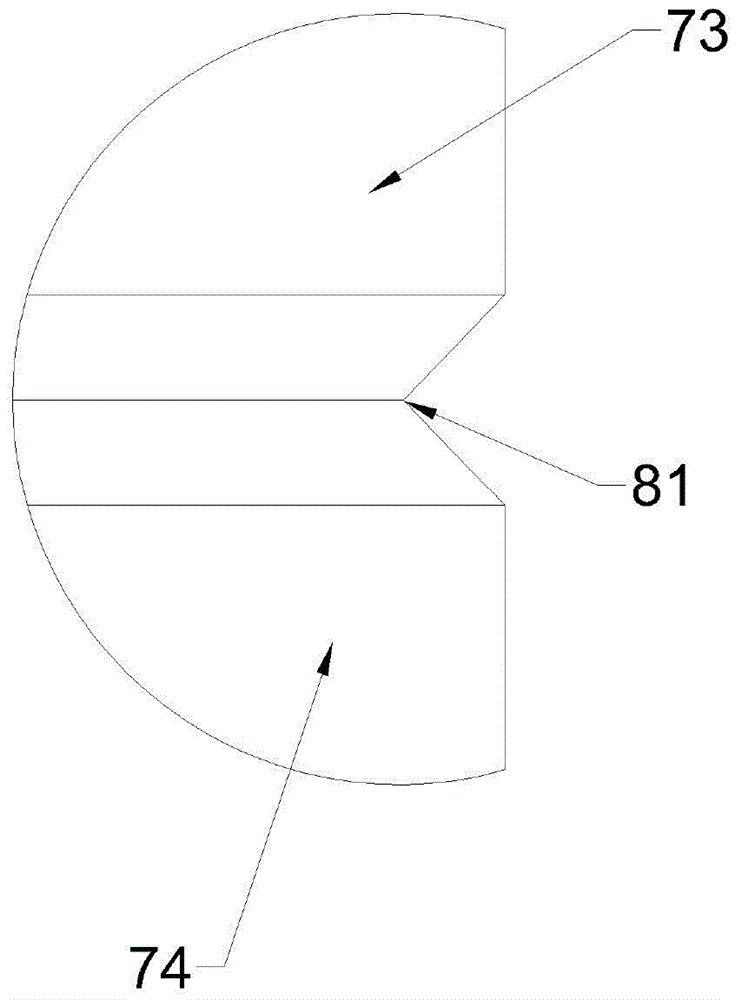

[0019] See Figure 1-5 , A multifunctional polishing machine, including a main frame 1, the main frame 1 is provided with a spindle drive part 2 that can move in the vertical and horizontal directions, and further, the spindle drive part 2 can be controlled by a numerical control device and automatically Vertical movement and horizontal movement to automatically grind the workpiece, the spindle drive part 2 drives a transmission spindle 3 to rotate, the transmission spindle 3 is located above the workpiece, and the end of the transmission spindle 3 is equipped with a grinding tool 7. The grinding tool 7 includes a tool holder 71, which facilitates the clamping of the tool on the spindle of the machining center. The upper end of the tool holder 71 has a tool guide portion 72, which is tapered, and its upper end has a circular arc chamfer, which can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com