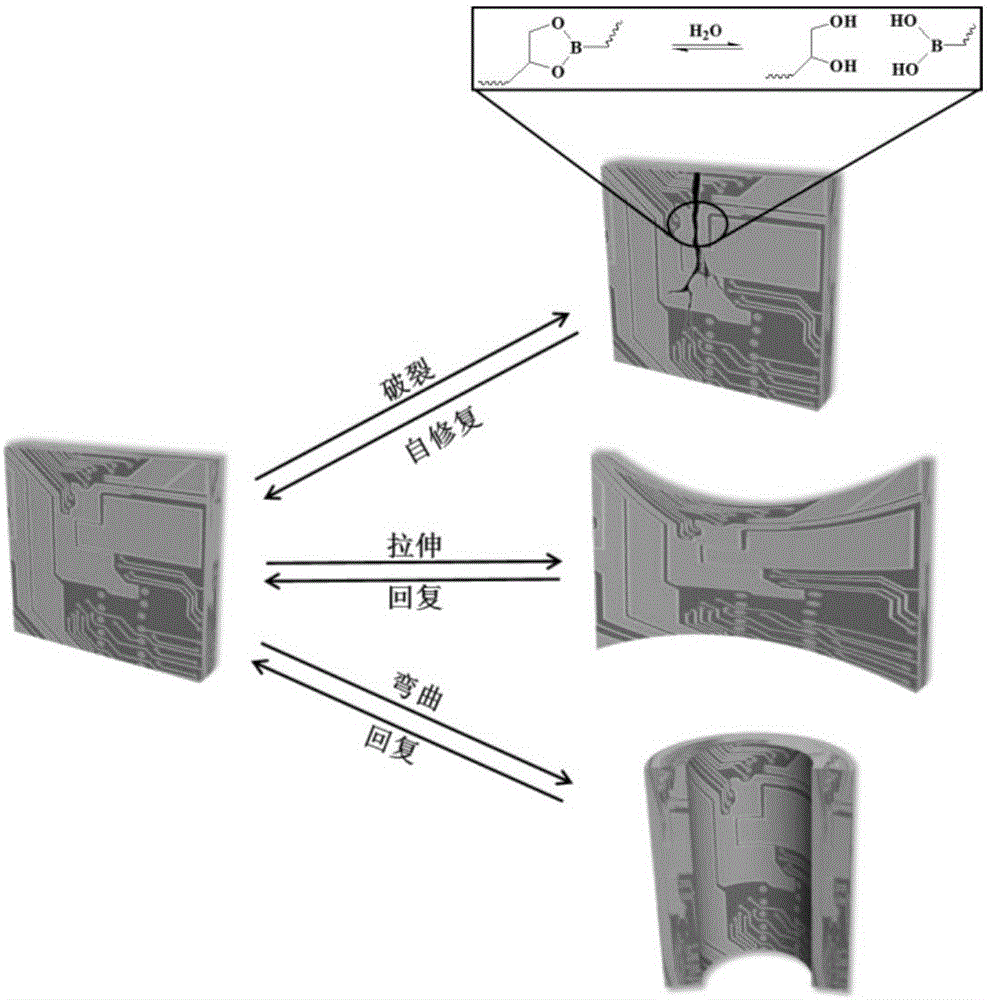

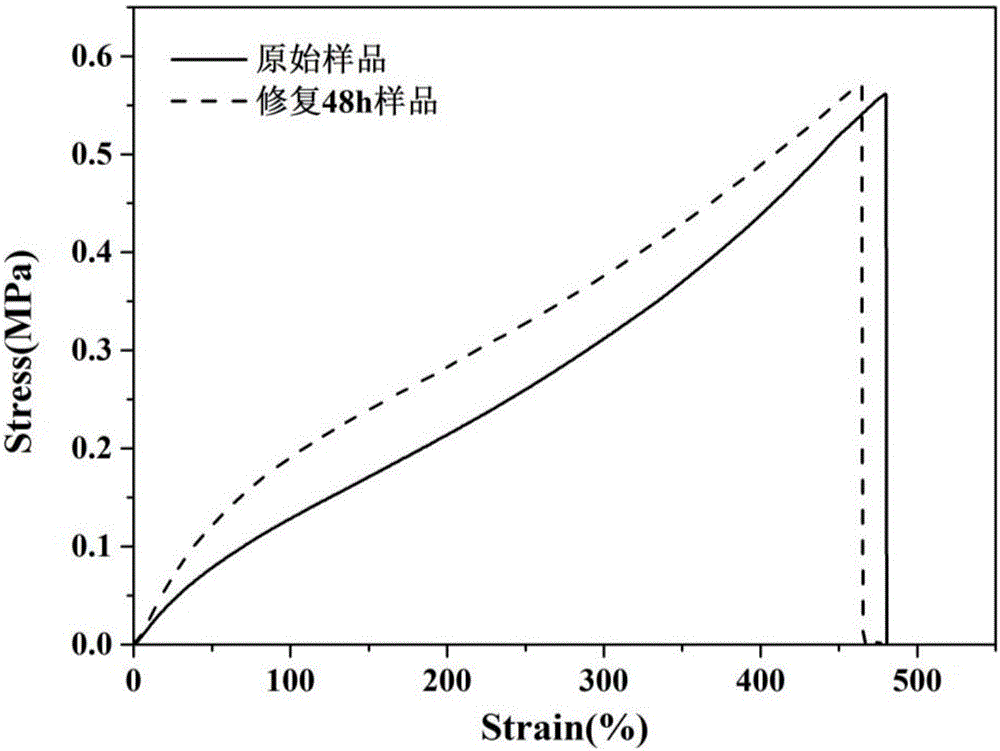

Self-repairing flexible printed circuit board and preparation method thereof

A flexible printed circuit, self-healing technology, applied in flexible printed circuit boards, printed circuits, printed circuit components, etc., can solve problems such as performance degradation and scrapping, and achieve low cost, excellent mechanical properties, and simple and easy preparation methods. row effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing a self-repairing flexible printed circuit board, said method comprising the following steps:

[0030] (1) Put 9g of N,N-dimethylacrylamide, 1g of 2-hydroxyethyl acrylate, 0.25g of borax, 4g of water and 0.05g of 2,2-diethoxyacetophenone into the container in proportion, and use The mixer was shaken and stirred for 5 minutes, and then nitrogen gas was passed into the solution for 3 minutes;

[0031] (2) Place the mixed solution obtained in step (1) in a self-made mold, and use a 254nm ultraviolet lamp to irradiate for 18 minutes to obtain a self-healing hydrogel elastomer based on a borate bond;

[0032] (3) Using the self-healing hydrogel elastomer based on borate ester bonds obtained in step (2) as a base material, the self-healing flexible printed circuit board can be obtained through printed circuit technology.

[0033] The self-made mold is made by sandwiching a silicone ring between two glass plates, the size of the glass plate is 30mm×75mm×...

Embodiment 2

[0035] A method for preparing a self-repairing flexible printed circuit board, said method comprising the following steps:

