Flame-retardant and explosion-proof artificial quartz stone

An artificial quartz stone, flame-retardant and explosion-proof technology, which is applied in the field of artificial stone production, can solve the problems of few artificial quartz stones, and achieve the effects of superior flame retardancy, low adhesion, and good gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

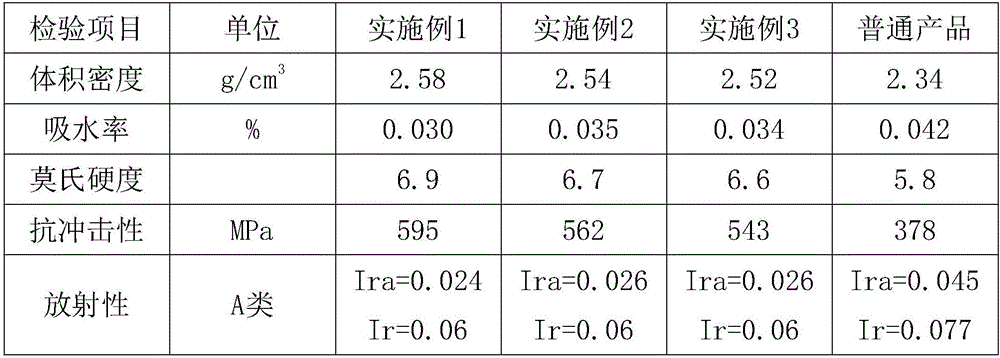

Examples

Embodiment 1

[0018] A flame-retardant and explosion-proof artificial quartz stone, made of the following components by weight (kg): 58 parts of 20-50 mesh calcined quartz sand, 38 parts of 50-100 mesh calcined clay, 21 parts of 20-50 mesh titanium dioxide powder, 9 parts of modified binder, 22 parts of composite resin, 12 parts of curing agent, 12 parts of modified flame retardant, and 3 parts of colorant.

[0019] The modified adhesive is prepared by mixing gamma-chloropropyltrimethoxysilane, sodium carboxymethylcellulose and a-cyanoacrylate in equal parts.

[0020] The composite resin is prepared by mixing dilute acid-modified alkyd resin, chlorinated unsaturated polyester resin and phthalic acid polyester resin in equal parts.

[0021] The curing agent is at least one of tert-butyl peroxy-2-ethylhexanoate, aminoethylpiperazine, and dipropylenetriamine.

[0022] The modified flame retardant is prepared by mixing nano-magnesium hydroxide and N,N-dimethyl-hexadecyl-vinylbenzyl-ammonium ch...

Embodiment 2

[0029] A flame-retardant and explosion-proof artificial quartz stone is made of the following components by weight (kg): 55 parts of 20-50 mesh calcined quartz sand, 35 parts of 50-100 mesh calcined clay, 18 parts of 20-50 mesh titanium dioxide powder, 6 parts of modified binder, 18 parts of composite resin, 10 parts of curing agent, 10 parts of modified flame retardant, and 3 parts of colorant.

[0030] The modified adhesive is prepared by mixing gamma-chloropropyltrimethoxysilane, sodium carboxymethylcellulose and a-cyanoacrylate in equal parts.

[0031] The composite resin is prepared by mixing dilute acid-modified alkyd resin, chlorinated unsaturated polyester resin and phthalic acid polyester resin in equal parts.

[0032] The curing agent is at least one of tert-butyl peroxy-2-ethylhexanoate, aminoethylpiperazine, and dipropylenetriamine.

[0033] The modified flame retardant is prepared by mixing nano-magnesium hydroxide and N,N-dimethyl-hexadecyl-vinylbenzyl-ammonium ...

Embodiment 3

[0040] A flame-retardant and explosion-proof artificial quartz stone is made of the following components by weight (kg): 62 parts of 20-50 mesh calcined quartz sand, 42 parts of 50-100 mesh calcined clay, 24 parts of 20-50 mesh titanium dioxide powder, 12 parts of modified binder, 26 parts of composite resin, 15 parts of curing agent, 15 parts of modified flame retardant, and 4 parts of colorant.

[0041] The modified adhesive is prepared by mixing gamma-chloropropyltrimethoxysilane, sodium carboxymethylcellulose and a-cyanoacrylate in equal parts.

[0042] The composite resin is prepared by mixing dilute acid-modified alkyd resin, chlorinated unsaturated polyester resin and phthalic acid polyester resin in equal parts.

[0043] The curing agent is at least one of tert-butyl peroxy-2-ethylhexanoate, aminoethylpiperazine, and dipropylenetriamine.

[0044] The modified flame retardant is prepared by mixing nano-magnesium hydroxide and N,N-dimethyl-hexadecyl-vinylbenzyl-ammonium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com