[0036] (1) Put 7g of N,N-dimethylacrylamide, 3g of hydroxyethyl methacrylate, 0.75g of borax, 4g of water and 0.05g of 2,2-diethoxyacetophenone into the container in proportion, and use a mixing Shake and stir for 10 minutes with a homogenizer, and then pass nitrogen gas into the solution for 5 minutes;

[0037] (2) Place the mixed solution obtained in step (1) in a self-made mold, and use a 254nm ultraviolet lamp to irradiate for 15 minutes to obtain a self-healing hydrogel elastomer based on a borate bond;

[0038] (3) Using the self-healing hydrogel elastomer based on borate ester bonds obtained in step (2) as a base material, the self-healing flexible printed circuit board can be obtained through printed circuit technology.

[0039] The self-made mold is made by sandwiching a silicone ring between two glass plates, the size of the glass plate is 30m...

Embodiment 3

[0041] A method for preparing a self-repairing flexible printed circuit board, said method comprising the following steps:

[0042] (1) Put 5g of acrylamide, 5g of hydroxypropyl methacrylate, 1.25g of borax, 6g of water and 0.05g of 2,2-diethoxyacetophenone into the container in proportion, and use a mixer to shake and stir for 8min. Nitrogen was passed through the solution for 4 minutes;

[0043] (2) Place the mixed solution obtained in step (1) in a self-made mold, and use a 254nm ultraviolet lamp to irradiate for 20 minutes to obtain a self-healing hydrogel elastomer based on a borate bond;

[0044] (3) Using the self-healing hydrogel elastomer based on borate ester bonds obtained in step (2) as a base material, the self-healing flexible printed circuit board can be obtained through printed circuit technology.

[0045] The self-made mold is made by sandwiching a silicone ring between two glass plates, the size of the glass plate is 30mm×75mm×1mm, and the thickness of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com